Bearing seat balance structure

A technology of balancing structure and bearing seat, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of wear, large load on one side of the bearing seat, and uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

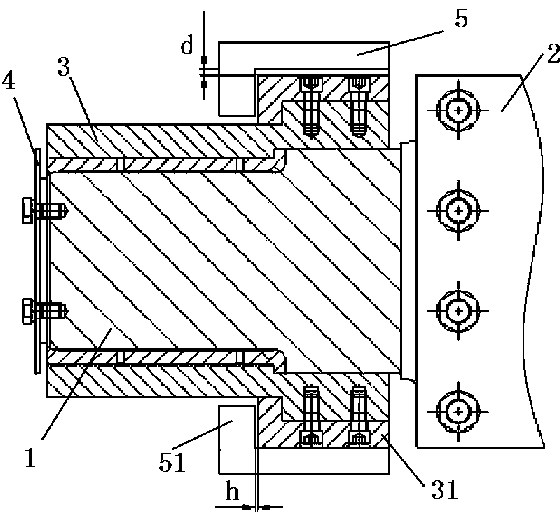

[0010] Such as figure 1 As shown, in the bearing housing balance structure of the present invention, the rotating shaft 1 connected in rotation in the bearing housing 2, and the rotating shaft 1 protrudes from the bearing housing 2 to form a balancing section. A balance sleeve 3 is keyed on the balance section, and an end panel 4 that axially restricts the balance sleeve from coming out is fixed on the end surface of the balance section by screws. The section of the balancing section is stepped, and the inner wall of the balancing sleeve 3 matches the stepped section of the balancing section. The above arrangement can play the role of axially restricting the movement of the balance sleeve 3 . The radial direction of the balance sleeve 3 is provided with a balance sleeve base 5 supporting the balance section, the balance sleeve base 5 includes an inwardly extending annular boss 51, and the annular boss 51 is located between the balance sleeve 3 and the end panel 4 Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com