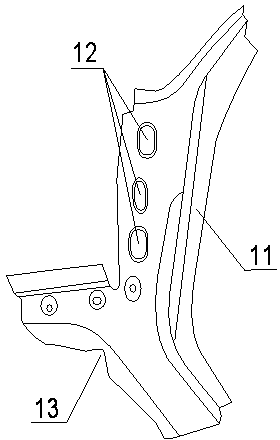

Automobile rear column plate assembly storing and transferring device

A technology of rear pillar plate and assembly, which is applied in the field of automobile sheet metal parts storage device, can solve the problems of poor movement stability, inconvenient movement of the rear pillar plate assembly, and easily damaged parts, etc., and achieves convenient storage and good storage stability. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

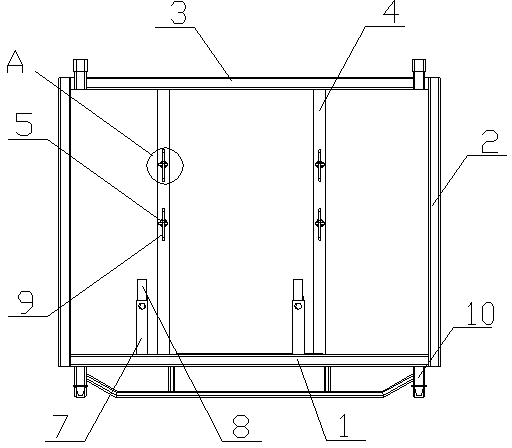

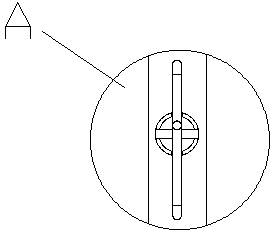

[0025] Example: see figure 1 , a storage and transfer device for the rear pillar plate assembly of an automobile, comprising a rectangular support chassis 1, four pillars 2 are vertically arranged on the support chassis 1, and the four pillars 2 are respectively located at the four corners of the support chassis 1. Between the two uprights 2 at both ends of the supporting chassis 1 and between the two uprights 2 on one side of the supporting chassis 1 are respectively provided with a connecting rod 3, the connecting rod 3 is fixedly connected with the upper end of the upright 2, so that a support is formed above the supporting chassis 1 Frame with open sides; through this open side, the rear pillar panel can be put in and out more conveniently, thus improving access efficiency.

[0026] At least one vertical bar 4 is arranged between the connecting rod 3 on one side of the supporting chassis 1 and the supporting chassis 1, the upper end of the vertical bar 4 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com