Fastening clamp for web side formwork of stiffened concrete beam

A concrete beam and concrete technology, which is applied to the connection of formwork/formwork/work frame, the preparation of building components on site, and construction, etc., can solve the problem of inaccurate alignment of web holes and formwork holes, and failure of pulling screws. To avoid problems such as wear and affect the progress of the project, to avoid construction difficulties, high guarantee rate, and ensure the effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

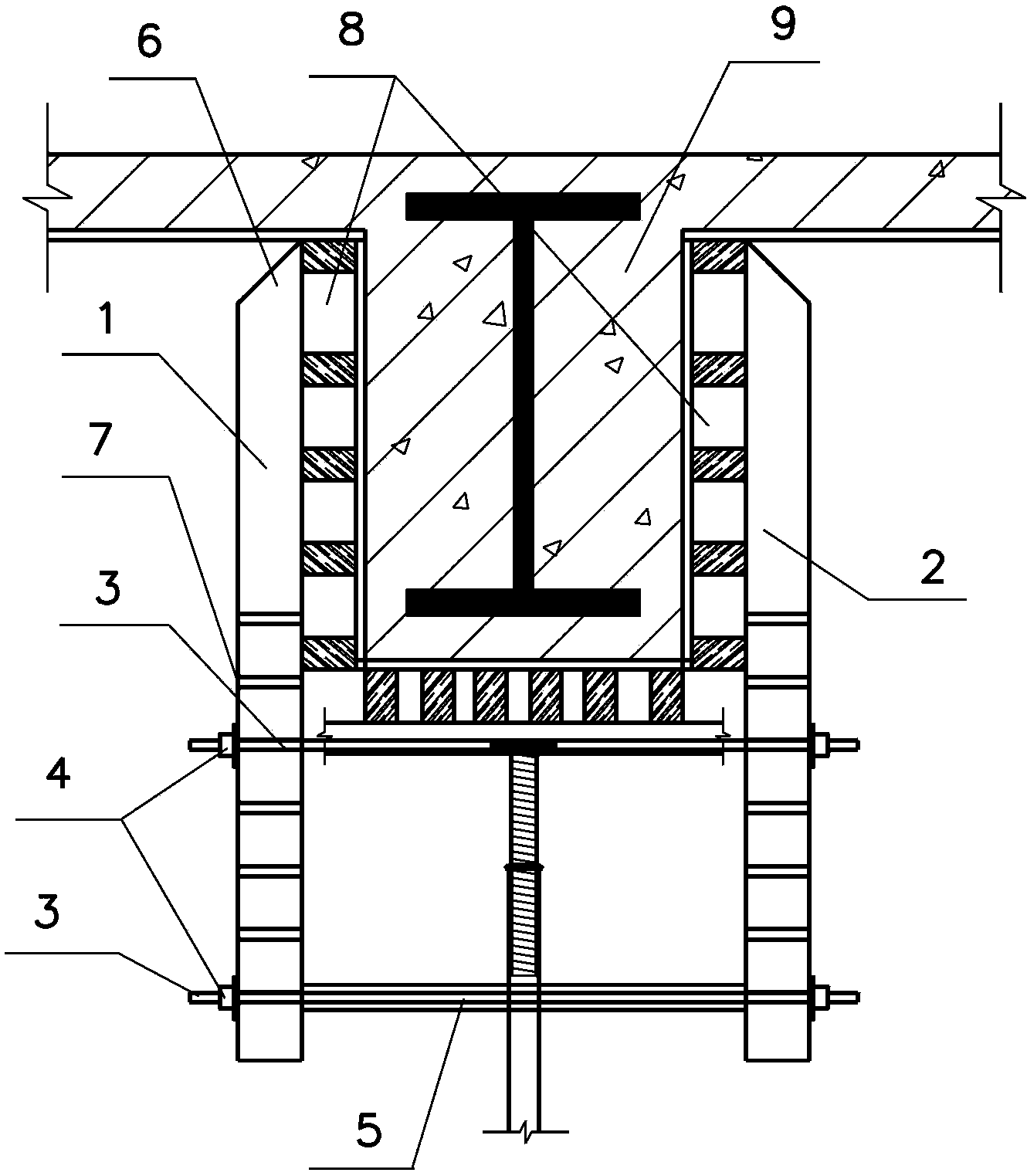

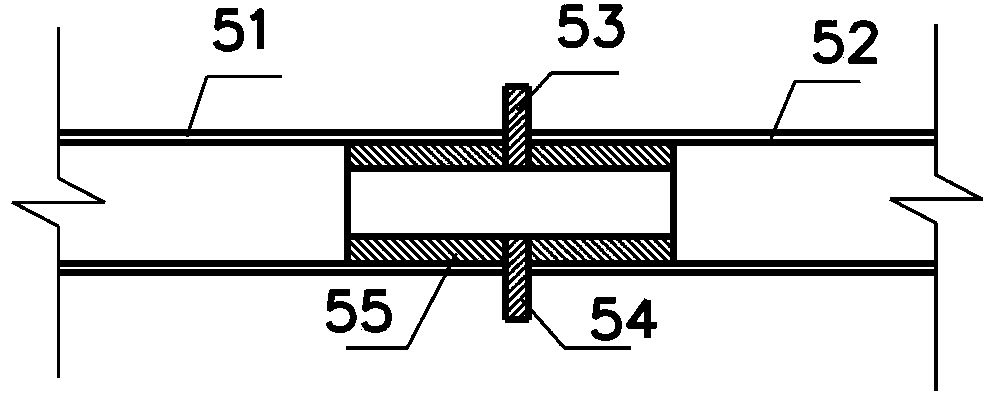

[0010] The specific implementation will be described in detail below in conjunction with the accompanying drawings: Figure 1 ~ Figure 2 One embodiment of the invention is shown. In the figure, a reinforcement fixture for the ventral formwork of a stiffened concrete beam includes: several fixture units, the fixture unit consists of a left side rod 1, a right side rod 2, a pull screw 3 and a nut 4, and a limit sleeve rod 5 composition. One side rod ends of the left side rod 1 and the right side rod 2 are provided with grooves 6, and there are several equally spaced pull screw rods from the middle section of the left side rod 1 and the right side rod 2 to the other side of the rod section. The holes 7 through which the left side bar 1 and the right side bar 3 are grooved are attached to the ventral formwork 8 of the stiffened concrete beam, and the middle section and the tail section of the left side bar 1 and the right side bar 2 Each pair is provided with a pull screw 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com