Hydraulic tensioner

A tensioner and hydraulic technology, applied to belts/chains/gears, mechanical equipment, transmissions, etc., can solve problems such as increased engine energy consumption, chain vibration, and impact on vehicle NVH performance, achieving easy layout and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

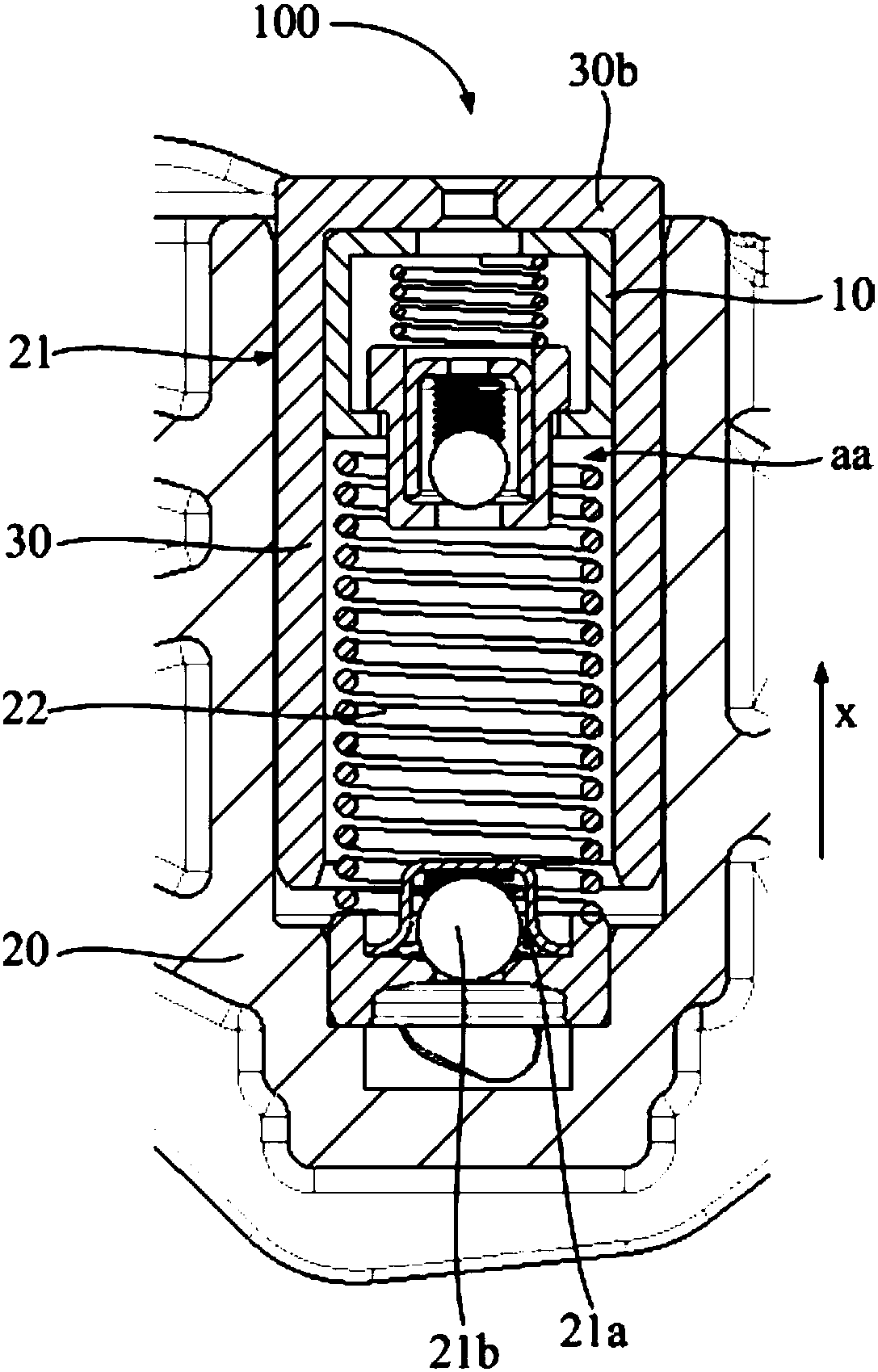

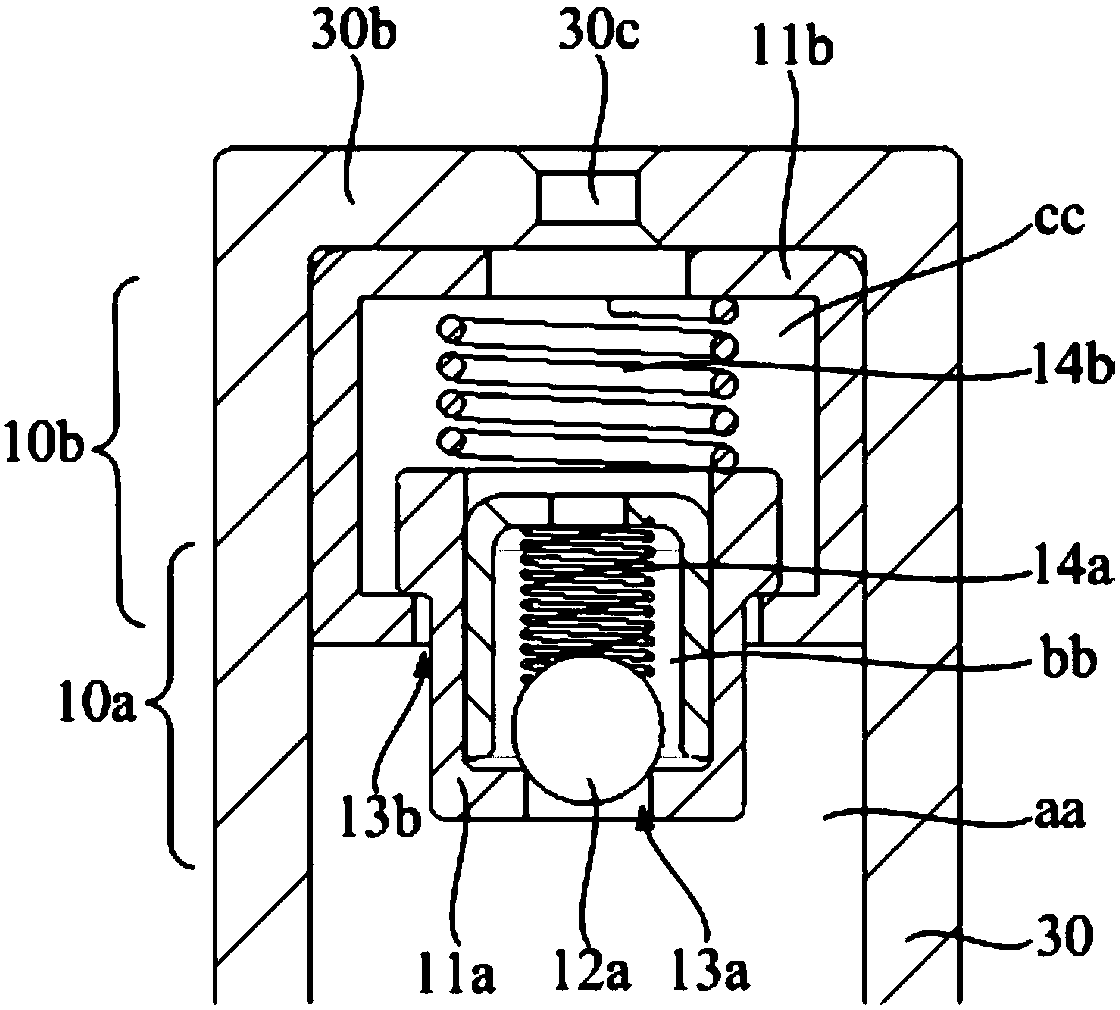

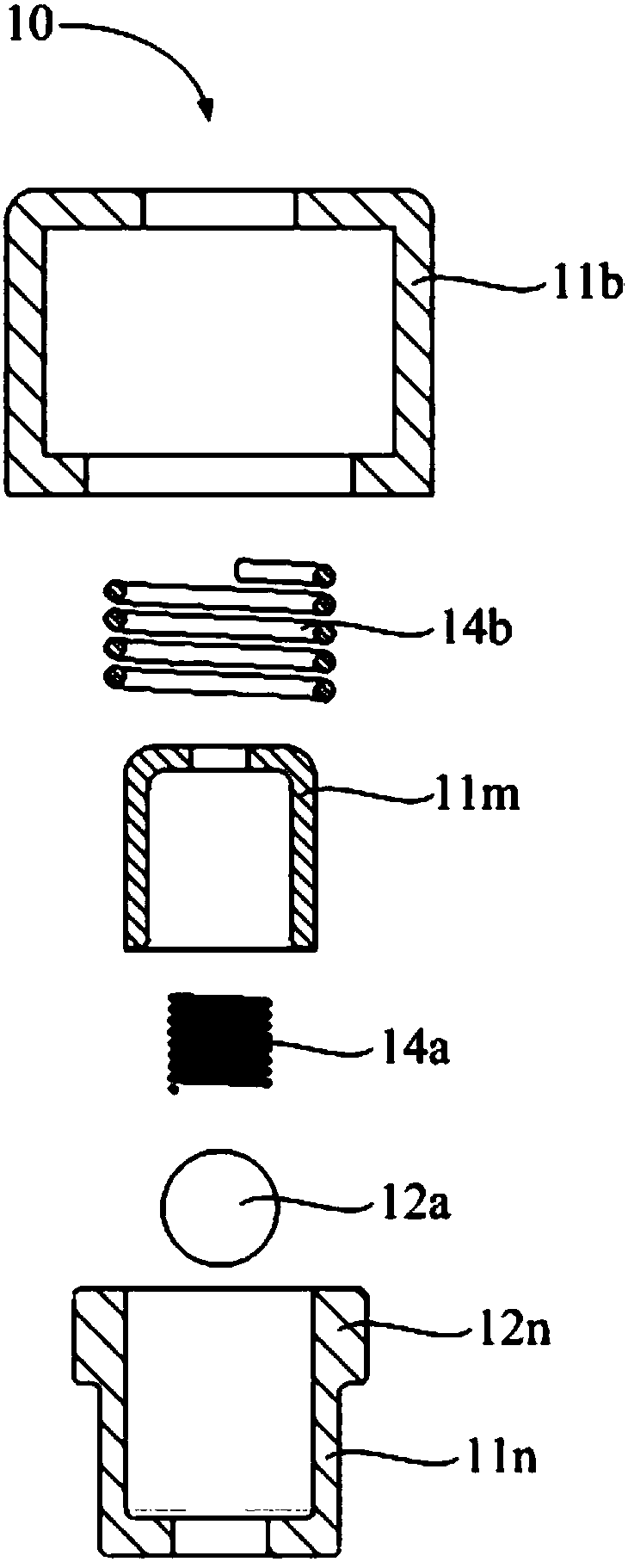

[0034] refer to figure 1 , a hydraulic tensioner 100, comprising a tensioner housing 20 and a plunger 30. Wherein, the tensioner housing 20 has a damping hole 21, and the bottom of the damping hole 21 is provided with a liquid inlet hole 21a, and the pressure medium (such as hydraulic oil, etc.) can enter the damping hole 21 through the liquid inlet hole 21a; The plug 30 is arranged in the damping hole 21, the inside of the plunger 30 forms a pressure chamber aa, the pressure chamber aa runs through the bottom of the plunger 30 to communicate with the damping hole 21, and the top of the plunger 30 protrudes to the damping hole 21 In addition, it is used to offset the conveyor chain or conveyor belt of the engine.

[0035] The first coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com