An integrated device for ink supply and cleaning of nozzles

An ink supply and nozzle technology, which is applied to the field of an integrated device for ink supply and cleaning of the nozzle, can solve the problems of time-consuming and laborious, troublesome nozzle cleaning, poor cleaning effect, etc., and achieves the effect of easy operation, simple and convenient cleaning, and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

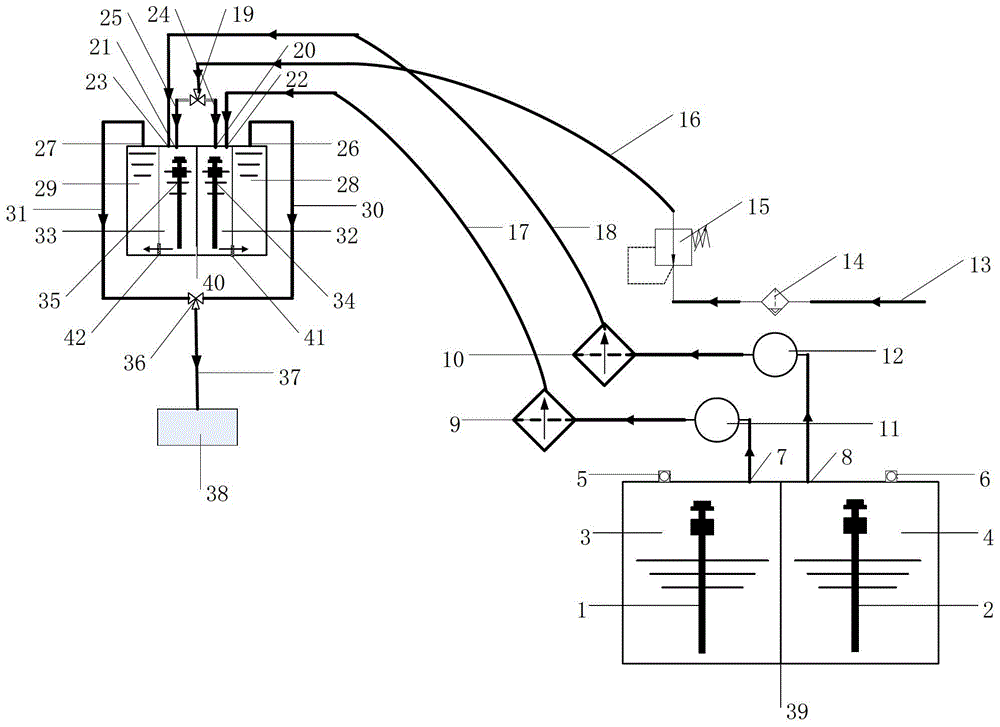

[0024] This embodiment provides an ink supply and cleaning device for a nozzle, including an ink supply unit for supplying ink to the nozzle, a liquid supply unit for providing cleaning liquid to the nozzle, and a gating unit, one end of the gating unit is connected to the The nozzle is in communication, and the other end of the nozzle can selectively communicate with the ink supply unit or the liquid supply unit.

Embodiment 2

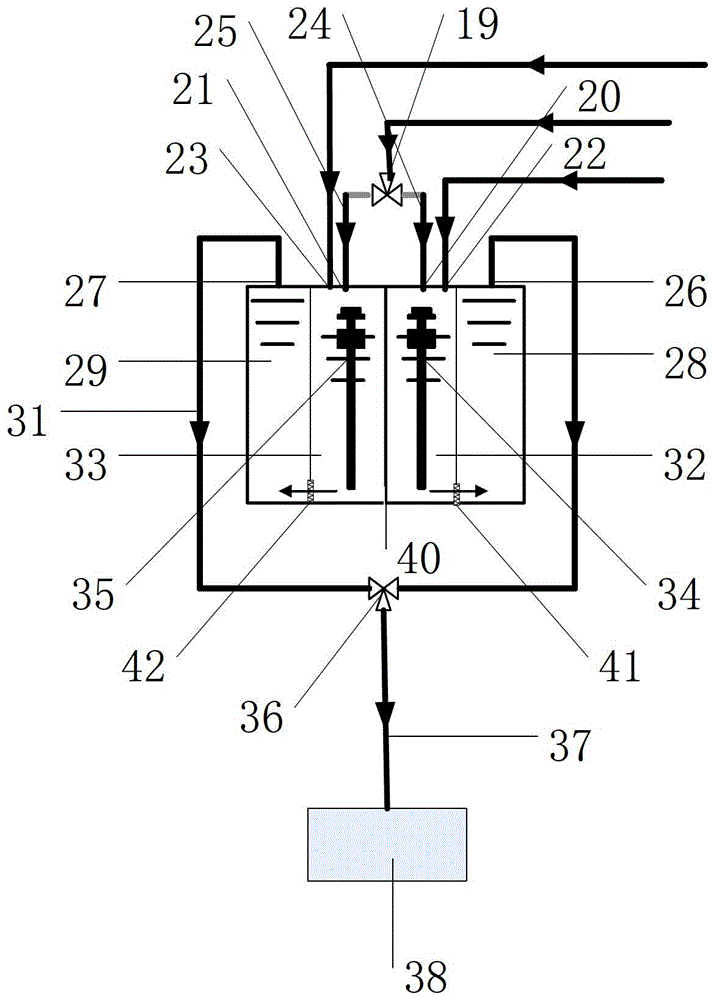

[0026] Such as figure 1 As shown, in this embodiment, the nozzle ink supply and cleaning device includes an ink supply unit for providing ink to the nozzle 38, a liquid supply unit for providing cleaning liquid to the nozzle 38, and a gating unit, the gating One end of the unit communicates with the spray head 38, and the other end can selectively communicate with the ink supply unit or the liquid supply unit.

[0027] In this embodiment, the ink supply unit includes an ink supply chamber, an ink storage chamber 4 and a first drive mechanism, wherein the ink supply chamber is connected to the gating unit; the ink storage chamber 4 is connected to the ink supply chamber communicated for storing ink; the first driving mechanism is used for delivering the ink in the ink storage chamber 4 to the ink supply chamber. The liquid supply unit includes a liquid supply chamber, a liquid storage chamber 3 and a second drive mechanism, the liquid supply chamber is connected to the gating ...

Embodiment 3

[0046] The difference between the nozzle ink supply and cleaning device in this embodiment and Embodiment 2 is that in this embodiment, the ink supply unit does not have a first alarm mechanism, and the liquid supply unit does not have a second alarm mechanism.

[0047] In this embodiment, the ink storage chamber 4 and the liquid storage chamber 3 are respectively provided with observation windows, and the operator can check the liquid level height of the ink in the ink storage chamber 4 and the liquid level of the cleaning liquid in the liquid storage chamber 3 through the observation windows. high.

[0048] Other structures of the nozzle ink supply and cleaning device in this embodiment are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com