A catalyst for hydrogenation of 2,2,4,4-tetramethyl-1,3-cyclobutanedione and its preparation method and application

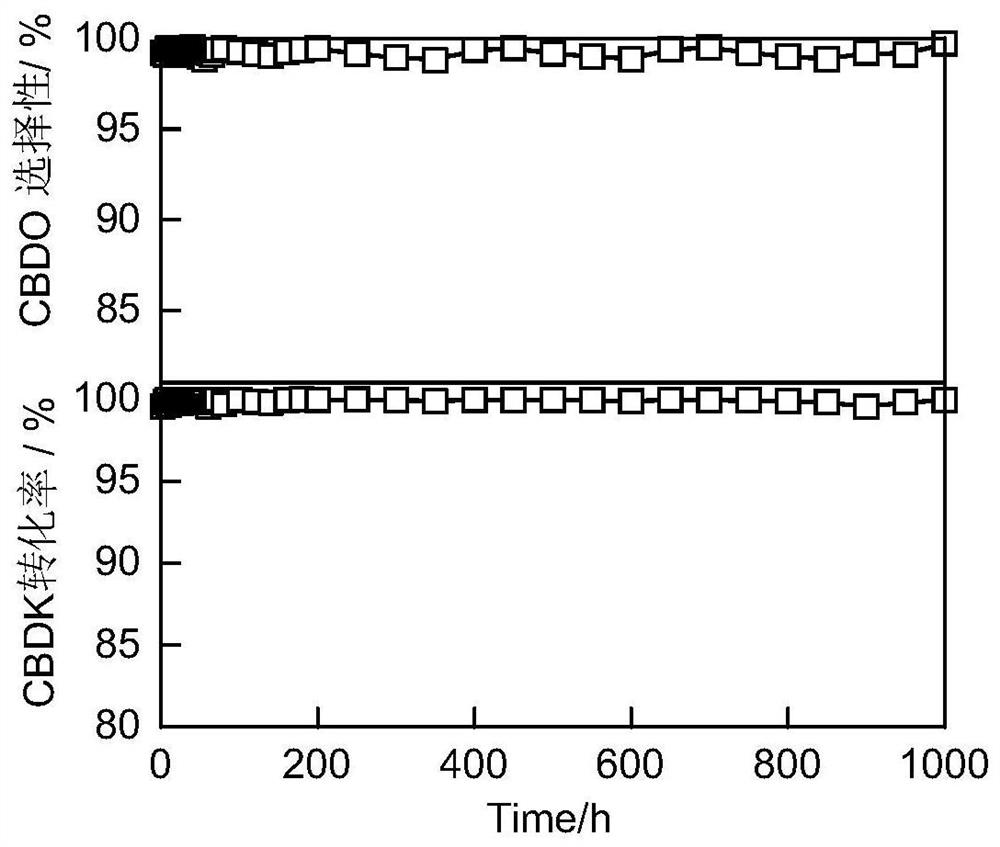

A technology of cyclobutanedione and tetramethyl, which is applied in the field of catalysts, can solve problems such as the need to improve and the decrease of CBDO selectivity, and achieve the effects of fast reaction rate, less by-products and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0100] First, a precursor aqueous solution of metallic Ni is prepared. Weigh a certain amount of nickel nitrate solid powder, add it to a 50ml volumetric flask, add 45ml of deionized water to dissolve it completely, and then add 5ml of deionized water to make up the volume to obtain 8mmol·L -1 Ni(NO 3 ) 2 solution.

[0101] Next, metallic Ni nanocolloids were prepared. 2.131g polyvinylpyrrolidone (PVP), 125mL Ni (NO 3 ) 2 (8mmol·L -1 ), PVP: Ni mol ratio is 20: 1, 330mL aqueous ethanol solution (ethanol: water mass ratio 10: 1) is added in the beaker successively, fully stirs 30min, makes PVP dissolve completely; Secondly, adopt water bath to heat the temperature to 80 ℃ , adjust the pH to 10-12, quickly add 50mL NaBH to the beaker 4 solution (38.4mmol·L -1 , the molar ratio of reducing agent:Ni is 2:1,), fully stirring (500r / min) and reacting for 3h to obtain nano-Ni particle sol.

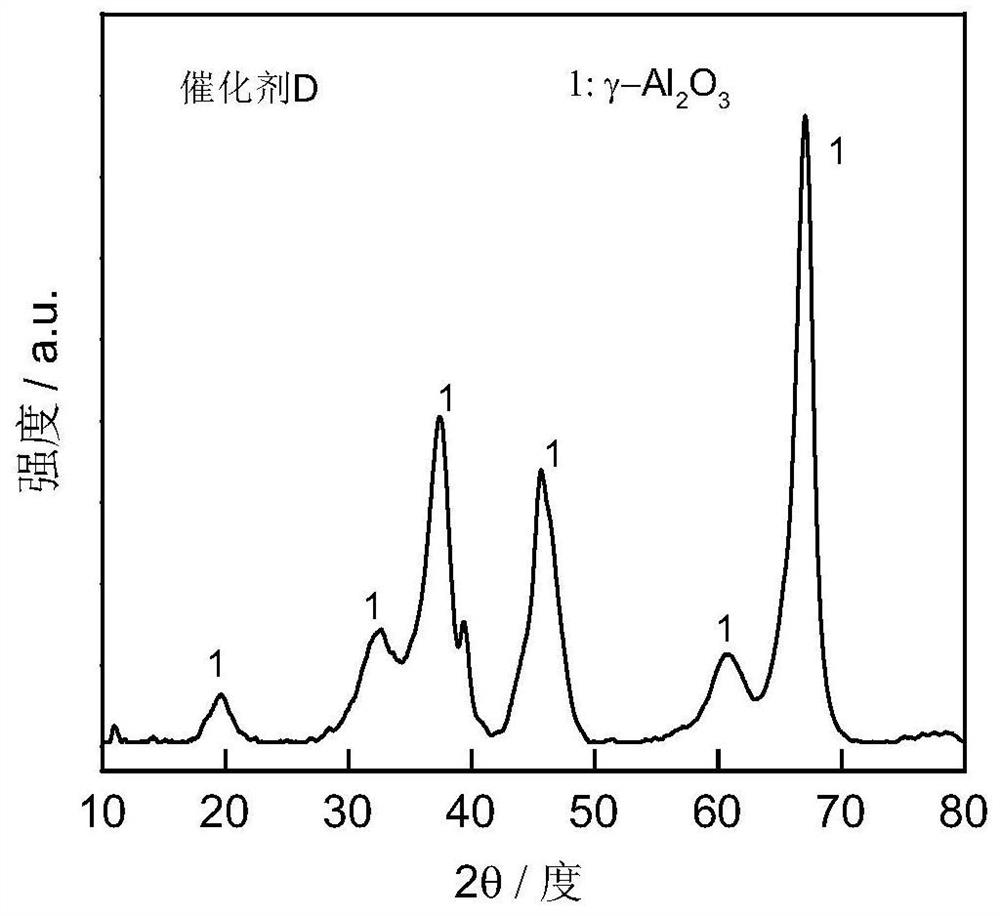

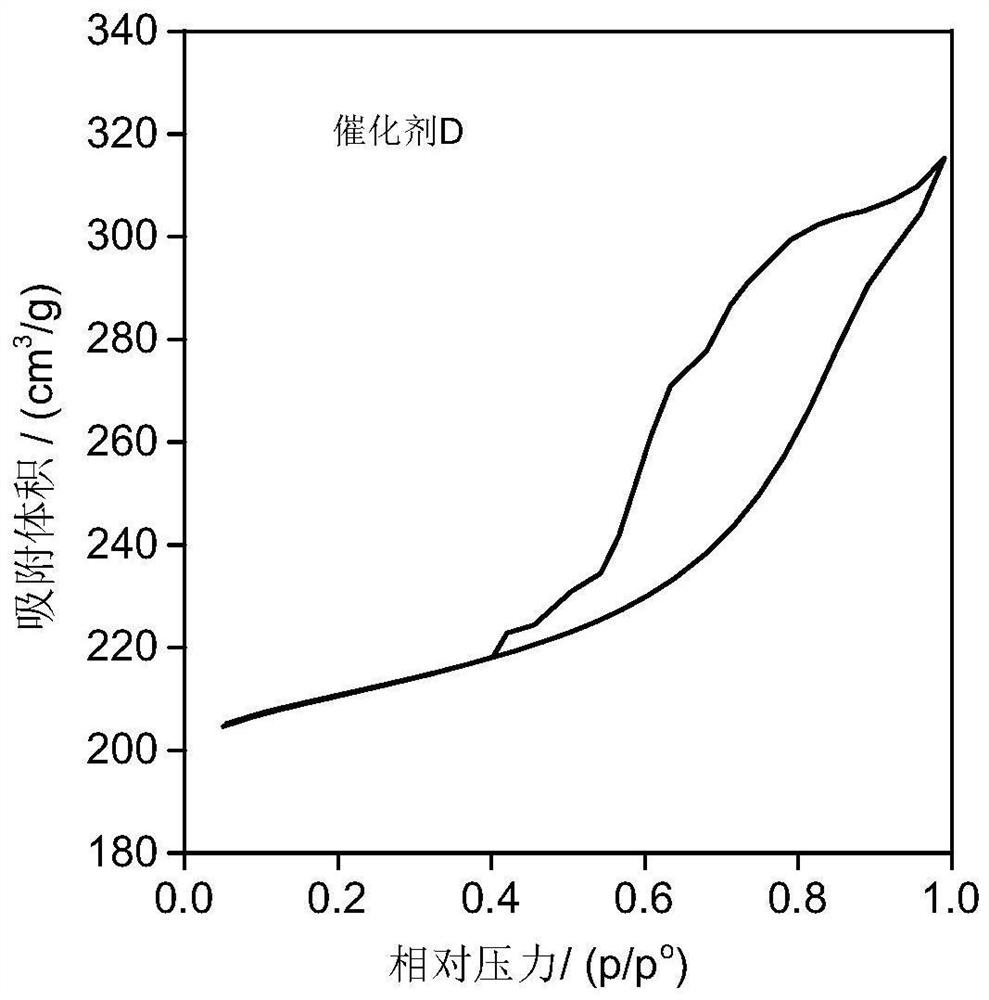

[0102] Finally, 5g γ-Al 2 O 3 It was added to the nano-Ni sol and stirred continuou...

preparation example 2

[0104] First, an aqueous precursor solution of metal Ru is prepared. Weigh a certain amount of RuCl 3 The solid powder was added to a 50ml volumetric flask, 45ml of deionized water and 3 to 5 drops of HCl (36% to 38%) solution were added to dissolve RuCl 3 The powder was completely dissolved, and deionized water was added to the volume to obtain 8 mmol·L -1 RuCl 3 solution.

[0105] Second, metal Ru nanocolloids were prepared. 2.131g polyvinylpyrrolidone (PVP), 125mL RuCl 3 (8mmol·L -1 ), PVP: Ru mol ratio is 20: 1, 330mL aqueous ethanol solution (ethanol: water mass ratio 10: 1) is added in the beaker successively, fully stirs 30min, makes PVP dissolve completely; Secondly, adopt water bath to heat the temperature to 40 ℃ , adjust the pH to 9-11, quickly add 50mL NaBH to the beaker 4 solution (38.4mmol·L -1 , the molar ratio of reducing agent:Ru is 2:1,), fully stirring (500r / min) and reacting for 3h to obtain nano Ru particle sol.

[0106] Finally, 5g γ-Al 2 O 3 I...

preparation example 3

[0108] First, a precursor aqueous solution of metallic Ni is prepared. Weigh a certain amount of nickel nitrate solid powder, add it to a 50ml volumetric flask, add 45ml of deionized water to dissolve it completely, and then add 5ml of deionized water to make up the volume to obtain 8mmol·L -1 Ni(NO 3 ) 2 solution. Similarly, a certain mass of copper nitrate and zinc nitrate solid powder were respectively weighed to prepare 33.3 mmol·L -1 Copper nitrate solution and 100mmol·L -1 Zinc nitrate solution.

[0109] Next, metallic Ni nanocolloids were prepared. 2.131g polyvinylpyrrolidone (PVP), 125mL Ni (NO 3 ) 2 (8mmol·L -1 ), PVP: Ni mol ratio is 20: 1, 330mL aqueous ethanol solution (ethanol: water mass ratio 10: 1) is added in the beaker successively, fully stirs 30min, makes PVP dissolve completely; Secondly, adopt water bath to heat the temperature to 80 ℃ , adjust the pH to 10-12, quickly add 50mL NaBH to the beaker 4 solution (38.4mmol·L -1 , the molar ratio of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com