Hydraulic shock-absorbing device for tamping coal charging car

A technology for hydraulic vibration reduction and coal loading vehicles, which is applied in the direction of material forming presses, presses, manufacturing tools, etc. It can solve the problems of difficult disassembly, limited space, poor vibration reduction effect, etc., and achieve good vibration reduction effect, Easy maintenance and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

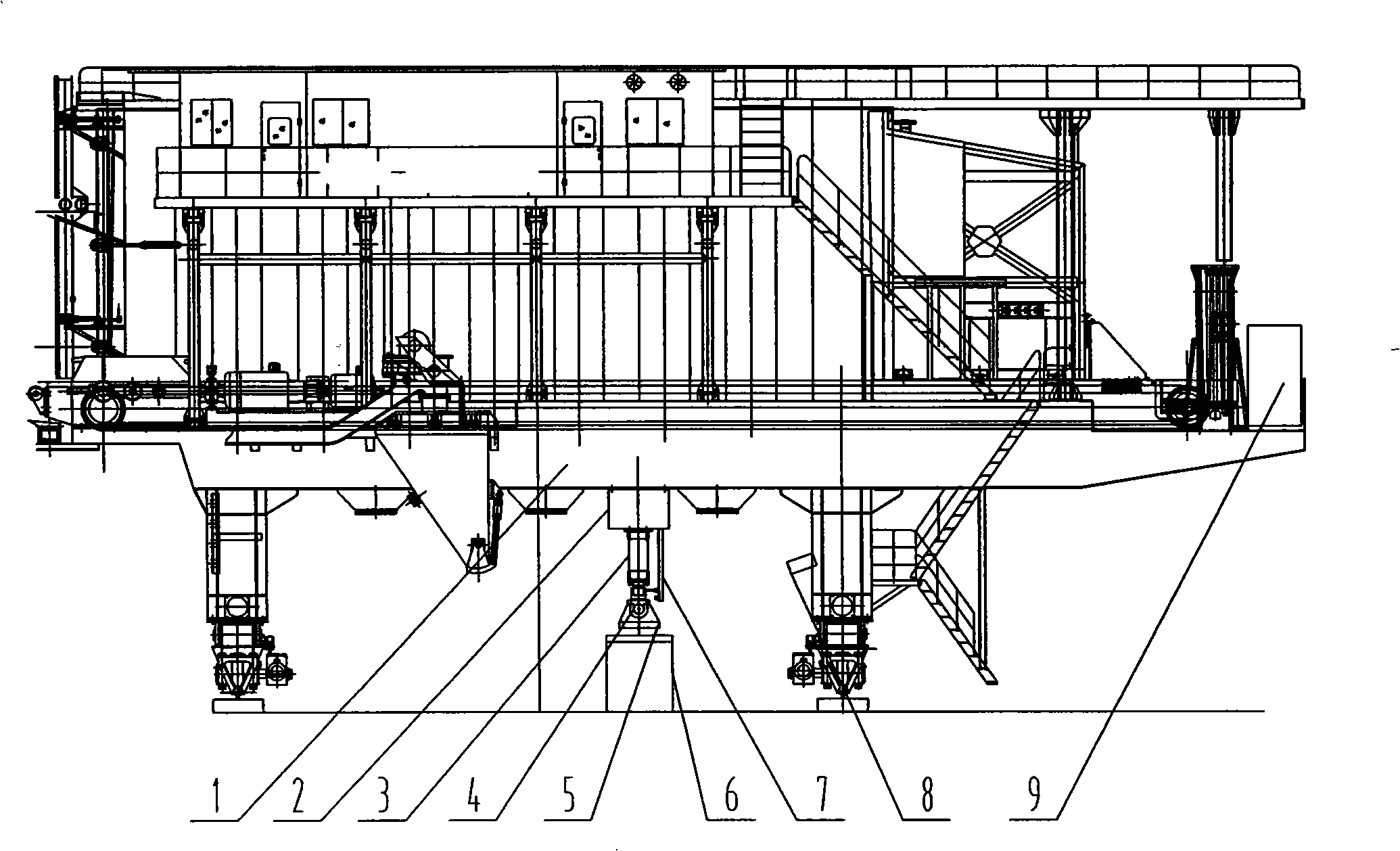

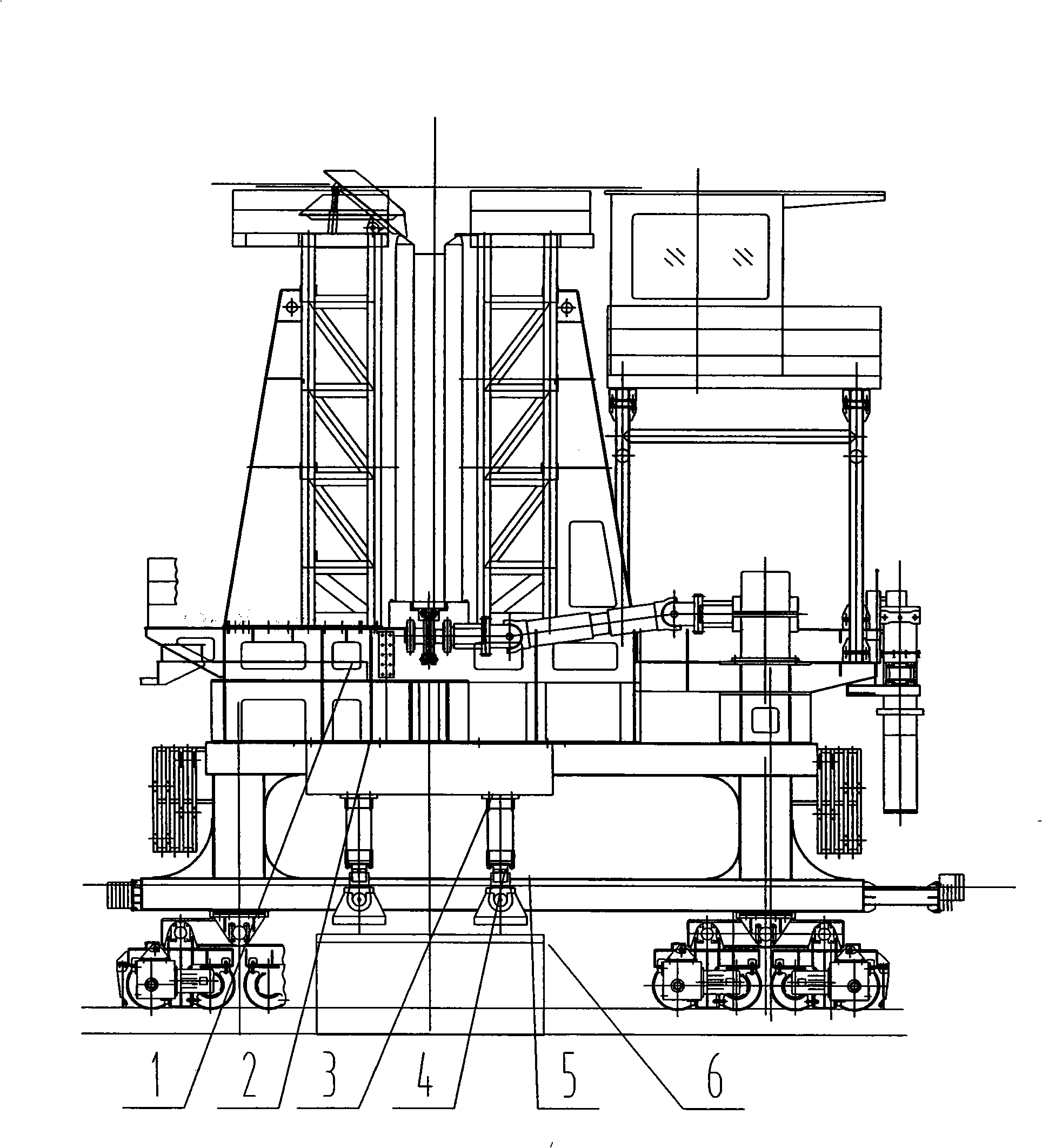

[0012] Such as figure 1 , 2 As shown, a hydraulic damping device for a tamping coal-charging car is installed with a support beam 2 at the bottom of the car body 1 between the running tracks of the tamping coal-loading car, and at least two are connected to the support beam 2 along the running direction. Hydraulic cylinder 3 (the present embodiment is two hydraulic cylinders), hydraulic cylinder 3 is powered by the hydraulic system 9 installed on the car body 1, hydraulic cylinder 3 is connected with support shoe 5 through joint bearing 4, corresponds to support shoe 5 in Support seat 6 is installed on the civil foundation below it. The joint bearing 4 can adjust the parallelism between the supporting surfaces.

[0013] In order to confirm that the support shoe 5 contacts or separates from the support seat 6 , a limit device 7 is installed between the hydraulic cylinder 3 and the support beam 2 .

[0014] In order to ensure safety, a camera 8 is installed at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com