Method for selective hydrogenation of phenol on Na-modified NiCo catalyst

A technology for selective hydrogenation and catalyst, applied in the field of catalysis, which can solve the problems of low conversion rate and long reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This Na-modified NiCo catalyst was prepared by the following method:

[0037] 1) Preparation of catalyst precursor Na-NiCo@C:

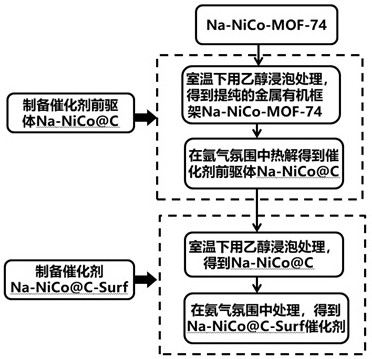

[0038] The synthetic route of Na-NiCo@C-Surf catalyst is as follows figure 1 As shown, the catalyst precursor Na-NiCo@C was first synthesized as follows:

[0039] Soak Na-NiCo-MOF-74 in ethanol solution at room temperature for 8 hours to remove surface residues, filter with suction, wash alternately with ethanol and water for 6 times, and dry in vacuum at 60°C for 18 hours to obtain pure Na-NiCo-MOF -74. Put pure Na-NiCo-MOF-74 in a tube furnace and pyrolyze it in an argon atmosphere. The temperature is raised from room temperature to 500 °C at a rate of 3 °C / min, kept at this temperature for 2 hours, and then dropped to room temperature , to obtain the carbon-coated nanoscale metal catalyst precursor Na-NiCo@C.

[0040] Wherein the preparation of Na-NiCo-MOF-74:

[0041] Add nickel acetate and cobalt acetate to distilled water to prepare ...

Embodiment 2

[0049] This Na-modified NiCo catalyst was prepared by the following method:

[0050] 1) Preparation of catalyst precursor Na-NiCo@C:

[0051] Soak Na-NiCo-MOF-74 in ethanol solution at room temperature for 24 hours to remove surface residues, filter with suction, wash with ethanol and water alternately 4 times, and dry in vacuum at 120°C for 8 hours to obtain pure Na-NiCo-MOF -74. Put pure Na-NiCo-MOF-74 in a tube furnace and pyrolyze it in an argon atmosphere. The temperature is raised from room temperature to 400 °C at a rate of 3 °C / min, kept at this temperature for 3 hours, and then dropped to room temperature , to obtain the carbon-coated nanoscale metal catalyst precursor Na-NiCo@C.

[0052] Wherein the preparation of Na-NiCo-MOF-74:

[0053] Add nickel acetate and cobalt acetate to distilled water to prepare a solution with a total metal salt concentration of 0.10 mol / L, wherein the molar ratio of nickel acetate and cobalt acetate is 1:4; add 2,5-dihydroxyterephthali...

Embodiment 3

[0059] This Na-modified NiCo catalyst was prepared by the following method:

[0060] 1) Preparation of catalyst precursor Na-NiCo@C:

[0061]At room temperature, the molar ratio of nickel and cobalt is 1:1.5, and the ratio of the molar weight of 2-hydroxypropane-1,2,3-tricarboxylic acid sodium to the total molar weight of the two metal salts is 1.5:7. -MOF-74 was soaked in ethanol solution for 16 hours to remove surface residues, filtered with suction, washed alternately with ethanol and water for 3 times, and dried in vacuum at 120°C for 8 hours to obtain pure Na-NiCo-MOF-74. Pure Na-NiCo-MOF-74 was placed in a tube furnace and pyrolyzed in an argon atmosphere. The temperature was raised from room temperature to 450 °C at a rate of 3 °C / min, kept at this temperature for 3 hours, and then dropped to room temperature , to obtain the carbon-coated nanoscale metal catalyst precursor Na-NiCo@C.

[0062] 2) Preparation of Na-NiCo@C-Surf catalyst:

[0063] Soak the obtained Na-Ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com