Light storage luminous typepolyvinyl chloride dip composite and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of weak luminous intensity, blackening and falling off of products, shorten the friction force and time, and have good chemical stability , solve the effect of blackening

Active Publication Date: 2014-12-31

CHINA PETROLEUM & CHEM CORP

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, compared with plastic dipping, the plastic layer attached to the metal layer is thinner

The thinner plastic layer is easy to fall off when scratched, and there is less light-storing luminescent powder in it, resulting in weaker luminous intensity and shorter luminous time

And due to the poor h

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

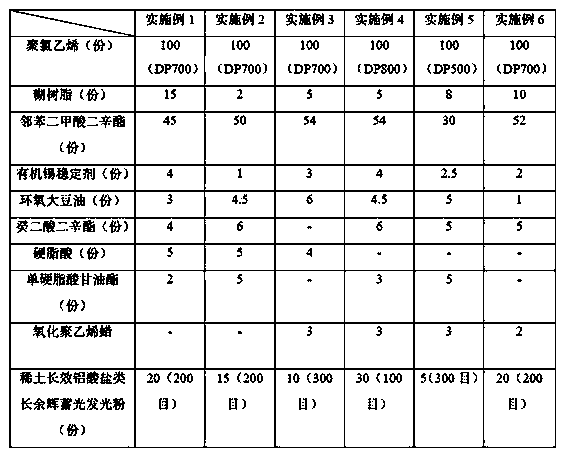

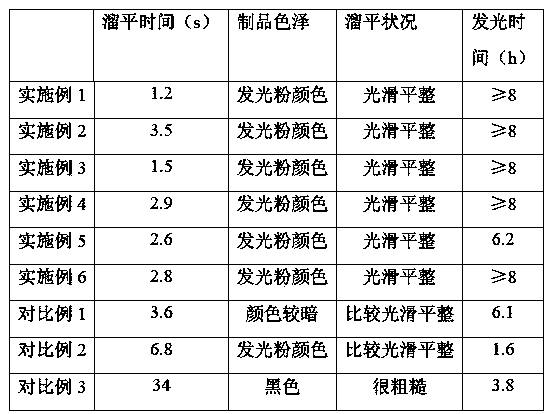

The invention relates to a light storage luminous typepolyvinyl chloride dip composite and a preparation method thereof, which belong to the technical field of high-molecular material processing application. The light storage luminous typepolyvinyl chloride dip composite is prepared by mixing 100 parts of suspension method polyvinyl chloride resin with polymerization degree of 500-800, 2-15 parts of PVC paste resins, 1-8 parts of stabilizing agent, 1-6 parts of epoxy soybean oil, 35-65 parts of phthalate esters plasticizer and dioctyl sebacate complex formulation plasticizer, 2-10 parts of lubricant and 5-30 parts of rare earth long-acting aluminate long afterglow light storing luminescent powder with 100-300 meshes. The preparation comprises the following steps: mixing the rare earth long-acting aluminate long afterglow light storing luminescent powder and a liquid auxiliary agent, and adding the liquid auxiliary agent of other components at anaphase of batch mixing and then blending. The composite can realize the dip preparation of a light storing material, and is firmly bound with metal after dip is carried out, and the luminescence time can be long.

Description

technical field [0001] A light-storing and light-emitting polyvinyl chloride plastic dipping composition and a preparation method thereof belong to the technical field of polymer material processing and application. Background technique [0002] Plastic dipping is a processing method in which the surface-treated metal products are dipped into resin powder or resin paste in a preheated state, and the resin on the surface of the metal layer is heated and plasticized to obtain a plastic coating on the surface. Light-storing materials refer to materials that store energy in materials after being irradiated by sunlight or light, and release energy in the form of light at night or in dark places. This kind of luminous plastic is mostly processed by adding light-storing and luminescent pigments to plastics, and is mainly used for safety signs, billboards, handicrafts, traffic instructions, guardrails and fences. [0003] At present, light-storing materials are mostly used for powd...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08K13/02C08K3/24C08K5/1515C08K5/12C09K11/06

Inventor 桂俊杰李静刘荣德张桦刘浩孙培培王秀丽孙丽朋

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com