Single-channel gas and natural gas dual-purpose burner for heating furnace and using method thereof

A natural gas, single-channel technology, applied in the field of steel rolling equipment, can solve the problems of low cost of coke oven gas preparation, increase of enterprise cost investment, shutdown of hot rolling production line, etc., and achieve the goal of reducing residue, improving utilization rate and reducing pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

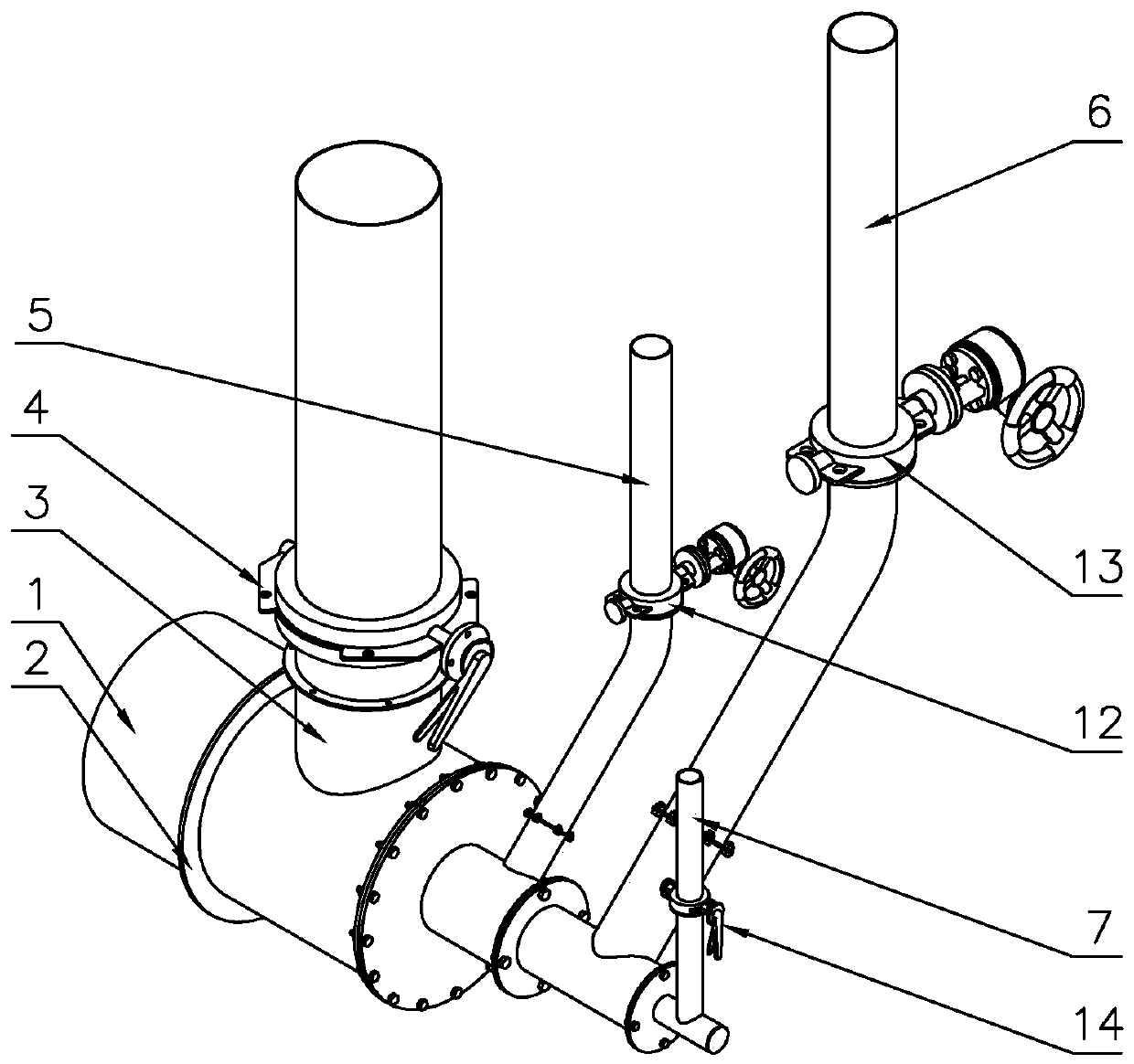

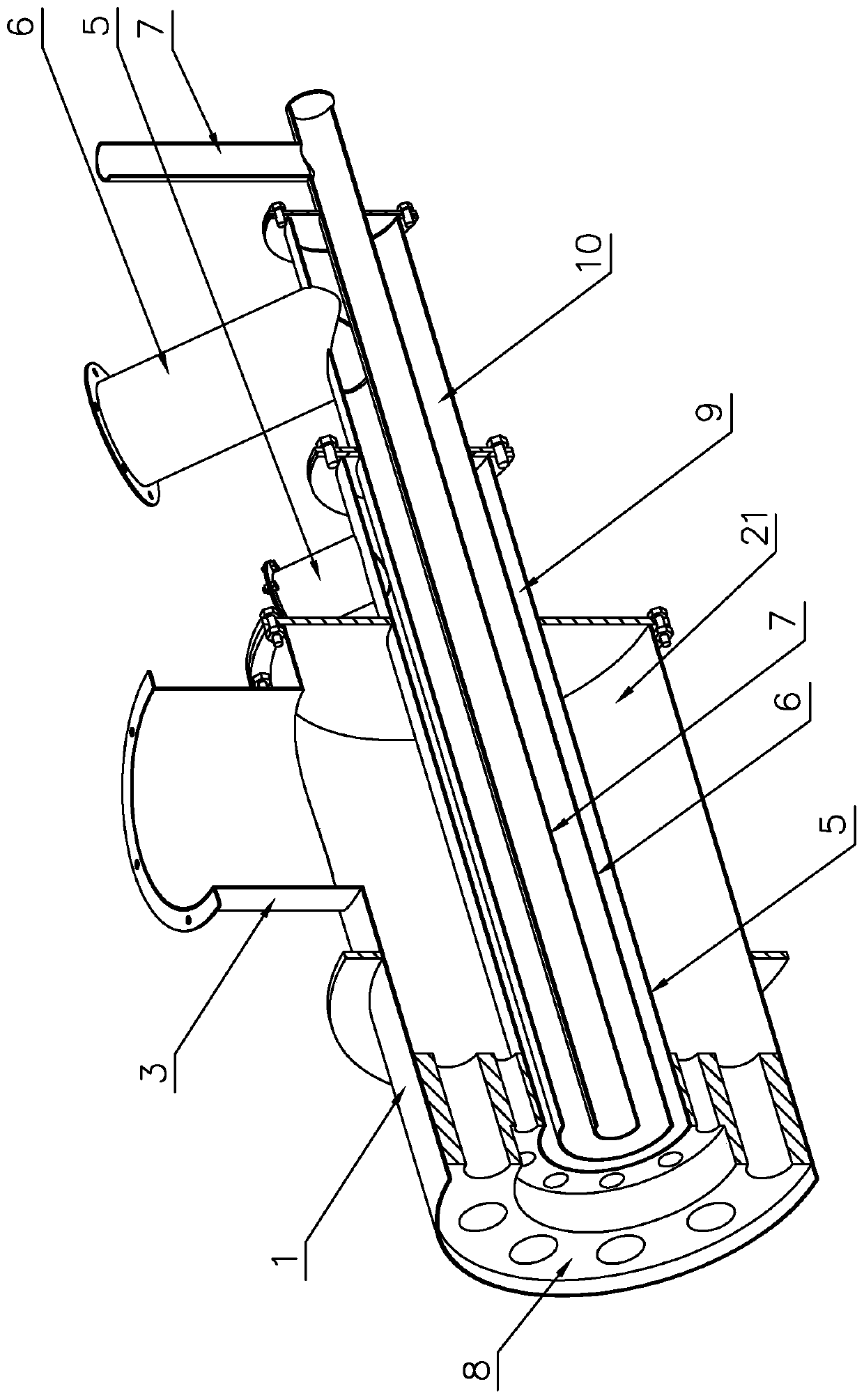

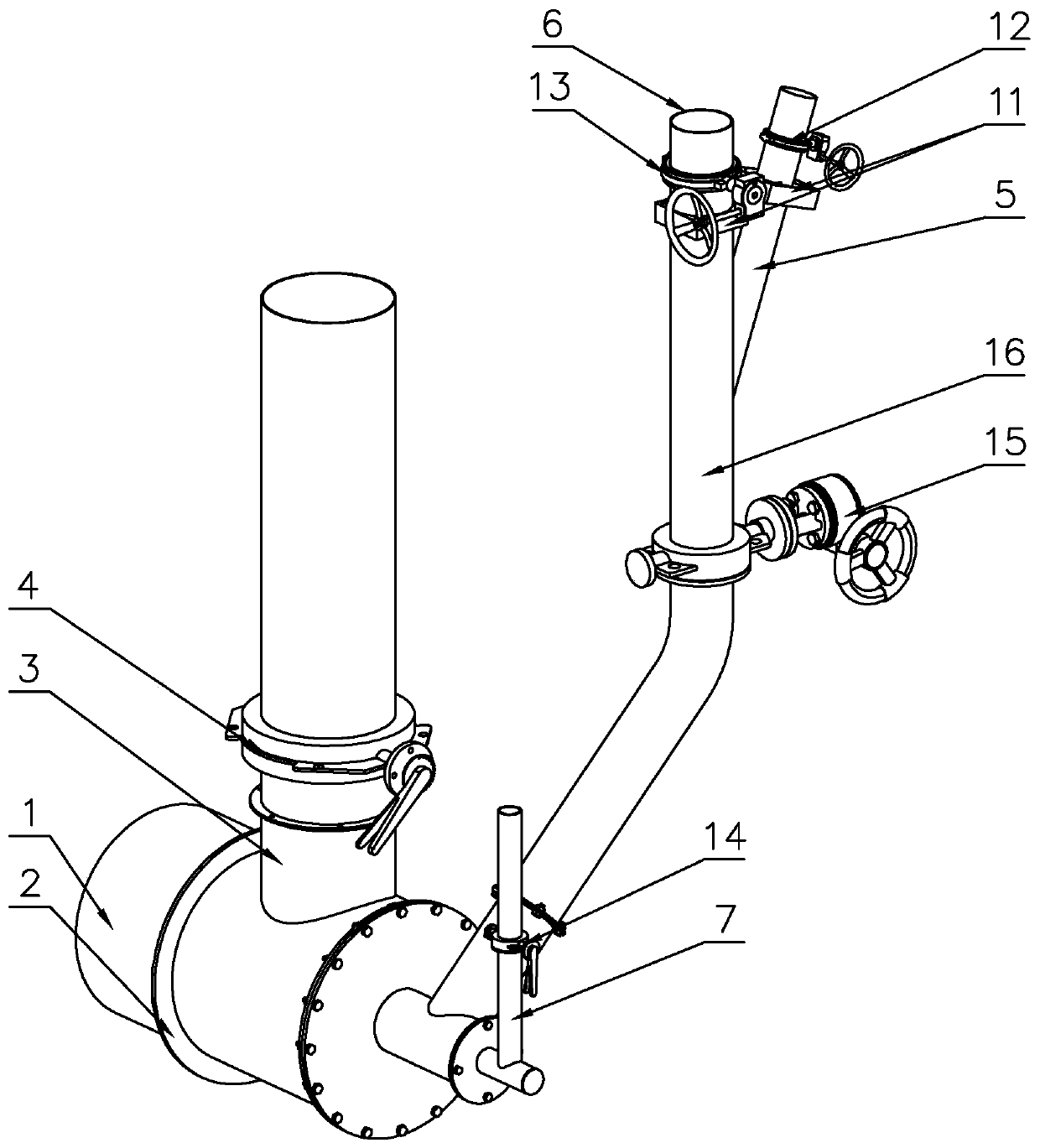

[0028] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-4 , to further specifically describe the technical solution of the present invention.

[0029] A dual-purpose burner for single-channel gas and natural gas for a heating furnace, comprising a shell 1, a combustion-supporting air pipe 3, a fuel pipe 16, a central air pipe 7, an air distribution plate 8, and a disc 19. The shell 1 is provided with There is a flange 2, which is used to fix the burner on the heating furnace. The shell 1 is provided with a combustion-supporting air pipe 3, and the side of the combustion-supporting air pipe 3 is provided with a butterfly valve I4, and the external air enters through the combustion-supporting air pipe 3. The interior of the burner provides oxygen for fuel combustion and provides pressure for the length of flame injection; a fuel pipeline 16 is provided on one side of the interior of the housing 1, and the fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com