Method and system for powering a vehicle

一种车辆、供能的技术,应用在用于为车辆供能和系统领域,能够解决变压器占用体积等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

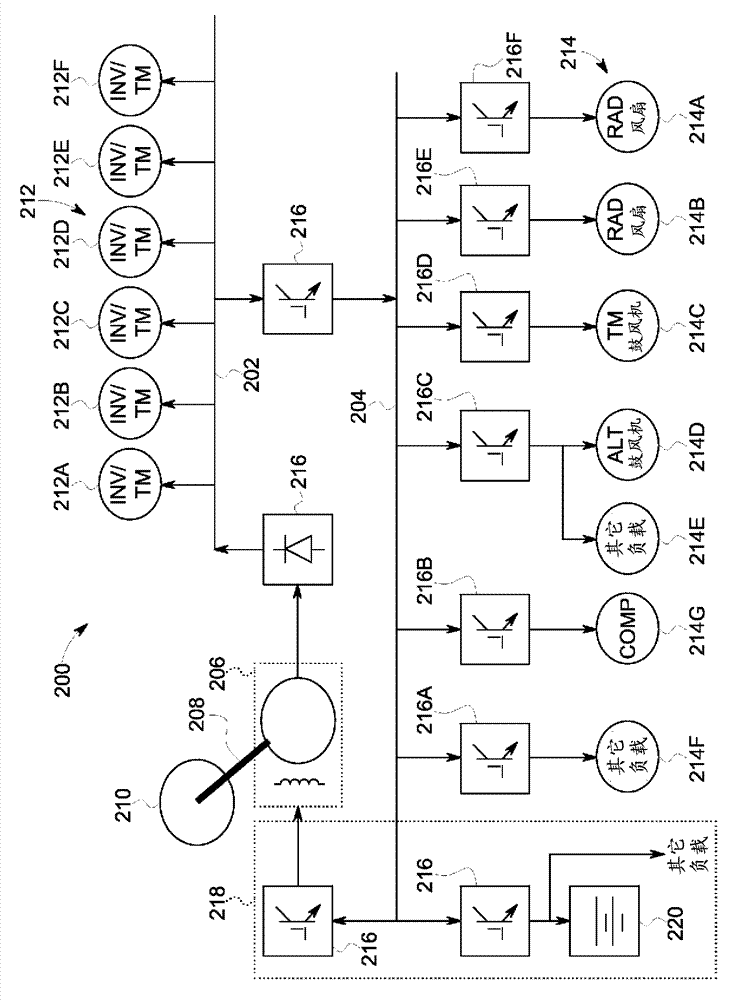

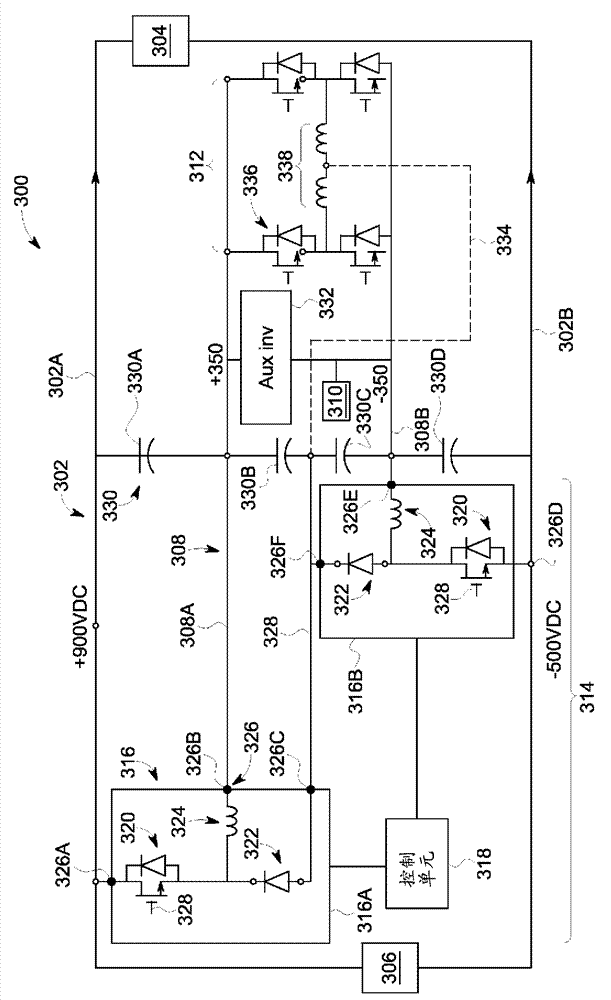

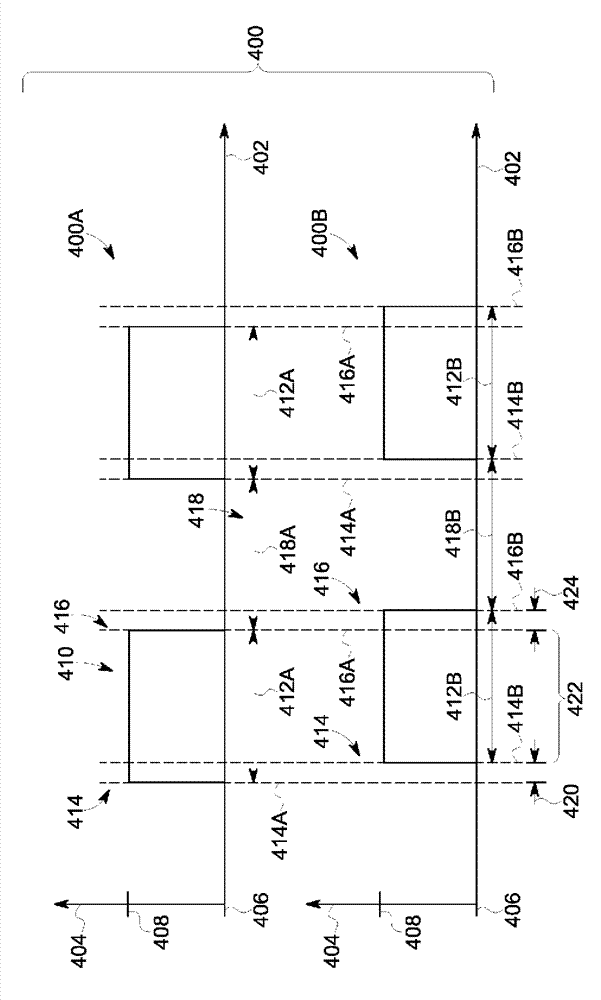

[0016] One or more embodiments of the subject matter of the invention described herein provide a system and method that converts a relatively high voltage transmitted along a traction bus (for example, for powering a traction motor of a vehicle) into A smaller voltage is delivered along the auxiliary bus in order to power non-traction motors (for example, motors that operate at a smaller voltage to perform work that does not involve propelling the vehicle). For example, a voltage of 1400 volts (or another high voltage) can be transferred from one bus to another bus, where the transferred voltage is reduced to 700 volts (or another low voltage) to power non-traction motors. The high voltage on the traction bus can be reduced to a smaller voltage on the auxiliary bus without the need to transmit the high voltage through filters, transformers, etc., and / or the need to modify the non-traction motor to accept the high voltage. For example, a standard (e.g., not modified after purcha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com