Jet device having storage chamber

A technology of spraying device and nozzle, which is applied in the direction of spraying device, liquid spraying device, and device for coating liquid on the surface, etc., which can solve the problems of easy-to-break spraying distance and shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

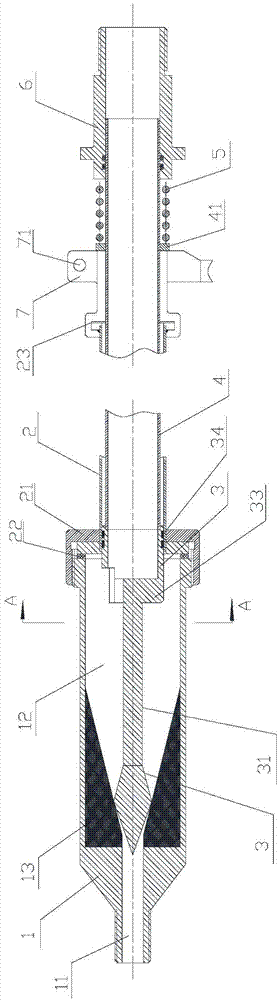

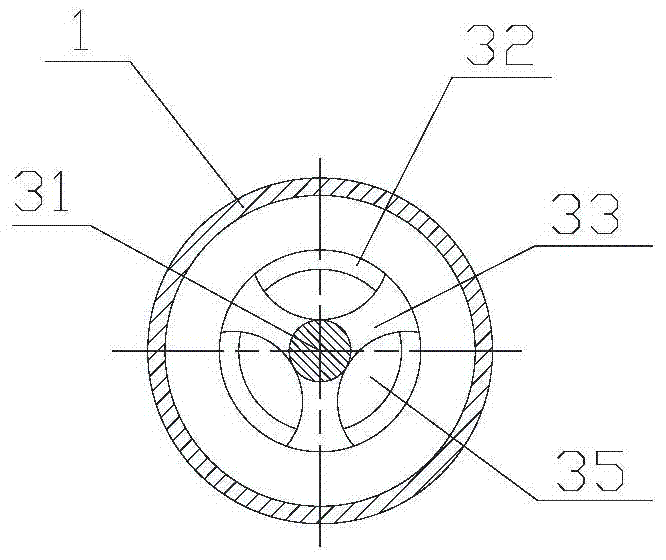

[0032] figure 1 A schematic structural view of an injection device with a storage chamber according to an embodiment of the present invention, as shown in figure 1 As shown, the injection device with a storage chamber of the present invention includes: a spray head 1 , a spray pipe 2 , a valve core 3 and an elastic member 5 . Wherein, the spray head 1 has a spray head cavity and a nozzle 11 communicating with the spray head cavity, and a valve seat 13 is provided on the inner wall of the spray head cavity. In this embodiment, the valve seat 13 is arranged at the position where the nozzle cavity and the nozzle 11 meet, so that the matching position of the valve core 3 and the valve seat 13 is also at the position where the nozzle cavity and the nozzle 11 meet, When the valve core 3 is disengaged from the valve seat 13, the liquid passes through the valve seat 13 and directly enters the spout 11 to be sprayed out. There is almost no loss of liquid pressure before being sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com