Non-loading type nano-scale composite carbon-noble metal catalyst as well as preparation method and application thereof

A noble metal catalyst and nano-sized technology, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of incomplete exposure of active sites, low utilization of precious metals, and uneven distribution of precious metals. Hydrogen and thermal energy loss, dechlorination suppression effect is remarkable, and the synthesis method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

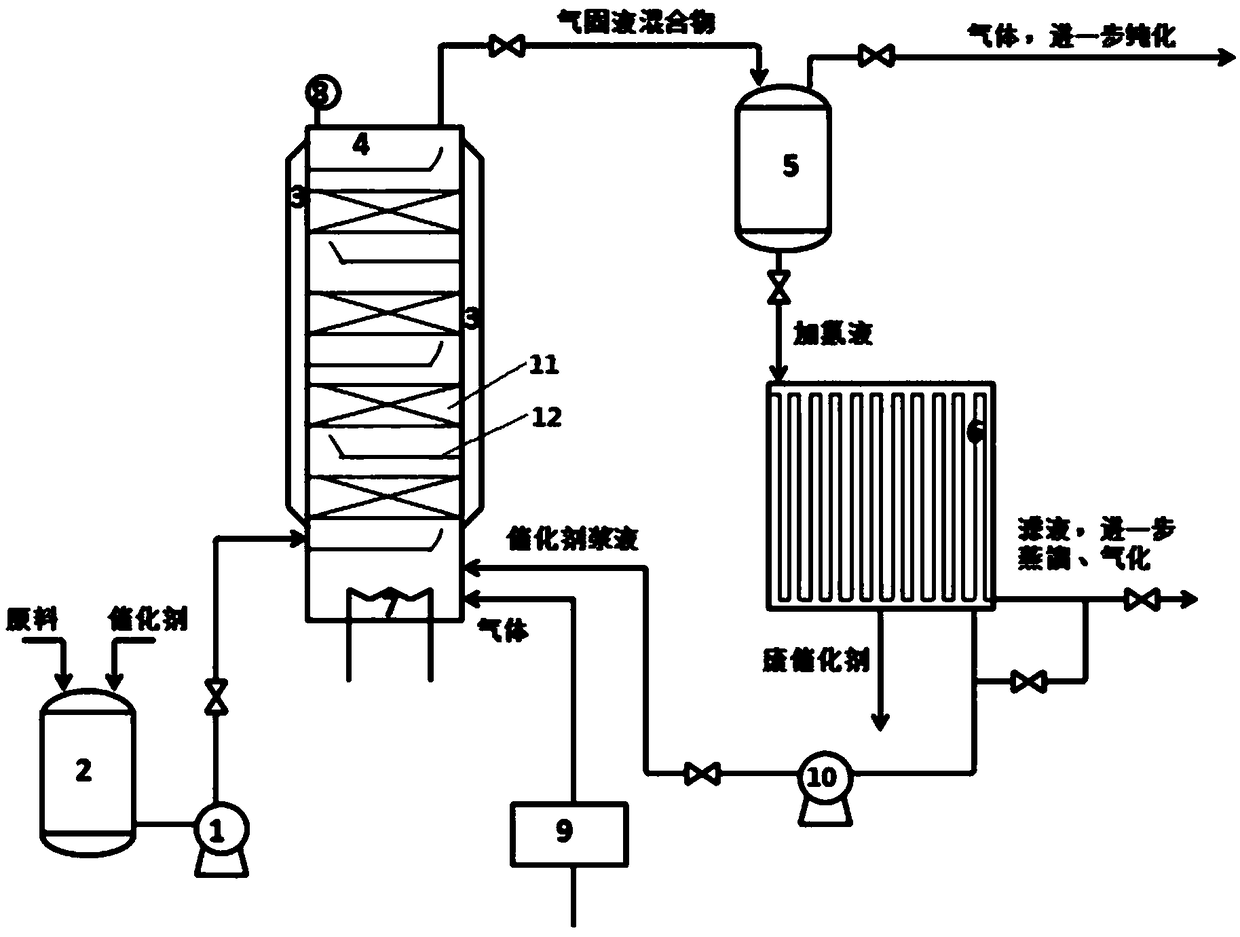

Method used

Image

Examples

Embodiment 1

[0057] A 0.001g / mL chloropalladium acid solution and a 0.001g / mL chloroplatinic acid solution were prepared using a conventional noble metal salt dissolution method. Mix 1 g of citric acid solid powder, 5 ml of chloropalladium acid solution, and 5 ml of chloroplatinic acid solution, set the temperature of the water bath at 30 ° C, start magnetic stirring for 3 hours, and after the stirring is completed, dry the mixed solution in a low-temperature vacuum (the low-temperature vacuum drying condition is a relative vacuum Degree -0.099MPa, temperature is -10 ℃, drying time 10h) to obtain the complex solid powder of citric acid and noble metal; ℃ / min to raise the temperature to 200°C, and keep it at 200°C for 0.5h. After the pyrolysis process is completed and the temperature is lowered to room temperature, slowly add 50ml of deionized water dropwise, and start magnetic stirring until the solid is completely dissolved. Finally, the solution is vacuum-dried at low temperature ( Low-t...

Embodiment 2

[0059] A 0.03 g / mL chloropalladium acid solution and a 0.03 g / mL palladium nitrate solution were prepared using a conventional noble metal salt dissolution method. Mix 2g of citric acid solid powder, 5ml of chloropalladium acid solution and 5ml of palladium nitrate solution, set the temperature of the water bath at 50°C, start magnetic stirring for 6 hours, and after the stirring is completed, dry the mixed solution under low-temperature vacuum drying to obtain a complex of citric acid and noble metal Solid powder (low temperature vacuum drying condition is relative vacuum degree -0.05MPa, temperature is 0°C, drying time is 24h); then, put the complex mixed solid powder in a round bottom flask, heat up to melting, and then dry at 5°C / min to raise the temperature to 300°C, and keep it at 300°C for 2 hours. After the pyrolysis process is completed and the temperature is lowered to room temperature, slowly add 50ml of deionized water dropwise, and start magnetic stirring until th...

Embodiment 3

[0061]A 0.001g / mL palladium nitrate solution and a 0.001g / mL rhodium dichloride solution were prepared using a conventional noble metal salt dissolution method. Mix 3g of citric acid solid powder, 5ml of palladium nitrate solution and 5ml of rhodium dichloride solution, set the temperature of the water bath to 40°C, start magnetic stirring for 4 hours, and after the stirring is completed, dry the mixed solution under low-temperature vacuum drying to obtain complexation of citric acid and precious metals solid powder (low temperature vacuum drying condition is relative vacuum degree -0.05MPa, temperature is -10°C, drying time is 24h); then, put this complex mixed solid powder in a round bottom flask, heat up to melting, and then Raise the temperature to 300°C at 5°C / min and keep it at 300°C for 2 hours. After the pyrolysis process is completed and the temperature is lowered to room temperature, slowly add 50ml of deionized water dropwise, and start magnetic stirring until the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com