Hydrostatic axial piston machine utilizing a bent-axis construction

An axial piston engine, hydrostatic technology, applied in the direction of reciprocating piston engine, variable displacement engine, liquid fuel engine, etc. Transmission device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

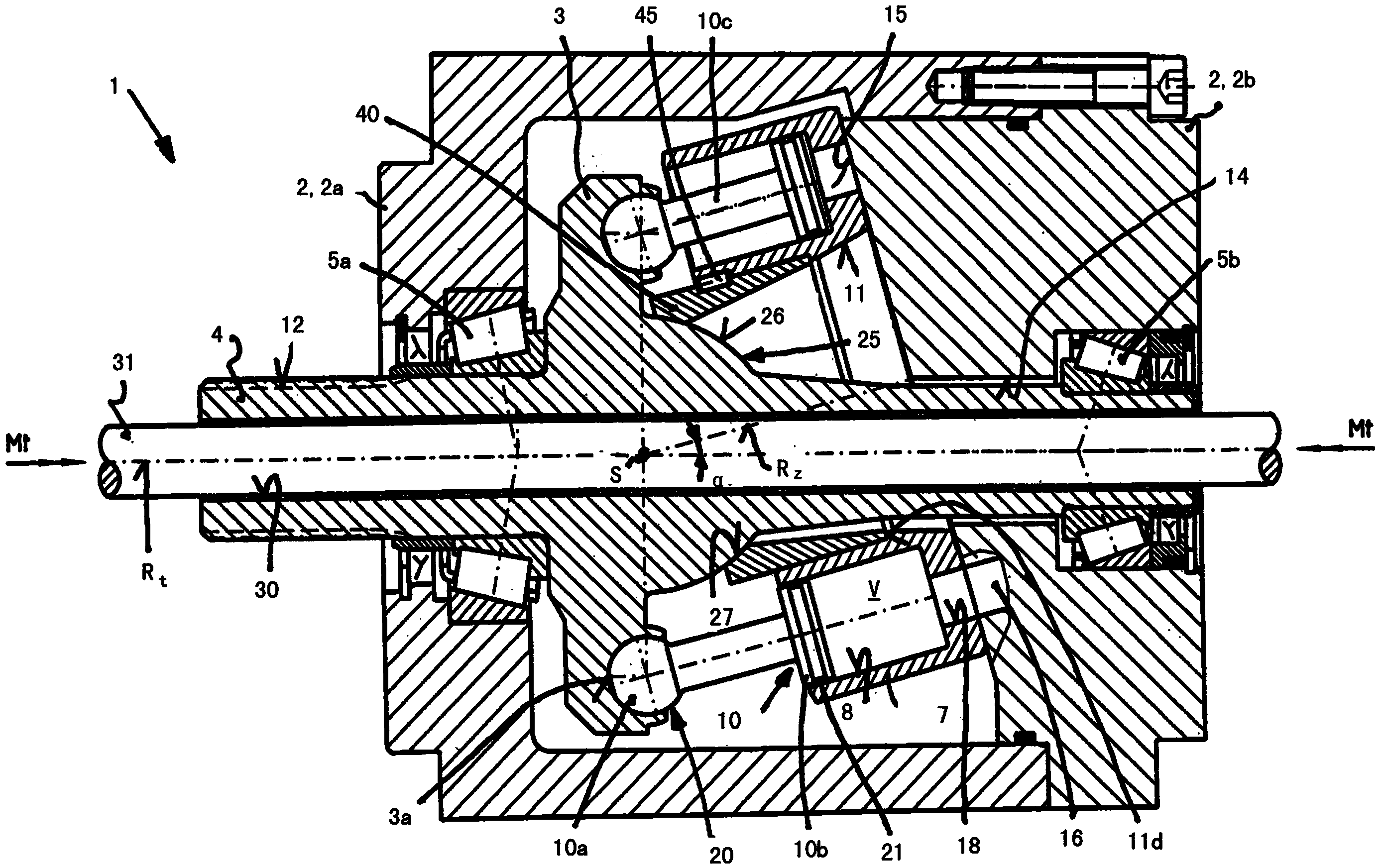

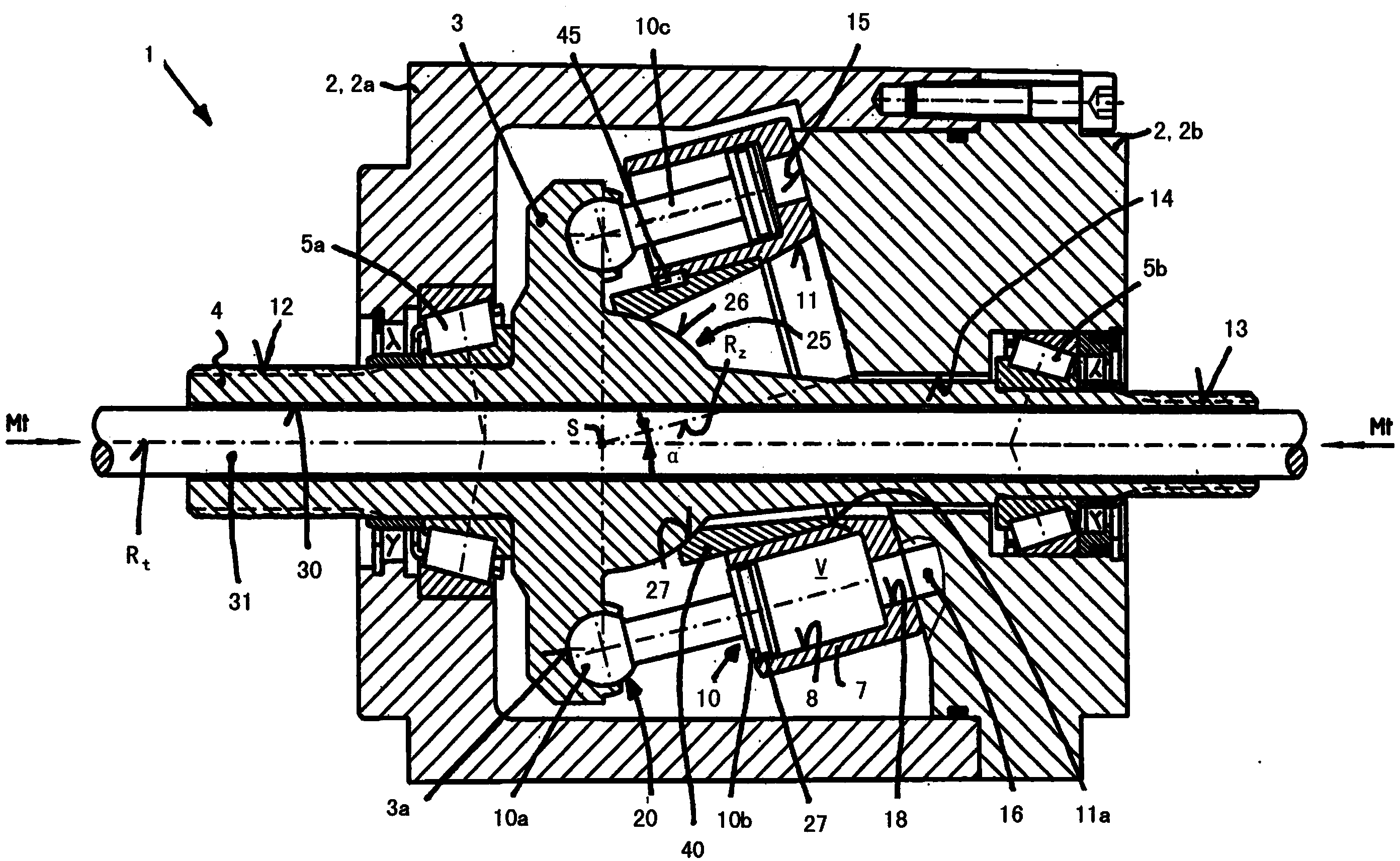

[0025] The hydrostatic axial piston machine 1 constructed as a bent axis machine according to the present invention is based on figure 1 There is a housing 2 which includes a housing tank 2a and a housing cover 2b. The drive shaft 4 provided with the drive flange 3 can surround the axis of rotation R by means of bearings 5a, 5b t It is rotatably supported in the housing 2. In the illustrated embodiment, the drive flange 3 is integrally formed on the drive shaft 4.

[0026] A cylindrical drum 7 is arranged in the housing 2 axially adjacent to the drive flange 3, and the cylindrical drum is provided with a plurality of piston grooves 8, and the piston grooves and the cylindrical body rotate Rotation axis R of cylinder 7 z Set in the same center. The piston 10 is longitudinally movably arranged in each piston groove 8.

[0027] The axis of rotation R of the drive shaft 4 t With the axis of rotation R of the cylindrical drum 7 z Intersect at intersection S.

[0028] in figure 1 The ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com