An automatic conveying mechanism for machining equipment

An automatic conveying and machining technology, which is applied in metal processing and other directions, can solve the problems affecting material conveying and processing, the conveying position is not easy to control, and cannot meet the requirements of rapid production, etc., to achieve the effect of improving production efficiency, rich functions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

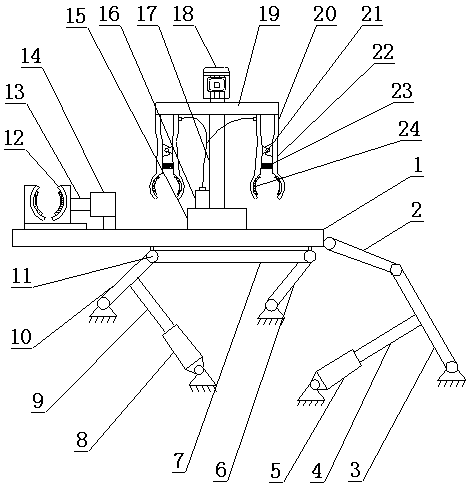

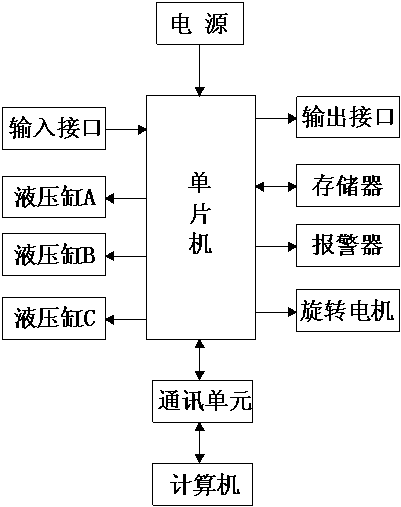

[0016] Such as figure 1 and figure 2 Shown, a kind of automatic conveying mechanism of machining equipment, it comprises transmission plate 1 and single-chip microcomputer, described transmission plate 1 is connected with connecting rod A2, and described connecting rod A2 is connected with fork A3, and described fork A3 is connected with a piston rod A4 and a hydraulic cylinder A5, and the bottom of the transmission plate 1 is equipped with a roller 11, and the roller 11 is connected with a connecting rod B7, and the connecting rod B7 is connected with a swing rod B6 and a swing rod C10 , the swing rod C10 is connected with a piston rod B9 and a hydraulic cylinder B8, the upper part of the transmission plate 1 is equipped with a clamping device 12 and a support seat 15, and the clamping device 12 is connected with a piston rod 13C and hydraulic pressure Cylinder C14, the upper end of the support seat 15 is equipped with a cylinder 16 and a support frame 17, the top of the su...

Embodiment 2

[0019] Such as figure 1 and figure 2 Shown, a kind of automatic conveying mechanism of machining equipment, it comprises transmission plate 1 and single-chip microcomputer, described transmission plate 1 is connected with connecting rod A2, and described connecting rod A2 is connected with fork A3, and described fork A3 is connected with a piston rod A4 and a hydraulic cylinder A5, and the bottom of the transmission plate 1 is equipped with a roller 11, and the roller 11 is connected with a connecting rod B7, and the connecting rod B7 is connected with a swing rod B6 and a swing rod C10 , the swing rod C10 is connected with a piston rod B9 and a hydraulic cylinder B8, the upper part of the transmission plate 1 is equipped with a clamping device 12 and a support seat 15, and the clamping device 12 is connected with a piston rod 13C and hydraulic pressure Cylinder C14, the upper end of the support seat 15 is equipped with a cylinder 16 and a support frame 17, the top of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com