Automobile synchronizer with front and back inverted conical surfaces

A technology of synchronizer and conical surface, which is applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc. It can solve the problems of unstable transmission of gearboxes, unreliable gear shifting, and high operating noise, so as to improve the reliability of shifting gears and make it difficult The effects of gear drop and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

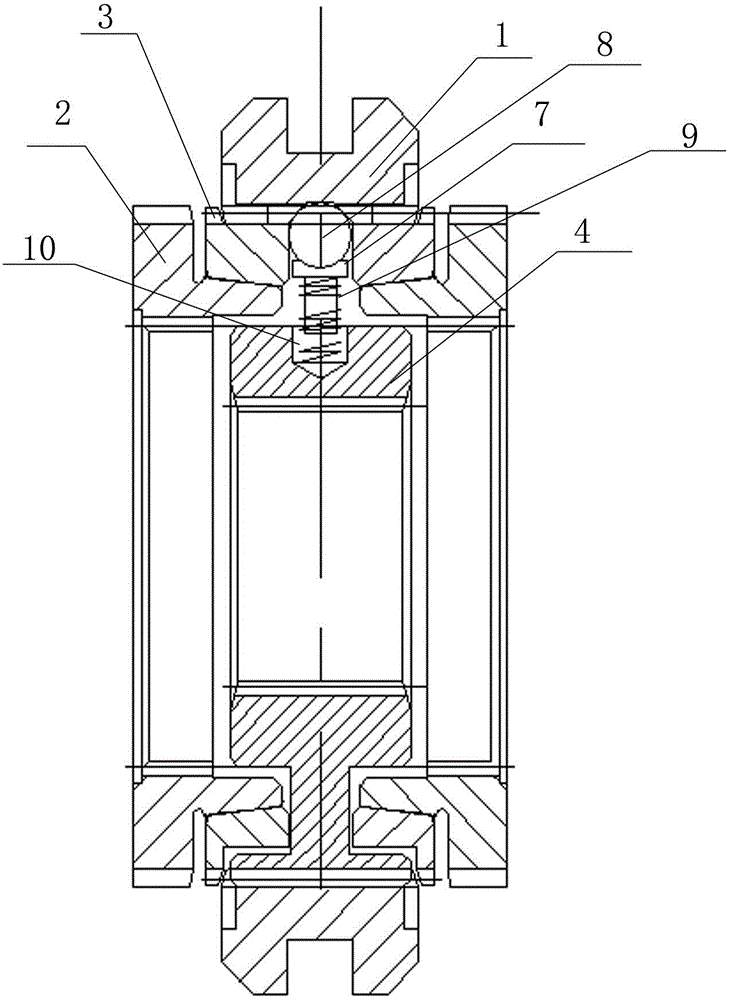

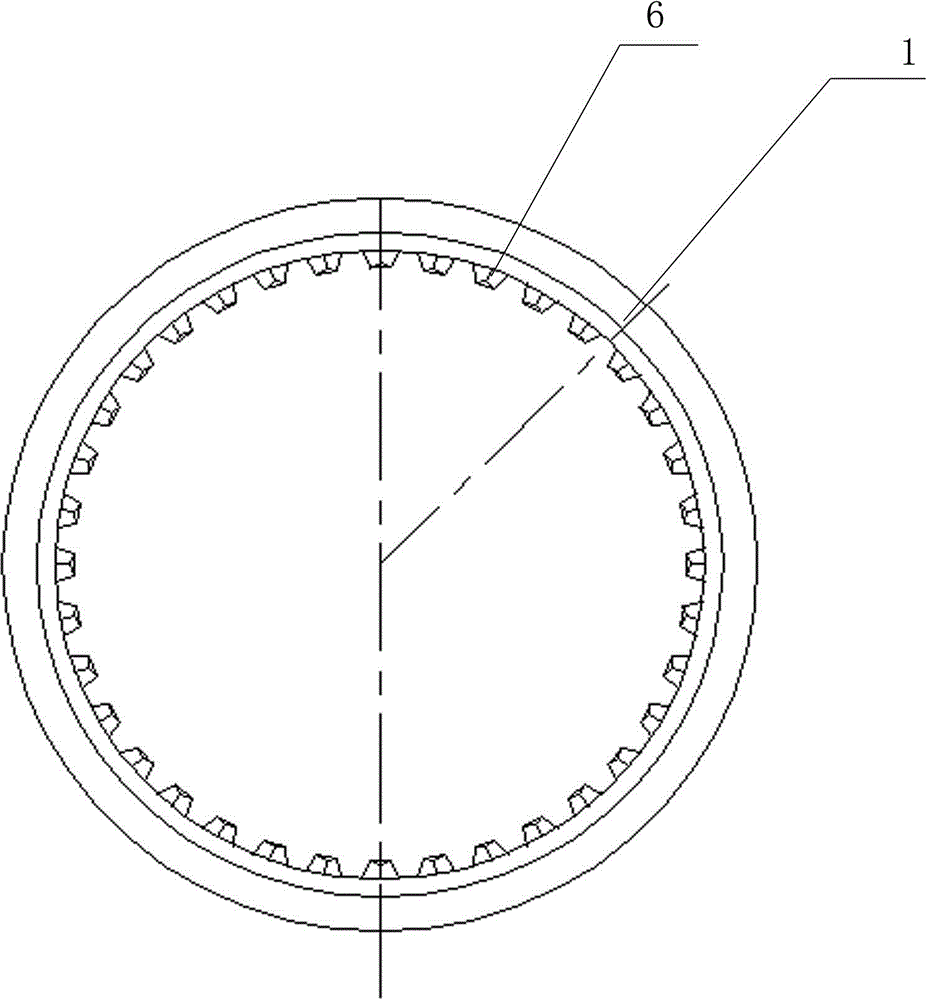

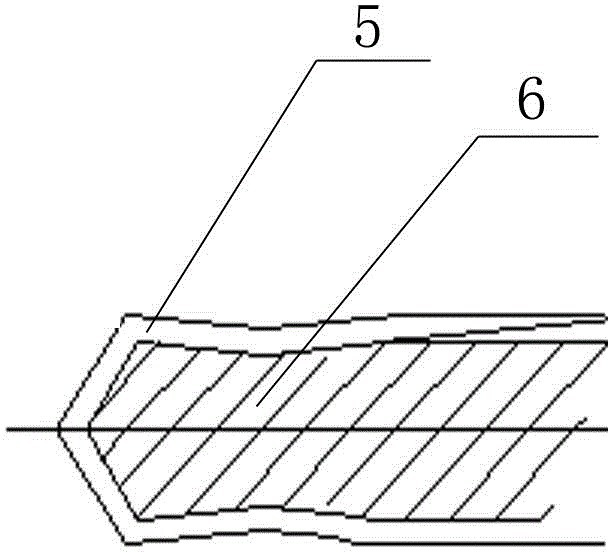

[0010] exist figure 1 , figure 2 and image 3 Among them, the present invention provides a kind of positive and negative reverse cone automotive synchronizer, which includes a synchronous sliding sleeve 1, two synchronous cone hubs 2, two synchronous gear rings 3 and a synchronous tooth seat 4, and the synchronous sliding sleeve 1 is set on the synchronous tooth seat 4 There is a support assembly between a part of the synchronous tooth seat 4 and the synchronous sliding sleeve 1, and the rest of the synchronous tooth seat 4 is connected with the synchronous sliding sleeve 1 through a spline combination, and the synchronous sliding sleeve 1 is connected with the synchronous The tooth seat 4 rotates together, and the synchronous sliding sleeve 1 moves left and right along the axial direction on the synchronous tooth seat 4 when shifting gears. The two synchronous tooth rings 3 are pressed on the two surfaces of the synchronous tooth seat 4. There are two synchronous conical h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com