Roller type non-contact backstop

A non-contact, backstop technology, which is applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of high precision machining of wedges, large running resistance, and reduced service life of backstops, etc., and is easy to achieve Processing and measurement, improving life and performance, and ensuring the effect of precise consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

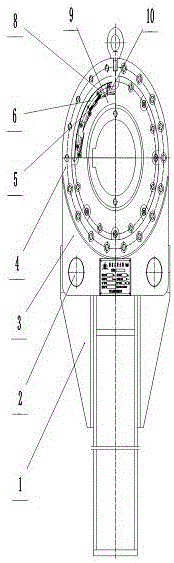

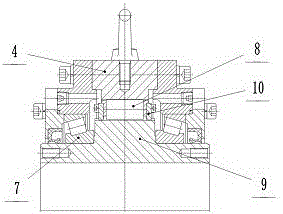

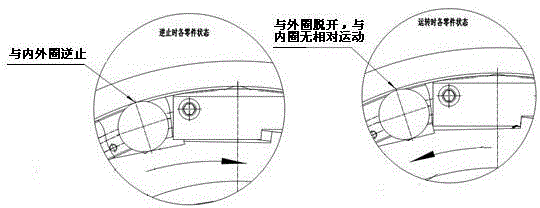

[0016] combined with figure 1 , attached figure 2 And attached image 3 To illustrate, the roller type non-contact backstop of the present invention consists of arm 1, bearing pin 2, side plate 3, outer ring 4, extension spring 5, cage 6, bearing 7, roller 8, inner ring 9 and The baffle plate 10 is composed of the arm 1 and the side plate 3 on the main body of the backstop through the pin shaft 2, the side plate 3 is connected with the outer ring 4, and the internal cage 6 is installed on the outer ring 4 and the inner ring 9 formed In the space, the inner ring 9 is installed on the shaft extension of the transmission device, and a plurality of backstop planes are evenly distributed on the inner ring 9, and the roller 8 is in contact with the outer ring 4, and is arranged in the space between the outer ring 4 and the inner ring 9 backstop planes. A plurality of rollers 8 are evenly positioned in the groove and through the cage 6, and the radial and axial movable spaces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com