Diesel engine piston blank conveying equipment

A diesel engine and conveying equipment technology, which is applied in metal processing equipment, operating devices, manufacturing tools, etc., can solve the problems of easy falling of the piston, damage to the surface of the piston due to collision, and low conveying efficiency, so as to improve the conveying efficiency and stabilize the conveying process Reliable, delivered position-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

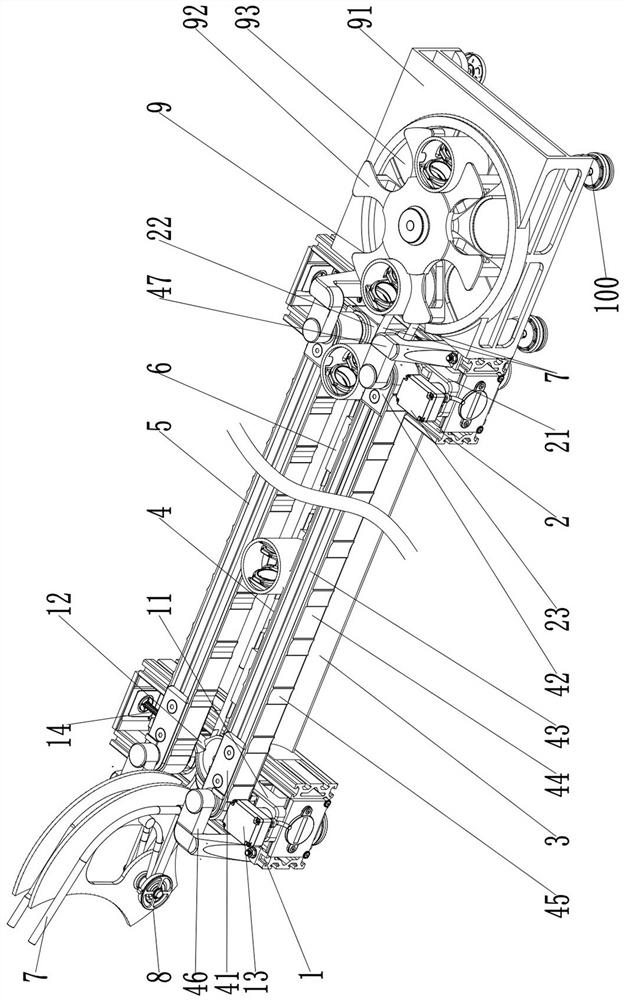

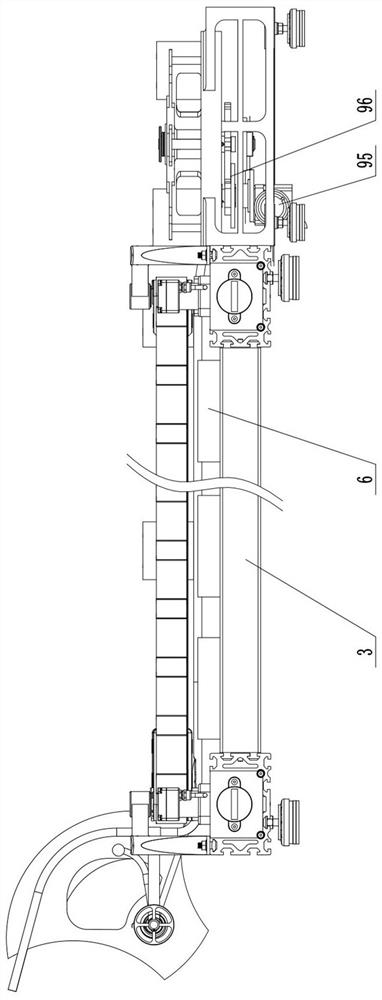

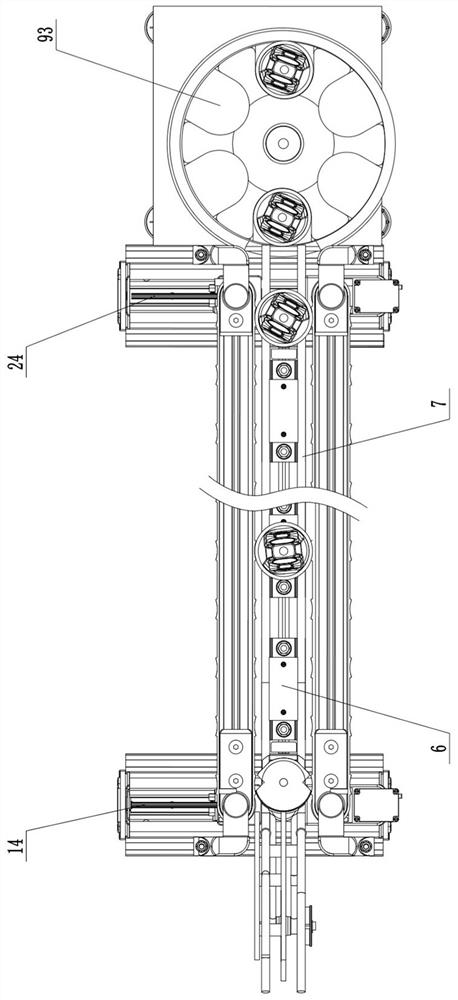

[0029] combined with Figure 1-10 , a diesel engine piston blank conveying equipment, comprising a front support base 1, a rear support base 2, a support beam 3, the two ends of the support beam 3 are respectively fixedly connected to the front support base 1 and the rear support base 2, the front Mounting seat one 11 and mounting seat two 12 are respectively arranged in the supporting seat 1, a front servo motor 13 is set on the said mounting seat one 11, a synchronous rotating shaft one 14 is set for rotation in the said front supporting seat 1, and a synchronous rotating shaft one 14 is arranged in the said rear supporting seat 2. Mounting seat 3 21 and mounting seat 4 22 are arranged respectively, a rear servo motor 23 is set on the mounting seat 3 21, a synchronous rotating shaft 2 24 is set for rotation in the rear supporting seat 2, and the mounting seat 1 11 and mounting seat 3 21 The conveying device one 4 is installed on the top, the conveying device two 5 is install...

Embodiment 2

[0038] When the device is in use, the manipulator puts the roughly processed piston blank onto the conduit group 7, and the input device is slowly placed between the conveying device one 4 and the conveying device two 5, and the supporting plate 87 drops onto the conduit group 7 each time. , the control device will automatically control the front servo motor 13 and the rear servo motor 23 to run a certain stroke at the same time to transport the piston blank forward one unit in turn, and the piston blank will automatically fall into the piston card of the unloading table 91 after being transported to the end of the catheter group 7 In the port 93, the control device controls the rotary drive motor 95 to drive the chuck 92 to rotate and push the piston.

Embodiment 3

[0040] Another specific way of using this equipment: install an oil nozzle on the fixed seat 6, pre-spray oil for the piston that is about to be stamped, and install a corresponding oil recovery device at the bottom of the support beam 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com