Control device and control method of plate combiner

A technology of control device and control method, which is applied in the direction of program control and electrical program control in sequence/logic controllers, can solve problems such as large dust and chaotic boards during operation, and achieve stable operation, reduced quantity, and avoiding chaotic The effect of the plate phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

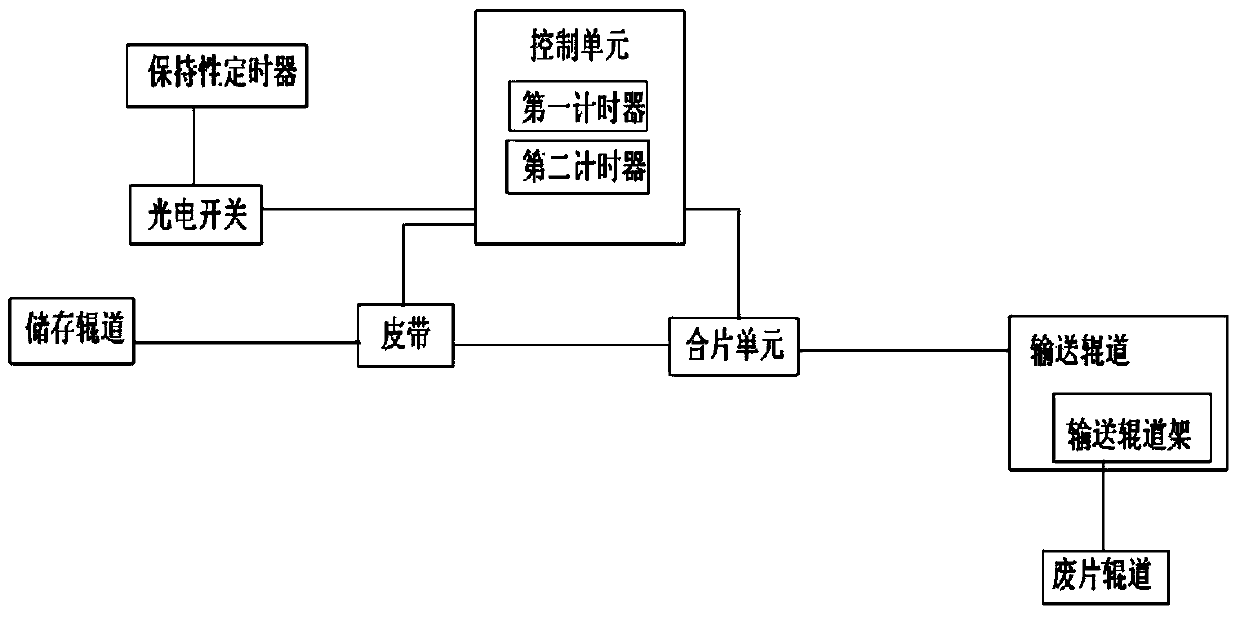

[0015] Such as figure 1 As shown, the control device of this laminator includes a photoelectric switch, a retentive timer, and a control unit; the photoelectric switch is installed above the storage roller table of the laminator; the retentive timer records from the photoelectric switch The time t0 from sensing the board to the belt of the combining machine starts to decelerate, the time t1 from the photoelectric switch sensing the board to the stop of the belt of the combining machine, the time t2 from the photoelectric switch sensing the board to the operation of the combining machine; the control unit They are respectively connected to the photoelectric switch, the belt, and the assembling unit; the control unit includes a first timer, which starts timing when the photoelectric switch senses a plate, and when t0 is reached, the control unit controls the belt to decelerate, and when t1 is reached, the control unit controls the belt to stop , when t2 is reached, the control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com