Temperature test chamber calibration and point distribution device

A temperature test and fixture device technology, applied in thermometer testing/calibration, thermometers, measuring devices, etc., can solve the problems of large sensor damage, inaccurate position, and low efficiency, and achieve easy operation, wide measurement range, and high efficiency of point layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

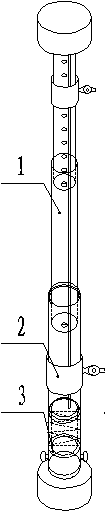

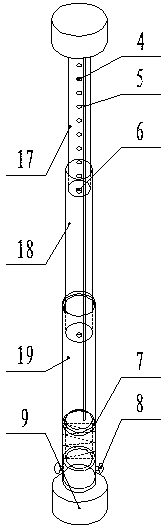

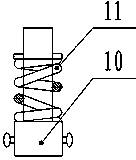

[0020] Such as Figure 1~Figure 5 As shown, the temperature test chamber calibration arrangement device includes a telescopic rod device 1 and a clamp device 3, the bottom end of the telescopic rod device 1 is provided with a pressing device 2, the telescopic rod device 1 is rod-shaped, and the clamp device 3 is detachable Connected to the telescopic rod device 1, using the telescopic telescopic rod device 1, the pressing device 2 and the detachable fixture device 3, only need to measure the size of the temperature test chamber, calculate the distance, and adjust the fixture according to the calculated distance and the position of the telescopic rod, start the compression device 2 to compress the telescopic rod, and finally clamp the temperature sensor with a clamp, so that the sensor can be placed accurately, with high efficiency, the sensor is not easily damaged, and the operation is simple.

[0021] The telescopic rod device 1 includes three stainless steel metal hollow umb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com