Damping device for vibration attenuation of upper rollers and lower rollers of rolling mills

A technology of damping device and roller, which is applied in the direction of shock absorber, gas shock absorber, shock absorber, etc., can solve the problems that the effect of the roller is not very good, the damping force of the support rod changes greatly, and the roller cannot provide stable support force, etc. , to achieve the effect of less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

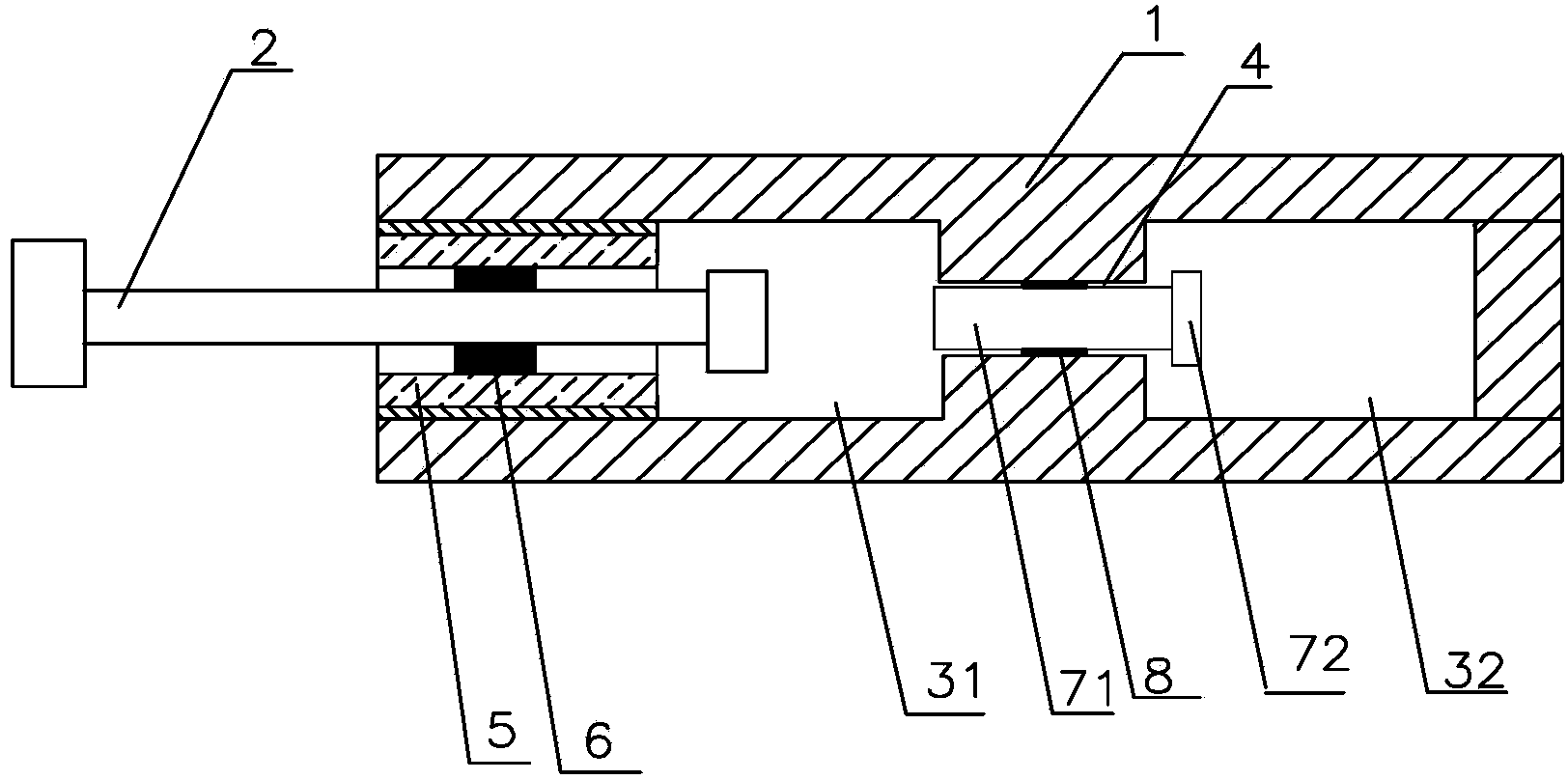

[0020] like figure 1 As shown, the damping device used in this embodiment to damp the vibration of the upper and lower rolls of the rolling mill includes a housing 1 with one end open, and two chambers are sequentially arranged in the housing, which are the first chamber 31 and the second chamber respectively. There are two chambers 32, and an air passage 4 is arranged between the first chamber and the second chamber.

[0021] The first chamber 31 communicates with the open end of the housing, and a support rod 2 is arranged in the first chamber along the center line of the first chamber, and the support rod extends to the outside of the housing. There is an airtight fit between the support rod and the first chamber.

[0022] A preferred airtight fit structure is as follows: a guide sealing ring 5 is sheathed on the outer periphery of the support rod, the guide seal ring and the inner wall of the first chamber are threaded, and the support rod and the inner wall of the first ...

Embodiment 2

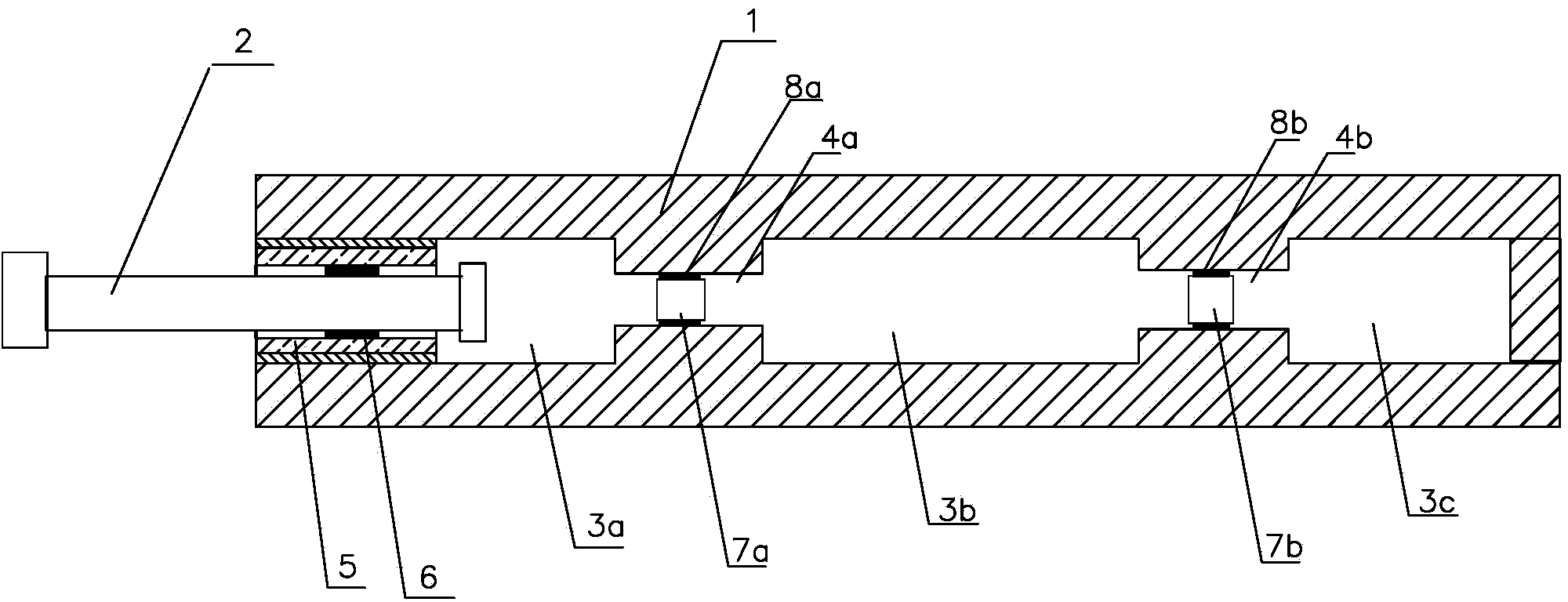

[0027] like figure 2 As shown, the damping device used in this embodiment to damp the vibration of the upper and lower rolls of the rolling mill includes a housing 1 with one end open, and three chambers are sequentially arranged in the housing, namely the first chamber 3a, the second chamber 3a, and the second chamber 3a. A chamber 3b and a third chamber 3c, a first air passage 4a is provided between the first chamber and the second chamber, a second chamber is provided between the second chamber and the third chamber Airway 4b.

[0028] The first chamber communicates with the opening end of the housing, and a support rod 2 is arranged in the first chamber along the direction of the center line of the first chamber, and the support rod extends to the outside of the housing. There is an airtight fit between the support rod and the first chamber.

[0029] A preferred airtight fit structure is as follows: a guide sealing ring 5 is sheathed on the outer periphery of the suppor...

Embodiment 3

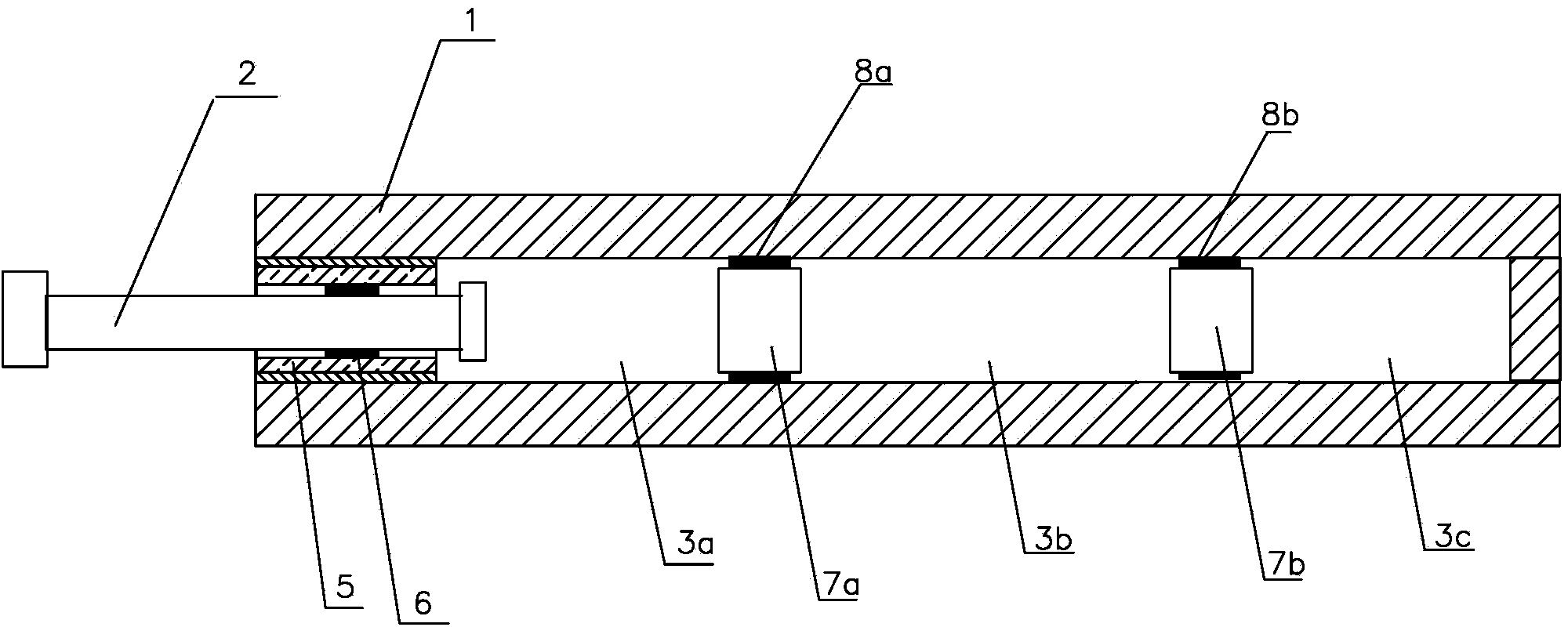

[0035] The difference between this embodiment and the above-mentioned embodiment 2 is only that the diameter of each air channel is equal to the diameter of each chamber.

[0036] The greater the number of chambers provided in the present invention, the more obvious the buffering effect of the other chambers on the first chamber, and the smoother the damping force produced by the first chamber on the support rods, thus providing the upper and lower rolls Provides more stable support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com