Optical fiber connector and optical fiber connector assembly using the optical fiber connector

An optical fiber connector and contact technology, applied in the field of optical fiber connectors and connector components, can solve the problems of bending guide pins, weak anti-vibration and shock resistance of optical fiber connectors, affecting the use of connectors, etc. bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

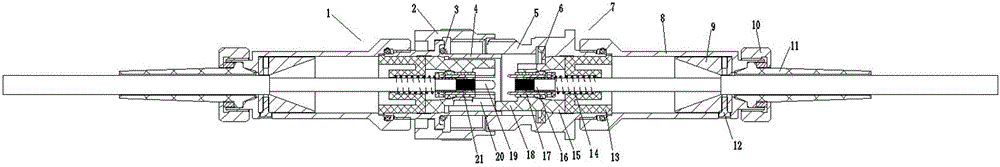

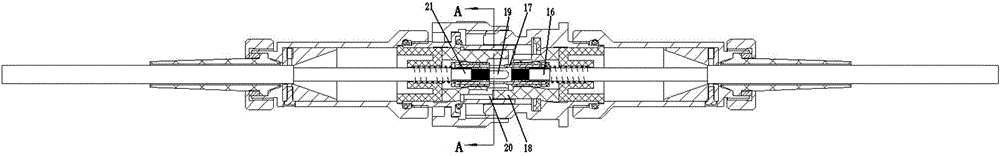

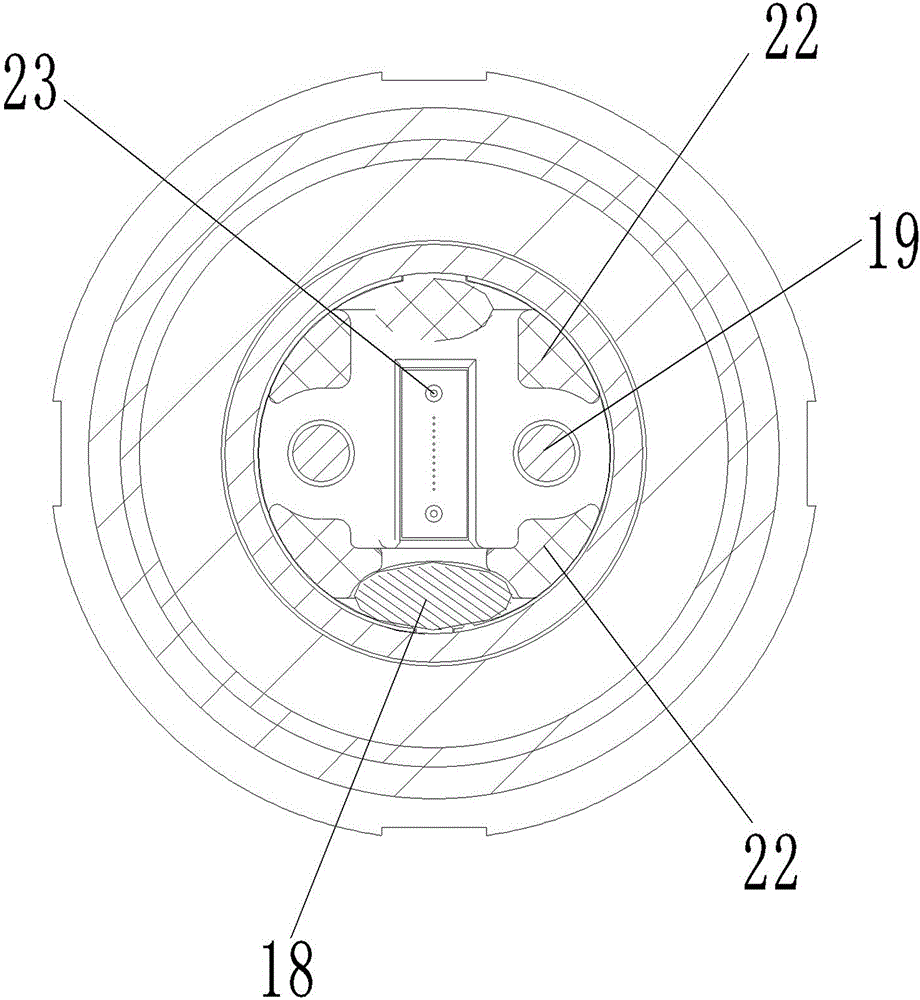

[0028] Examples of fiber optic connector assemblies are Figure 1~11 Shown: including plug 1 and socket 7, the plug and socket are circular connectors, the plug includes a plug housing 4 with the front end as the insertion end, the socket includes the socket housing 5 with the front end as the insertion end, and the plug housing 4 passes through The plug fixing part is fixed with a plug MT contact part 21 having a guide pin hole 23, and a socket MT contact part 16 having a guide pin 17 is fixed in the socket housing through the socket fixing part, and the plug MT contact part 21 and the socket MT contact part 16 are both It belongs to the prior art, and its specific structure is no longer described in detail. The plug housing 4 is screwed with a connecting nut 2, the socket housing 5 is provided with an external thread that matches the connecting nut, and the socket housing is provided with a socket housing that limits the tightening limit of the connecting nut along the tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com