Car battery holder

A battery and fixing frame technology, applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems of shortening the battery life, difficult disassembly, adverse battery heat dissipation, etc., to achieve the effect of easy installation and layout, and favorable heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0022] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

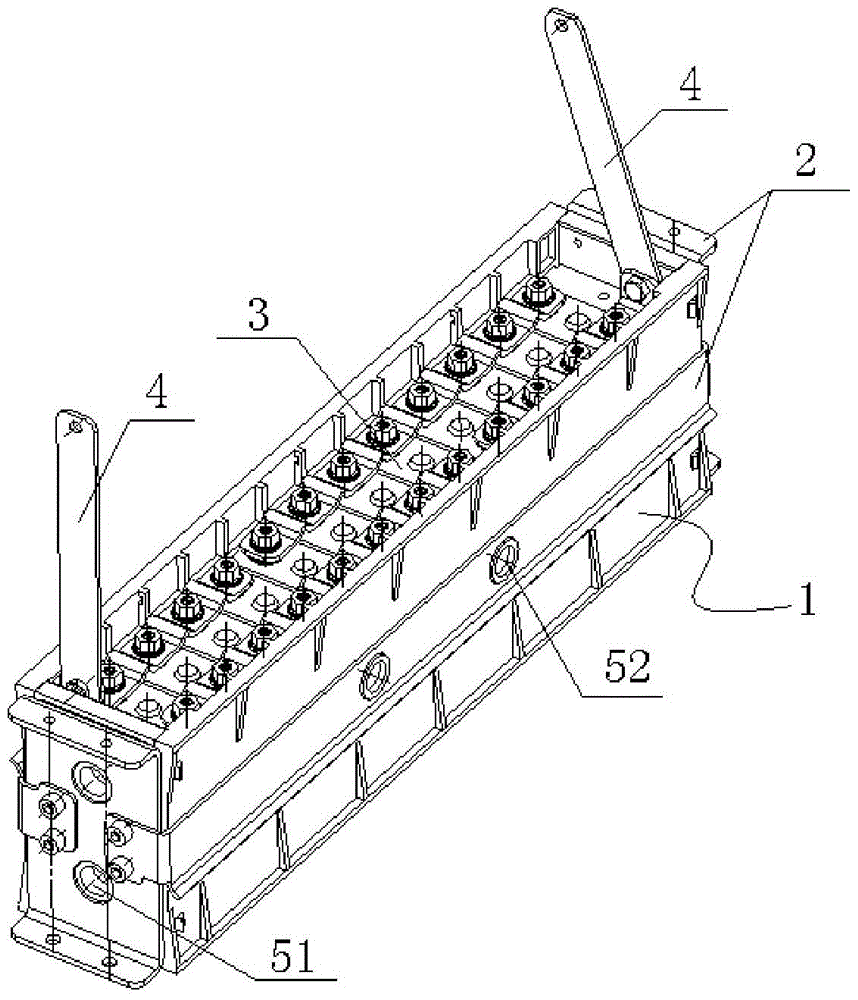

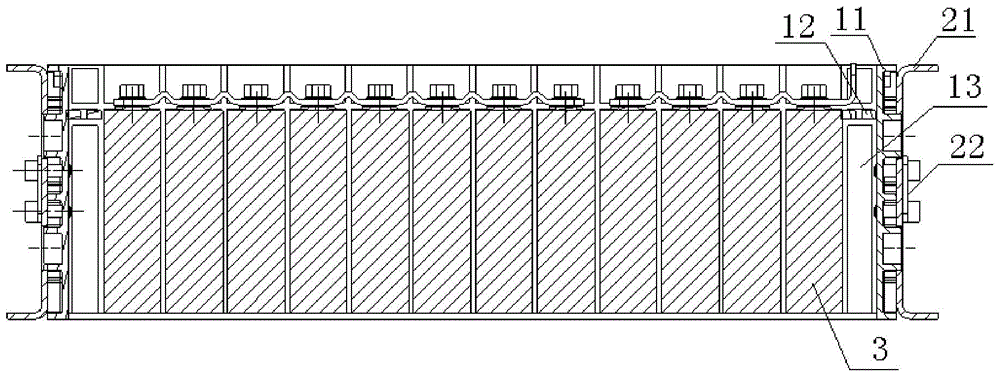

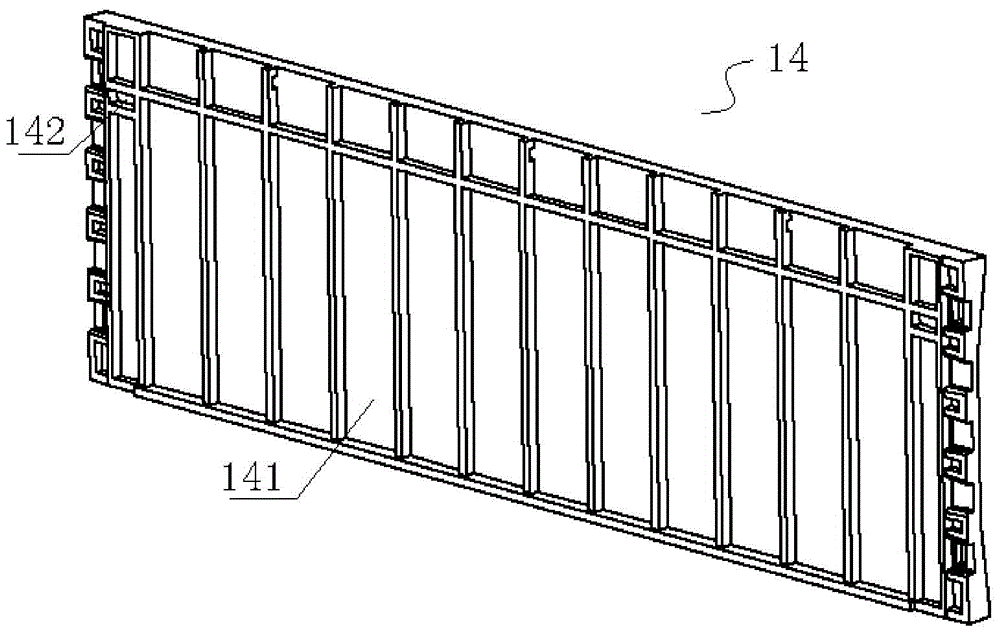

[0023] Such as figure 1 and figure 2 As shown, a vehicle battery fixing frame according to a specific embodiment of the present invention includes a rectangular frame 1 and a mounting frame 2, wherein the rectangular frame 1 includes two side plates 14 (see image 3 ) and two end plates 11, the rectangular frame 1 is formed by connecting the side plate 14 and the end plate 11 through two end cards in turn (the card struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com