Steam ironing bucket and steam ironing machine comprising same

A technology for ironing irons and ironing machines, which is applied to ironing machines, washing devices, textiles and papermaking, etc., can solve the problems of explosion of ironing equipment, inconvenient maintenance, threats to the safety of people's lives and properties, etc., and can prevent stress. Concentrate, ensure ironing quality, and solve the effect of bulging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

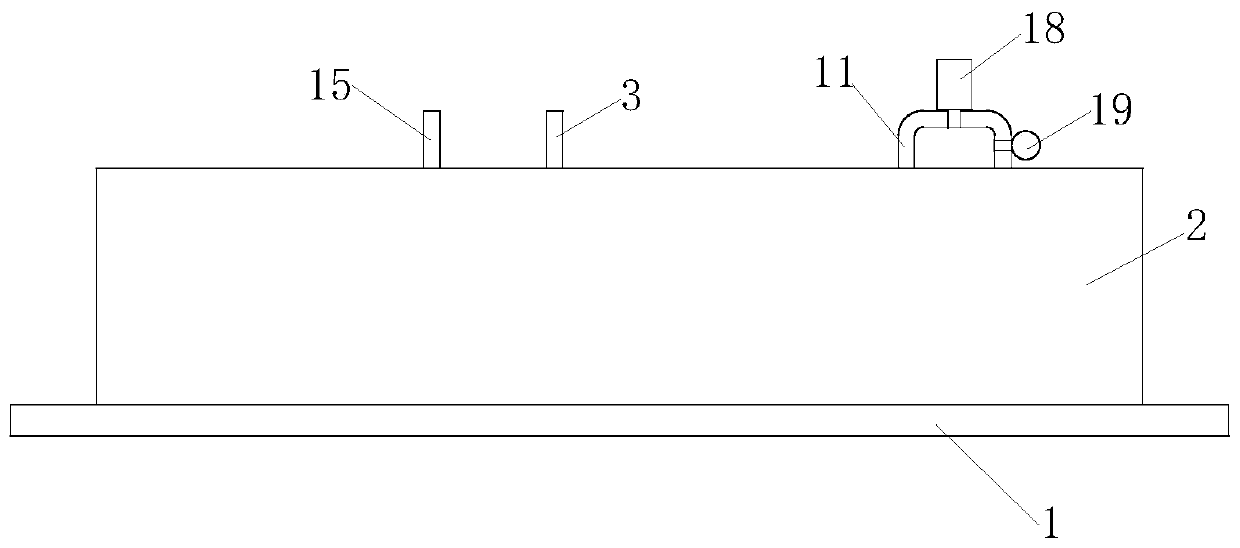

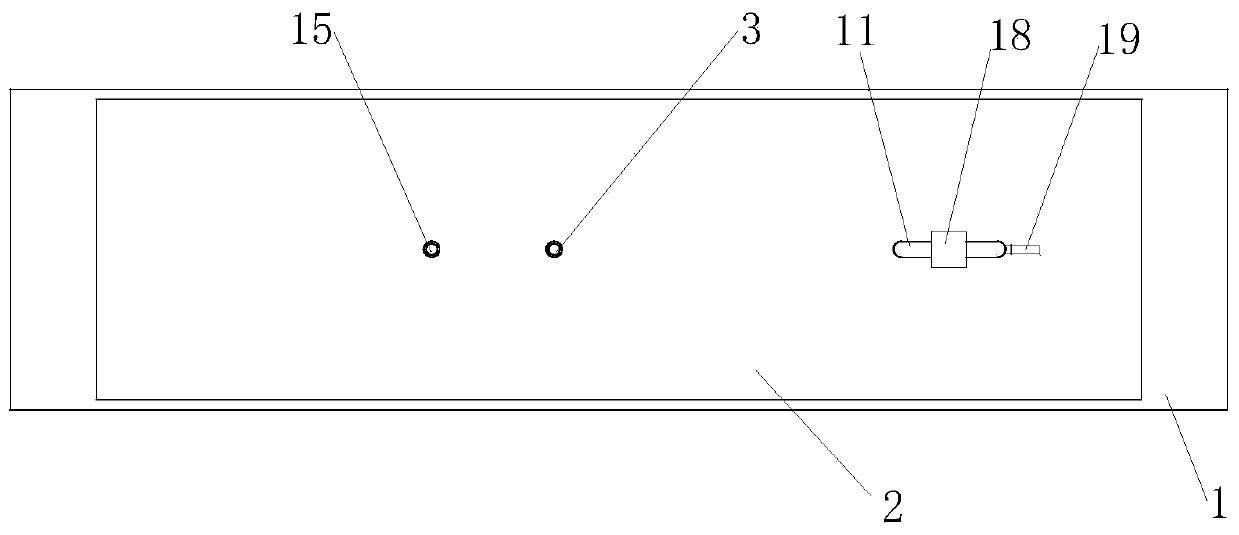

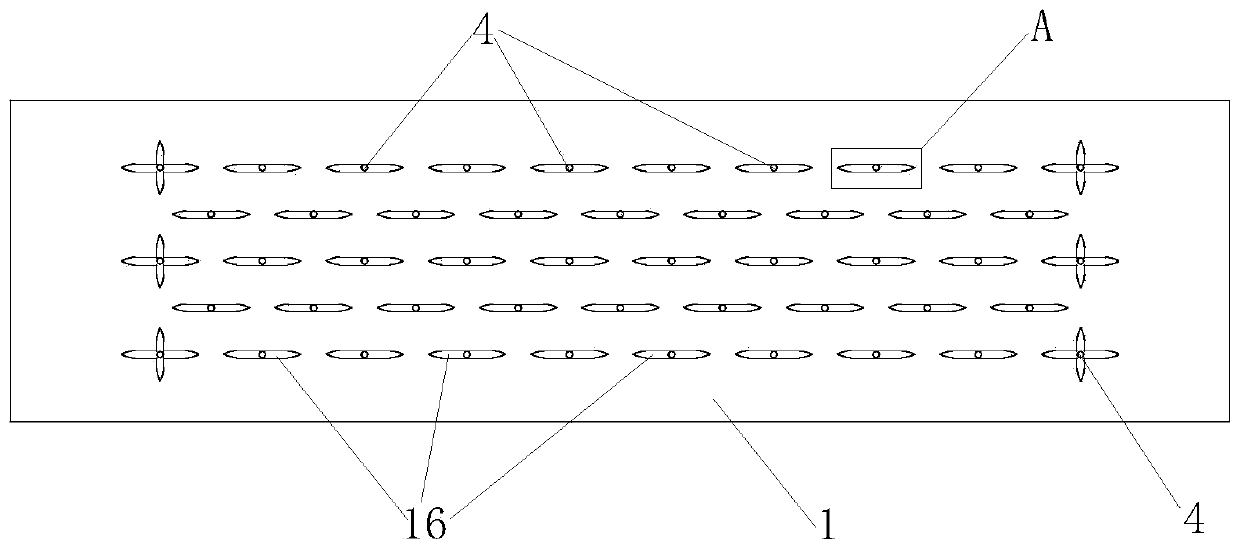

[0033] Depend on Figure 1 to Figure 8 As shown, the present invention provides a steam iron, which is provided with an ironing board 1 , an ironing cover 2 , a transverse partition 5 , a longitudinal partition 6 , a steam guide pipe, and a steam inlet pipe 3 . The ironing board 1 is provided with a steam injection hole 4, and the ironing cover 2 is sealed and connected with the ironing board 1, and the ironing cover 2 and the ironing board 1 enclose a steam chamber 36; usually, the ironing board 1 is arranged in a rectangular plate-like structure with a simple structure. The transverse partition 5 and the longitudinal partition 6 are arranged in the steam chamber 36 respectively, and the transverse partition 5 divides the steam chamber 36 into two sealed and isolated chambers, the steam collecting chamber 7 and the steam injection chamber 8 . The steam collecting chamber 7 is divided into a plurality of sub-steam collecting chambers 34 by the longitudinal partitions 6, and th...

Embodiment 2

[0040] On the basis of the technical scheme disclosed in embodiment 1, by Figure 13 As shown, the present invention also provides an intelligent control system, a steam solenoid valve 18, and a steam pressure sensor 19. The intelligent control system is provided with an intelligent control device 20, which can be a PLC controller, that is, a programmable logic controller. Steam solenoid valve 18 and steam pressure sensor 19 are respectively communicated and arranged on the steam guide pipe, wherein steam solenoid valve 18 is used to control the amount of steam in the steam guide pipe; steam pressure sensor 19 is used to sense the steam pressure in the steam guide pipe, and the steam The pressure is sent out through the control circuit in the form of an induction signal; usually, the steam solenoid valve 18 and the steam pressure sensor 19 are installed on the steam guiding main pipe 11 respectively. The intelligent control device 20 is electrically connected with the steam so...

Embodiment 3

[0043] On the basis of the technical solution disclosed in embodiment 1 or embodiment 2, the present invention also provides a steam ironing machine, the steam ironing machine can be an existing ironing equipment, and can be used for ironing cloth such as clothes, It can also be used for ironing bed sheets, quilt covers and other fabrics. For example, a steam ironing device claimed by publication number CN110592913A, the ironing and / or ironing tool of the steam ironing device can be replaced by a steam iron described in Embodiment 1 or Embodiment 2 of the present invention (according to the actual situation, what the steam iron of the present invention is made of is the same size as this patent ironing and / or ironing tool, for the convenience of hand-holding, a handle can be connected outside the ironing cover 2).

[0044] As a preference of this embodiment, by Figure 9-Figure 11 As shown, in order to save time and labor for ironing large pieces of cloth such as bed sheets a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com