Door sealing structure for horizontal shaft washing machine and horizontal shaft washing machine

A technology for washing machines and horizontal shafts, applied in the field of horizontal shaft washing machines and door seal structures for horizontal shaft washing machines, which can solve the problems of surface elastic tension decline, water leakage of washing machines, water leakage of horizontal shaft washing machines, etc., and achieve the effect of low cost and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example approach

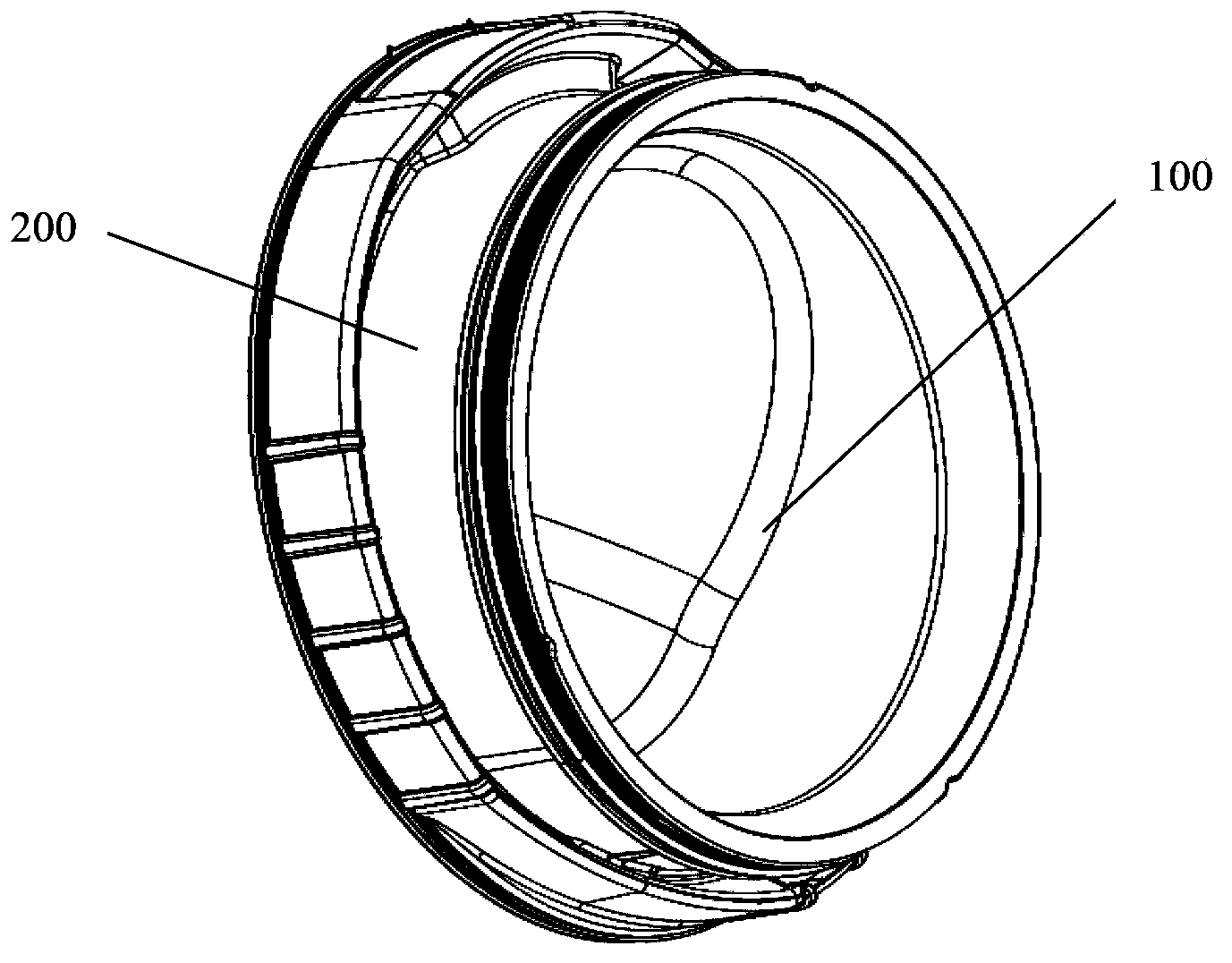

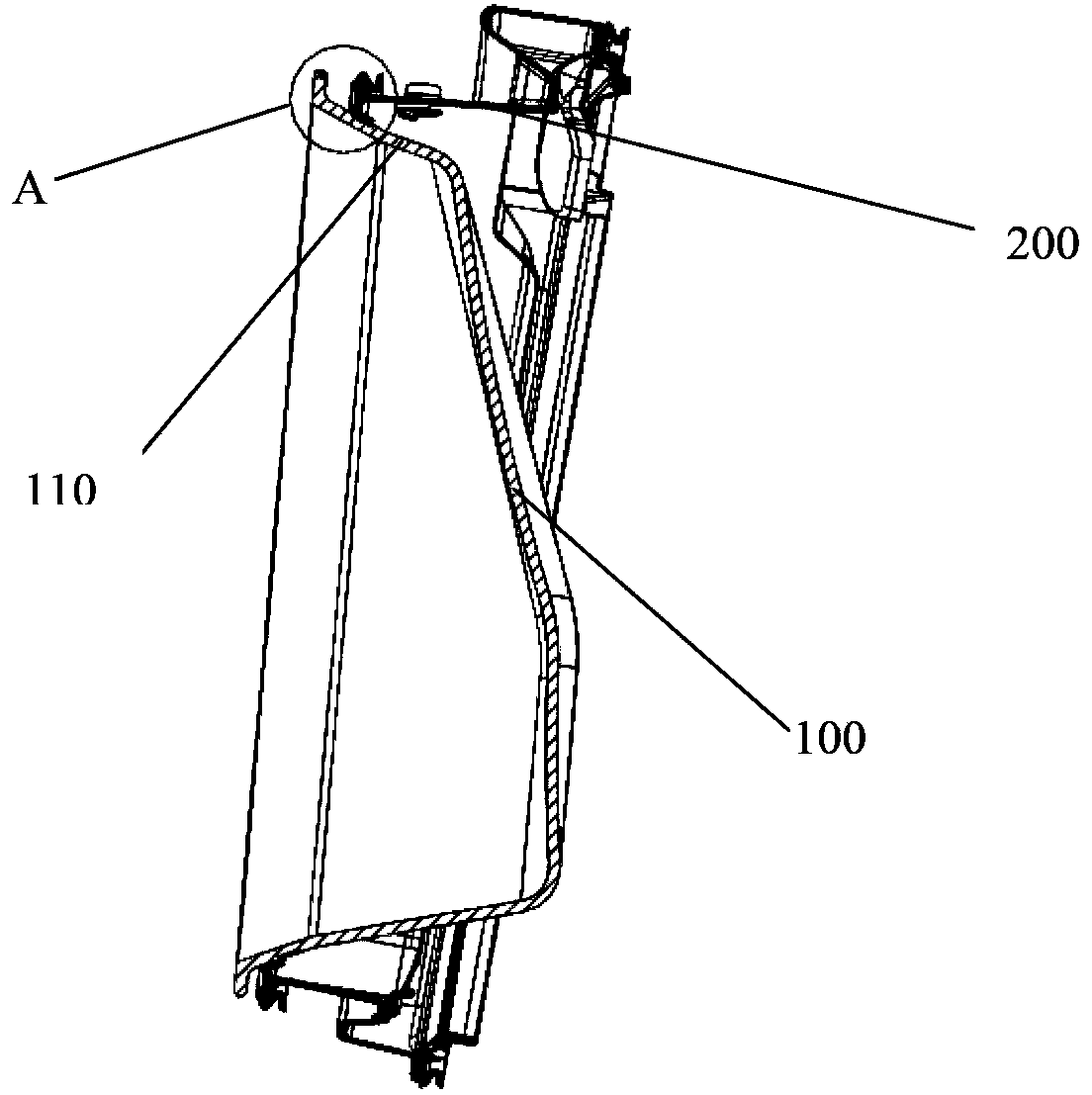

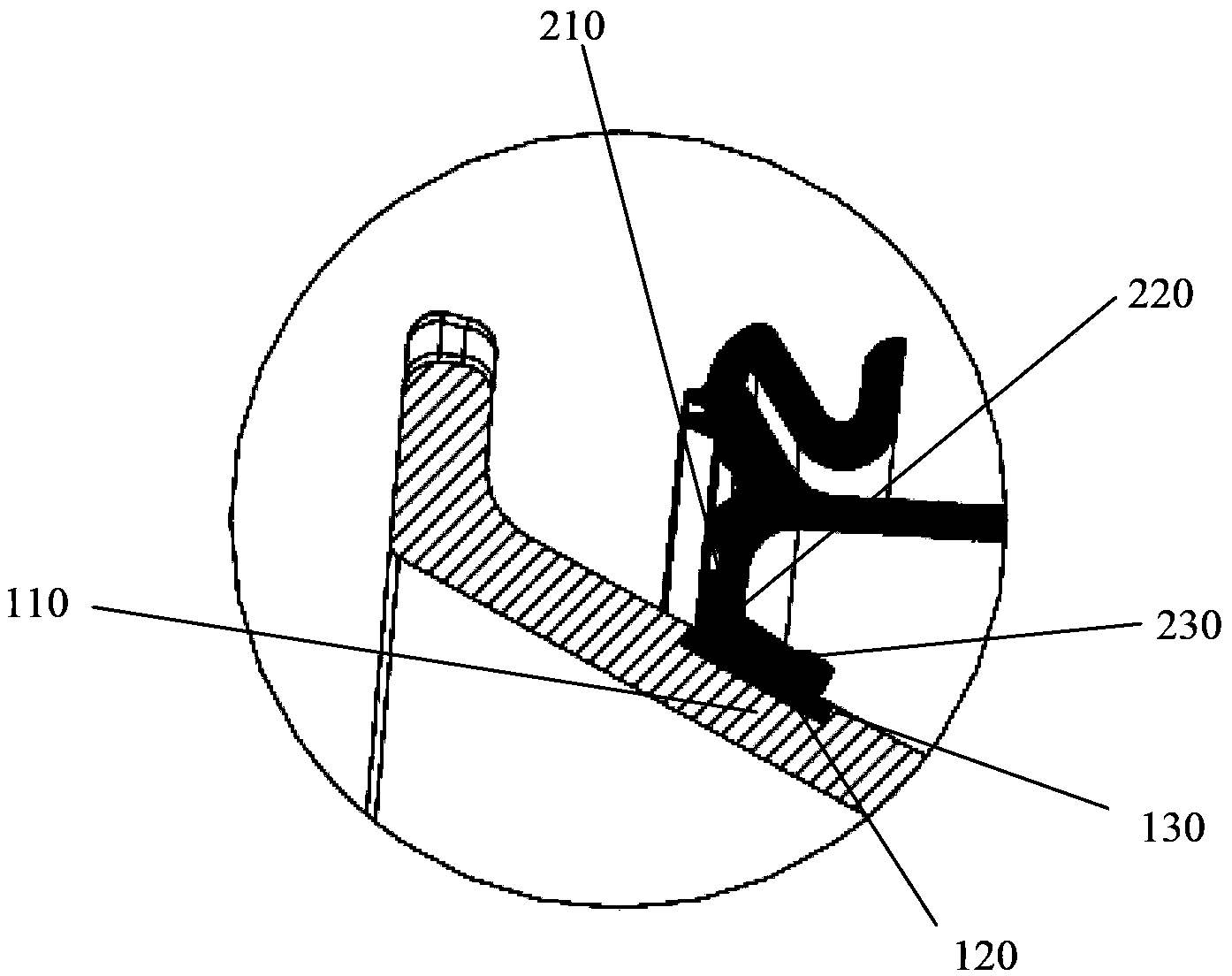

[0070] see figure 1 , figure 2 and image 3 , figure 1 It is a schematic diagram of the three-dimensional structure of the door seal structure in the first embodiment of the present invention, figure 2 yes figure 1 sectional view of image 3 yes figure 2 The enlarged schematic diagram of the structure at A. Such as figure 1 , figure 2 and image 3 The shown door seal structure for a horizontal axis washing machine, including:

[0071] The door panel includes a door panel body (not shown in the figure) and a protrusion 100 fixedly installed on the inner side of the door panel body. The protrusion 100 is made of transparent glass material, which can also be called door glass;

[0072] The opening of the washing machine body (not shown in the figure) arranged on the door panel and used for putting in clothes;

[0073] The door seal lip 200 installed around the opening of the washing machine body, the door seal lip 200 is ring-shaped, made of elastic rubber material...

no. 2 example approach

[0079] See also figure 1 , figure 2 and image 3 Compared with the first embodiment of the door seal structure for the horizontal axis washing machine shown, the second embodiment differs only in that the magnetic attraction structure includes a first magnet and a second magnet, and the first magnet is a first annular The magnet, the first ring-shaped magnet is fixedly arranged in the groove of the cone surface by double-sided adhesive bonding, and the height of the first ring-shaped magnet is basically flush with the height of the groove, so that the cone surface is basically a complete surface; The second magnetic conductor is a second ring magnet, which is fixedly arranged inside the socket surface by injection molding or vulcanization molding;

[0080] When the door panel body integrated with the protrusion is closed, the first ring magnet and the second ring magnet are in indirect contact through the sleeve surface, and the magnetic attraction force is generated throug...

no. 3 example approach

[0084] See also figure 1 , figure 2 and image 3 Compared with the first embodiment of the door seal structure for the horizontal axis washing machine shown, the third embodiment differs only in that the magnetic attraction structure includes a first magnet conductor and a second magnet, and the first magnet conductor is annular Metal flakes, the ring-shaped metal flakes are fixedly arranged in the groove of the cone surface by splicing and fitting, and the height of the ring-shaped metal flakes is basically the same as the height of the groove, so that the cone surface is basically a complete surface; the second guide The magnet is a ring magnet, which is fixed inside the socket surface by injection molding or vulcanization molding;

[0085] When the door panel body integrated with the protrusion is closed, the ring-shaped metal sheet and the ring-shaped magnet indirectly contact through the socket surface, and the magnetic attraction force is generated through the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com