Fixed plate of pcb board and its processing method

A technology of PCB board and processing method, which is applied in the field of fixed board and its processing, to achieve the effects of reducing processing time, compact product structure, and simplifying changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

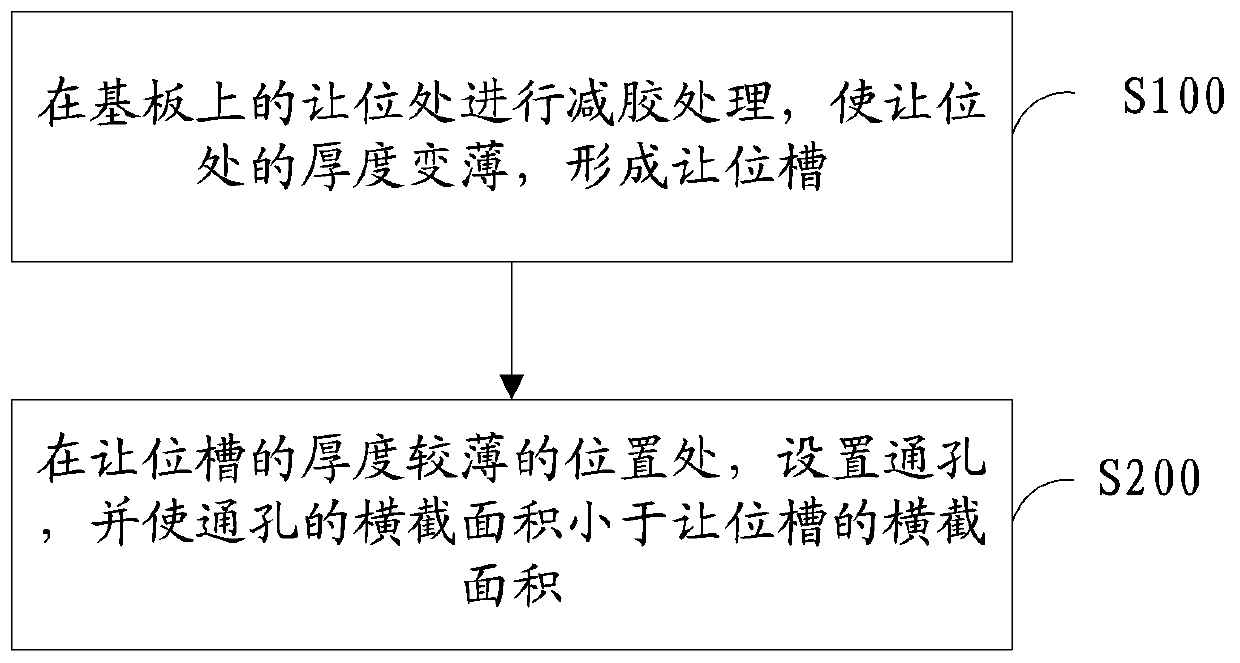

Method used

Image

Examples

Embodiment Construction

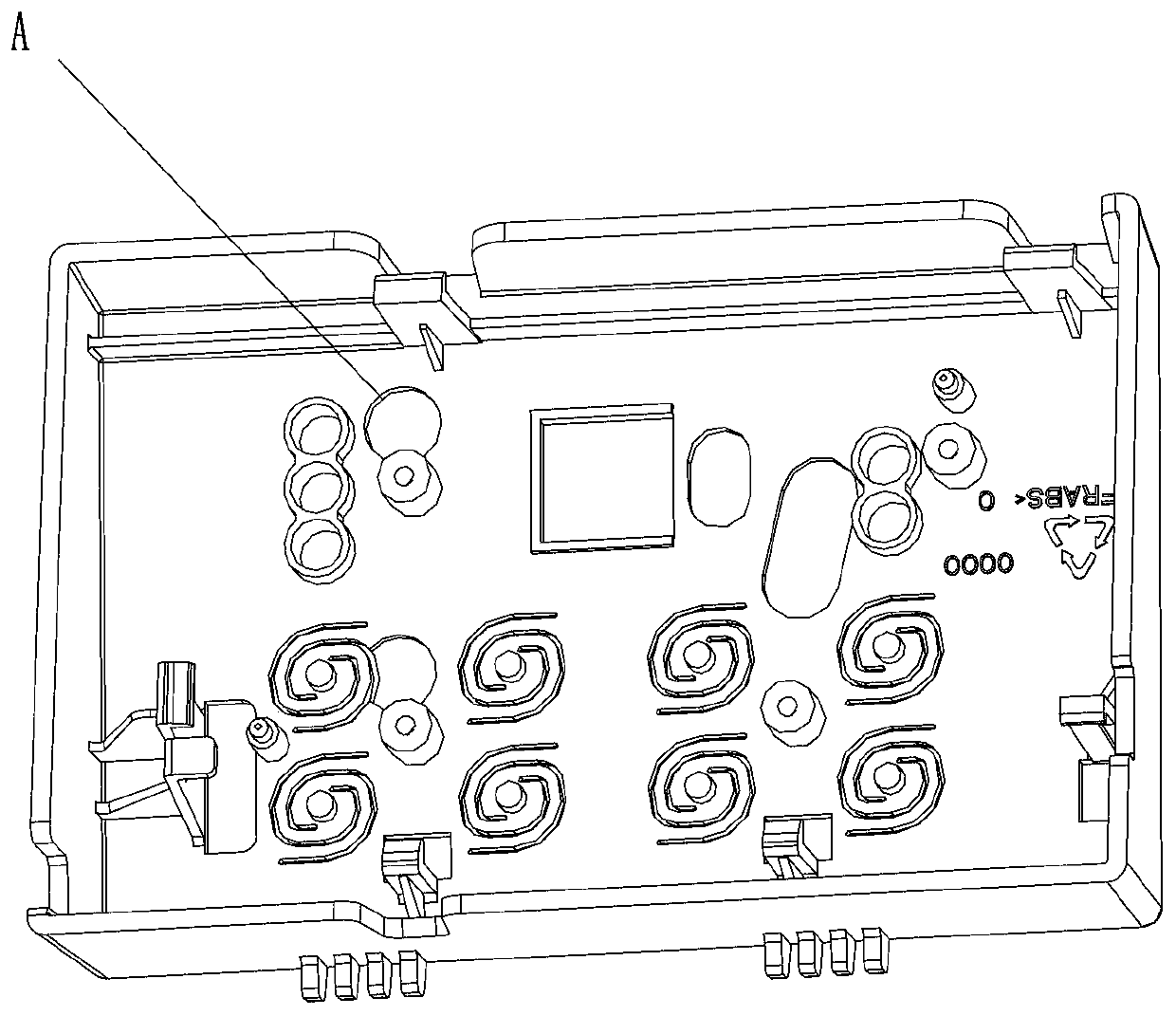

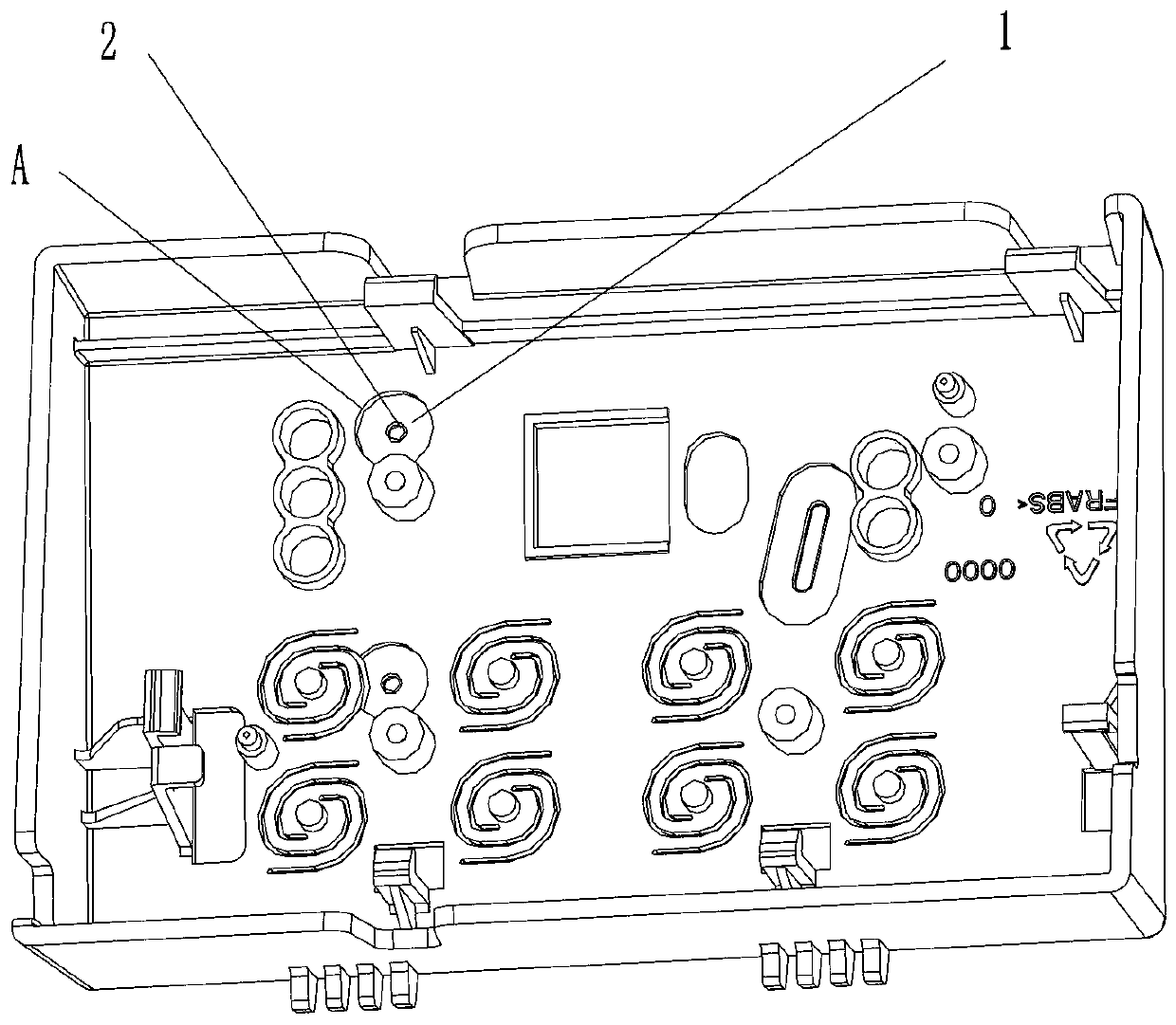

[0021] The embodiment of the present invention provides a kind of fixing plate of PCB board, such as figure 2 As shown, including the substrate, also includes the relief slot 1;

[0022] There are multiple relief grooves 1, which are respectively arranged at multiple relief positions of the substrate;

[0023] The step-off groove 1 is a groove that matches the appearance of the electrical components on the PCB that need to make way, and is used to accommodate the electrical components that need to make way on the PCB;

[0024] The bottom of the relief groove 1 is provided with a through hole 2 , and the cross-sectional area of the through hole 2 is smaller than that of the relief groove 1 .

[0025] The place where the substrate needs to make way, that is, the A region shown in the figure, and the make way groove 1 is arranged in the A region.

[0026] Preferably, as a possible implementation manner, the depth of the relief groove 1 is equal to the distance that the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com