A kind of porous carbon-supported composite material catalyst and its preparation method and application

A composite material and catalyst technology, which is applied to the porous carbon-supported composite material catalyst and the field of preparation and application thereof, can solve the problems of unfavorable reduction of the use cost of the precious metal catalyst, decrease of metal utilization rate, etc., and achieves remarkable dechlorination inhibition effect and repeated application times The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

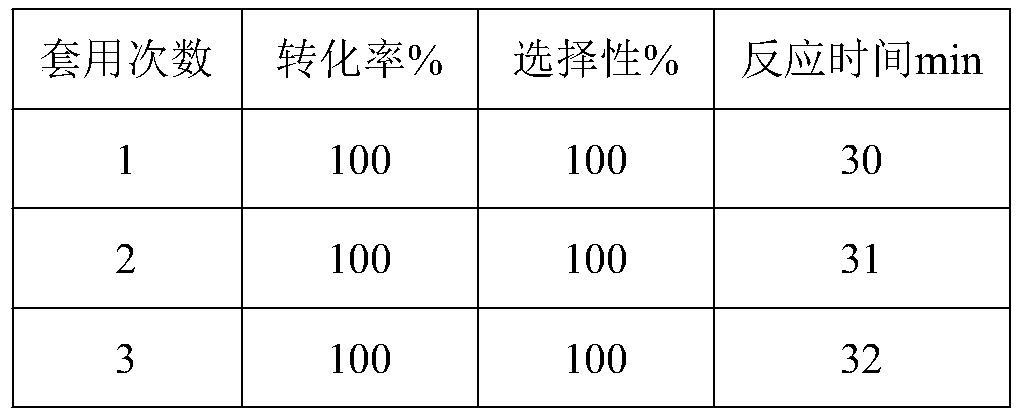

Examples

Embodiment 1

[0041] The physical parameters of the carrier activated carbon: the specific surface area is 1500m 2 / g, the proportion of micropore specific surface area is 75%, the ash content is 3.0wt%, and the pore volume is 0.5mL / g; the material of activated carbon is coconut shell.

[0042] Measure 5mL of ethylene glycol and 80mL of 0.1g / mL alanine solution, stir evenly, then transfer to a hydrothermal reactor and keep at 150°C for 24h, then transfer the reaction solution to a dialysis bag with a molecular weight cut-off of 1000 Carry out dialysis for 12 hours; then freeze-dry the dialysate at a relative vacuum degree of <-0.085MPa and a temperature of -10°C for 10 hours to obtain solid powder of quantum dots.

[0043] Then weigh 5g of activated carbon, put it in 50mL of 6mol / L hydrochloric acid solution for impurity removal and pore expansion treatment for 6h, the treatment temperature is 30°C, then filter and wash until neutral, then add 15mL of water to mix and stir, and drop Add hy...

Embodiment 2

[0046] The physical parameters of the carrier activated carbon: the specific surface area is 1800m 2 / g, the ratio of the micropore specific surface area is 75%, the ash content is 3.0wt%, and the pore volume is 0.5mL / g; the material of the activated carbon is coconut shell.

[0047] Measure 5mL of ethylene glycol and 160mL of 0.05g / mL alanine solution, stir evenly, then transfer to a hydrothermal reactor and keep at 250°C for 3h, then transfer the reaction solution to a dialysis bag with a molecular weight cut-off of 5000 Carry out dialysis for 12 hours; then freeze-dry the dialysate at a relative vacuum degree of <-0.085MPa and a temperature of -10°C for 10 hours to obtain solid powder of quantum dots.

[0048] Then weigh 5g of activated carbon, place it in 30mL of 9mol / L hydrochloric acid solution for 8 hours of impurity removal and pore expansion treatment, the treatment temperature is 40°C, then filter and wash until neutral, then add 25mL of water to mix and stir, and dr...

Embodiment 3

[0051] The physical parameters of the carrier activated carbon: the specific surface area is 1700m 2 / g, the ratio of the micropore specific surface area is 85%, the ash content is 3.0wt%, and the pore volume is 0.65mL / g; the material of the activated carbon is coconut shell.

[0052] Measure 5mL of ethylene glycol and 180mL of 0.165g / mL alanine solution, stir evenly, then transfer to a hydrothermal reactor and keep at 180°C for 6h, then transfer the reaction solution to a dialysis bag with a molecular weight cut-off of 5000 Carry out dialysis for 14 hours; then freeze-dry the dialysate at a relative vacuum degree of <-0.085 MPa and a temperature of -5°C for 12 hours to obtain solid powder of quantum dots.

[0053] Then weigh 5g of activated carbon, place it in 100mL of 8mol / L hydrochloric acid solution for 8 hours of impurity removal and pore expansion treatment, the treatment temperature is 60°C, then filter and wash until neutral, then add 30mL of water to mix and stir, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com