A feeding device for fully automatic steel office furniture sheet punching and shearing machine

A feeding device, fully automatic technology, applied in the direction of feeding device, manufacturing tool, positioning device, etc., can solve the problems of increased production cost, and achieve the effect of accurate delivery position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

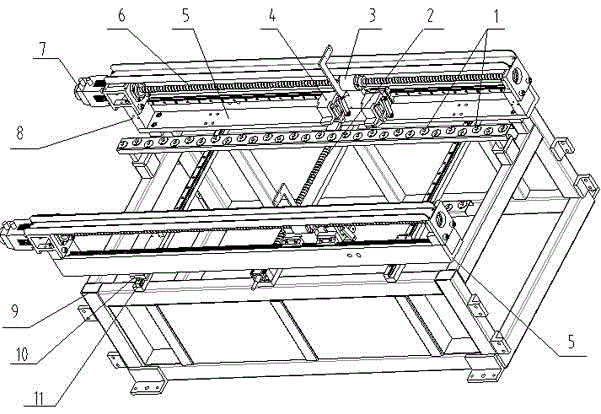

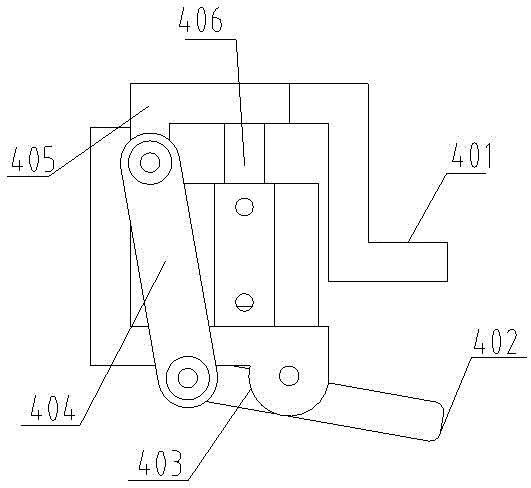

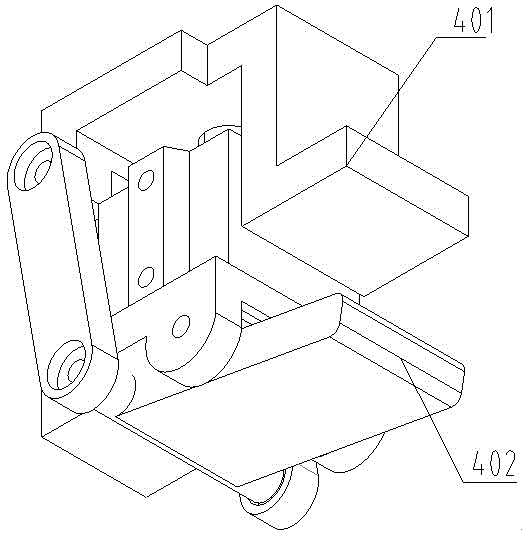

[0019] As shown in the figure, a feeding device for a fully automatic steel office furniture sheet metal punching and shearing machine includes a feeding base 9, and a set of feeding mechanisms are respectively provided on both sides of the feeding base 9 in a direction perpendicular to the feeding direction. A plate conveying channel is formed between two sets of feeding mechanisms, and the feeding mechanism includes a feeding screw 6, and the feeding screw 6 is arranged on the feeding mechanism support plate 5 along the feeding direction through the feeding screw support seat 8, and the feeding mechanism It also includes two grippers 4 connected to the feed screw 6 through the feed slider 3, and a feed servo motor 7 connected to the feed screw 6. The two sets of feed mechanisms are used separately, thereby forming a cyclic relay to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com