Driving device for microfluidic micro valve

A driving device and microfluidic technology, applied in valve devices, valve operation/release devices, valve details, etc., can solve the problems of hidden reliability, chip failure, easy leakage of micro-membrane pumps, etc., to improve reliability and facilitate the Parallel drive, the effect of reducing the chance of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

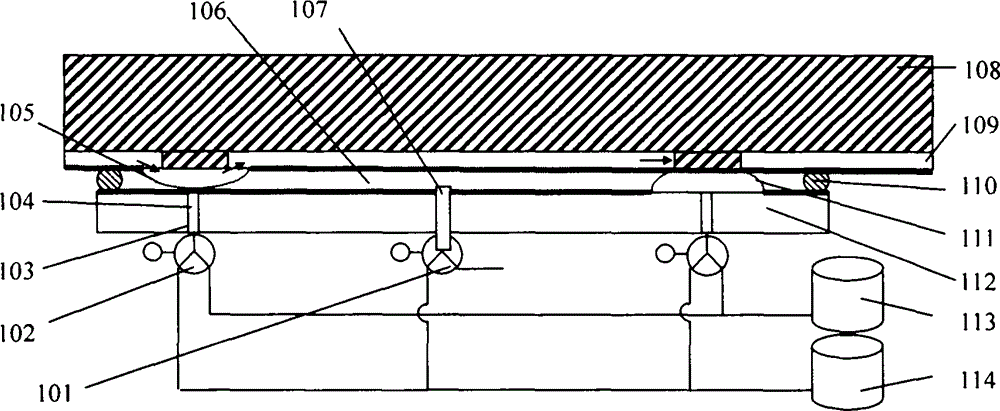

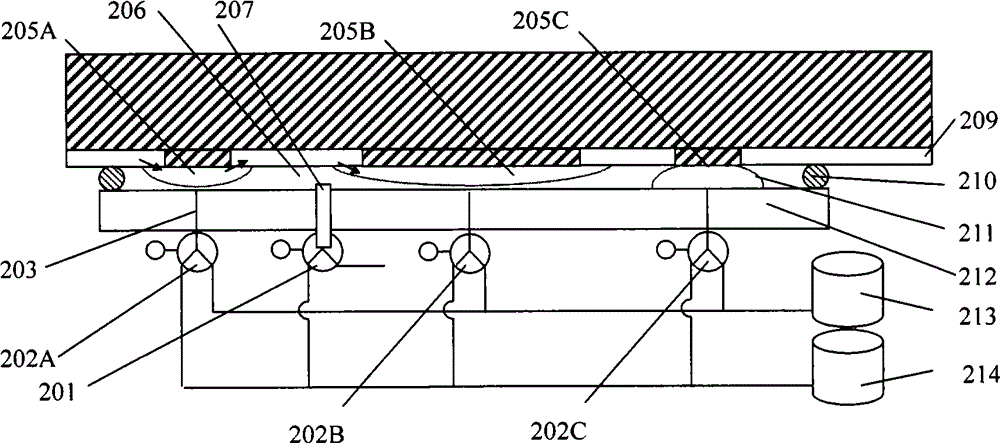

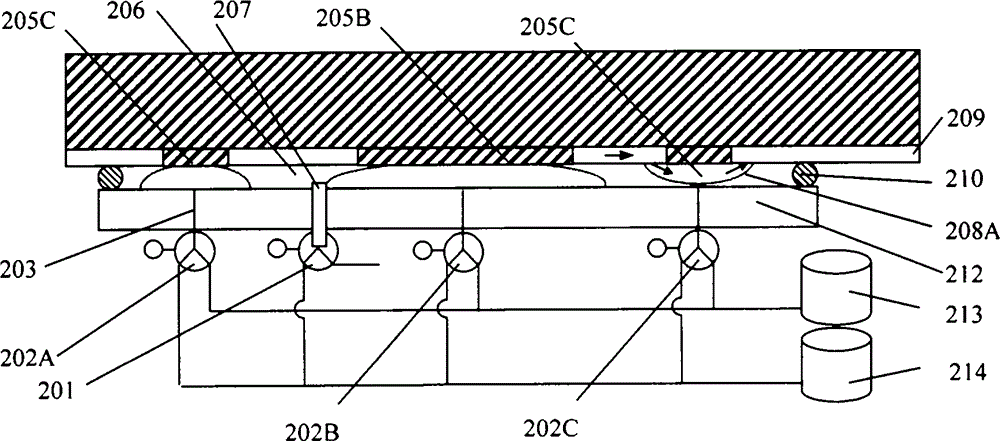

[0012] The solution of the present invention can drive the micromembrane pump to realize the two-way movement of the fluid. In this example, the compressed gas bottle 213 is used to store the positive pressure gas. The channel 203 is connected to the vacuum bottle 214 and the compressed gas bottle 213 through the three-way valve 202A, 202B, and 202C. The three-way valve 202A, 202B, 202C control positive and negative pressure in channel 203 . Compressed air 204 is used to impart positive pressure to the resilient sealing cap. The fluid-driven process is divided into two steps: suction and discharge.

[0013] Such as Figure 2a Shows the inhalation process. The three-way valve 201 connects the sealed space 206 to negative pressure, and the chips are pressed against the chip tray 212 . When the three-way valve 202A is switched to negative pressure, and 202C is switched to positive pressure, the diaphragm 205A is opened, the diaphragm 205C is pressed, the corresponding fluid ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com