Openhole Anchor Flushing Hand Dropper and Its Application in Well Completion Construction

An open-hole, construction technology, applied in wellbore/well components, earthwork drilling and other directions, can solve problems such as unsmooth construction, rework, wellbore scrapped, etc., and achieve unique design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

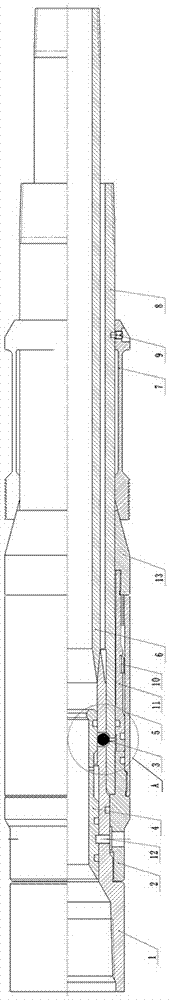

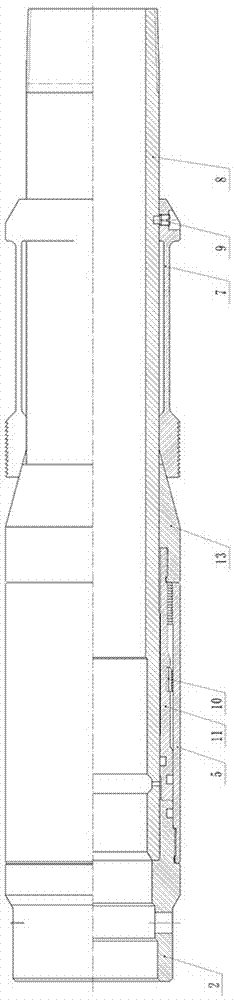

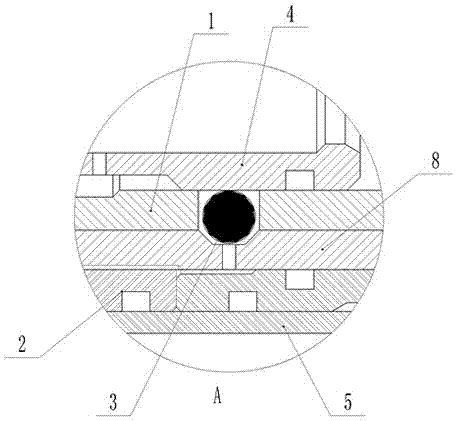

[0018] Such as figure 1 Said, open-eye anchor flush-style hand drop, including top joint. The outer wall of the lower end of the upper joint is provided with a torque head, and the upper joint is provided with an inner sliding sleeve. The torque head, upper joint, and inner sliding sleeve are fixed together by shear nails. The flushing pipe, the inner flushing pipe is located in the screen pipe. The lower part of the upper joint is provided with a through hole on the wall between the inner sliding sleeve and the screen pipe, and a ball is arranged in the through hole, and the space where the ball is located narrows toward the direction of the screen pipe. There is a ring groove on the outer wall of the inner sliding sleeve corresponding to the ball. The ring groove is provided with a through hole connecting the inner and outer spaces of the inner sliding sleeve. The lower end of the inner sliding sleeve is provided with an inner convex ring. The pipe wall is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com