Copper pipe side-by-side automatic bending device

A bending device and copper tube technology, applied in the field of pipe bending, can solve the problems of high labor intensity and affect production efficiency, and achieve the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

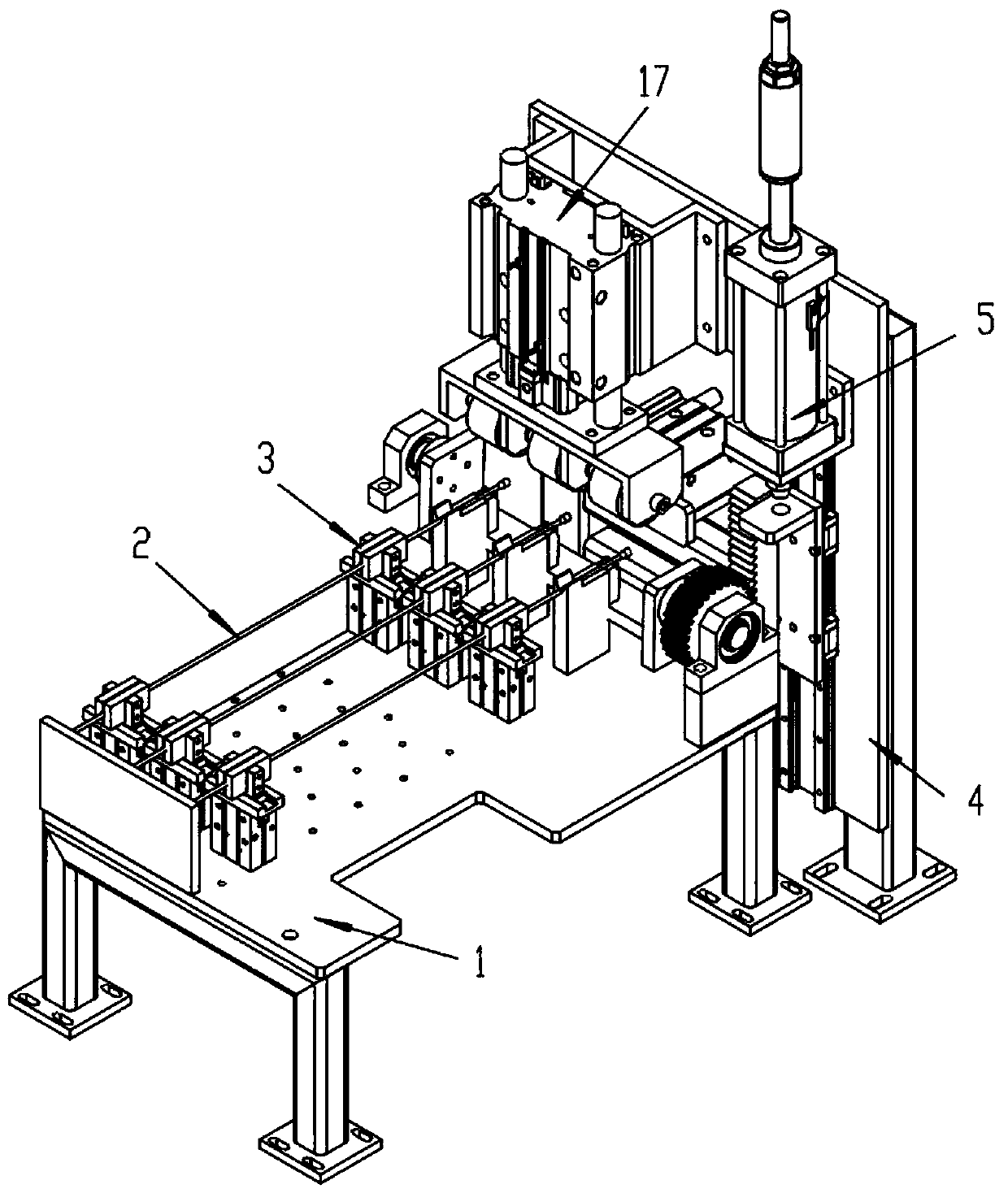

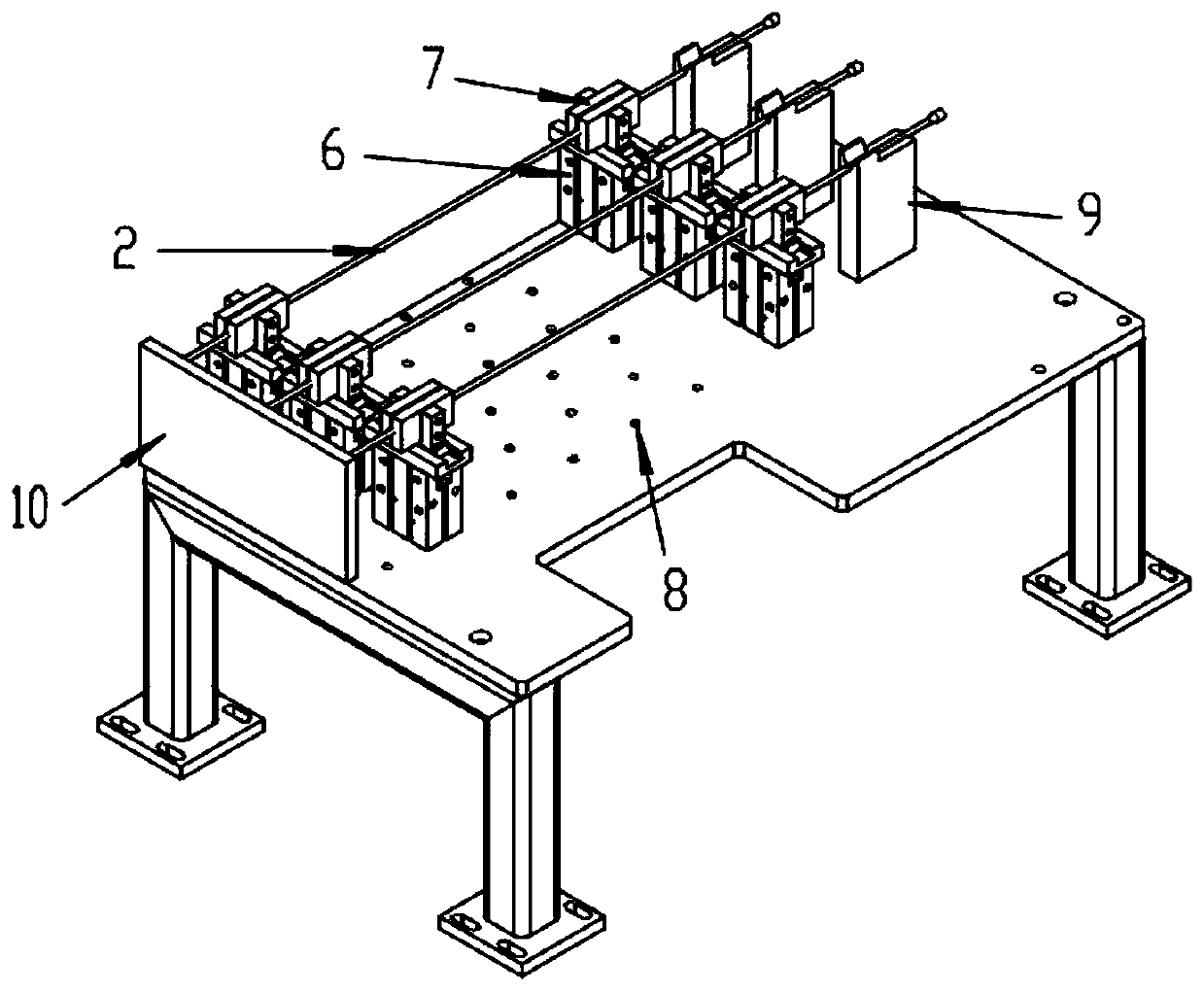

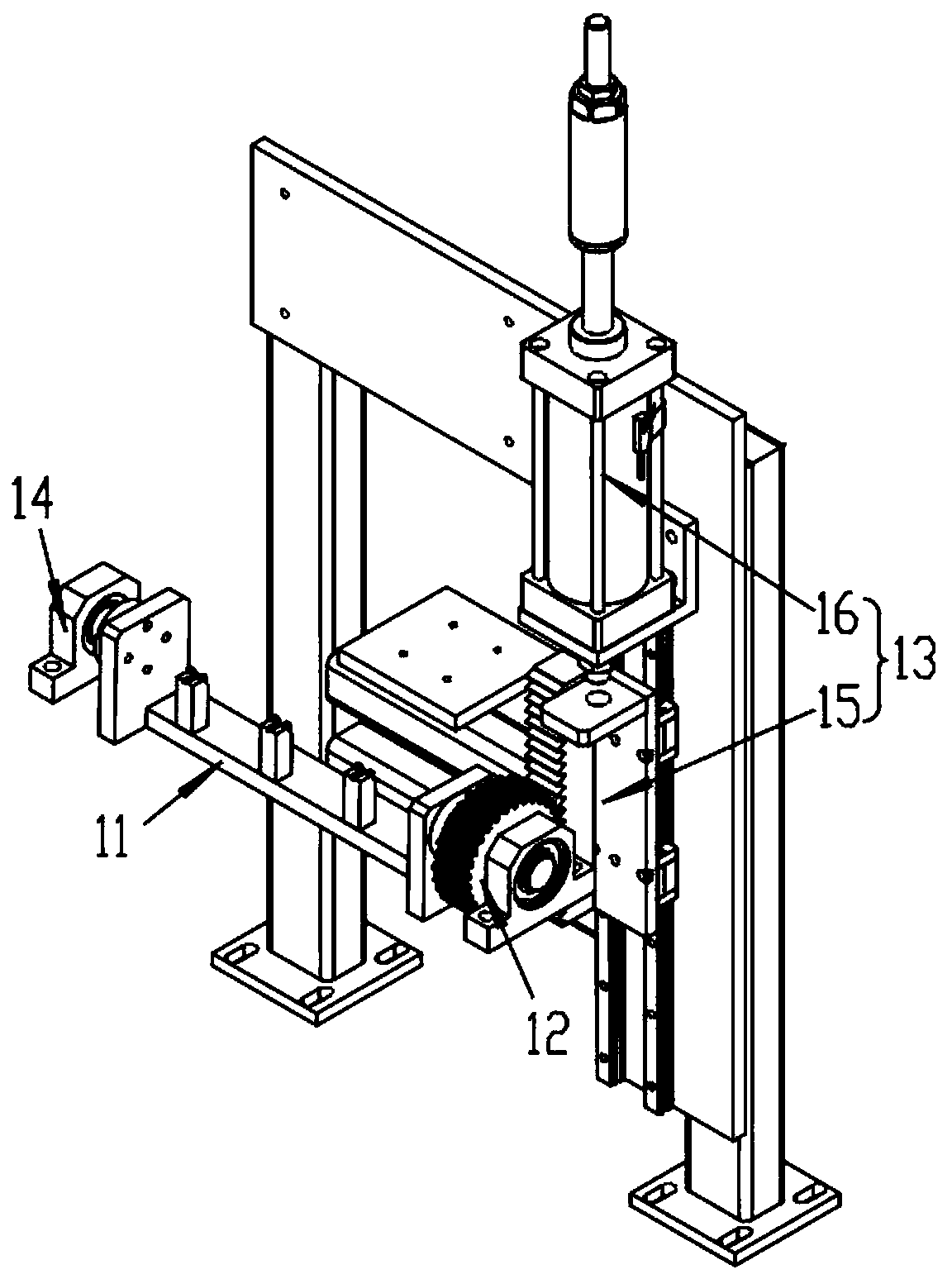

[0026] A kind of parallel automatic bending device for copper tubes of this embodiment, such as Figure 1-4 As shown, it includes a first mounting bracket 1, the top of the first mounting bracket 1 is fixed with an arrangement and positioning mechanism 3 for arranging and positioning a plurality of copper pipes 2, and the tail of the arrangement and positioning mechanism 3 is fixed with a second mounting bracket 4. The second mounting bracket 4 is fixed with an automatic bending mechanism 5 capable of adjusting the bending angles of multiple copper pipes 2 . The alignment and positioning of multiple copper tubes 2 is realized by arranging the positioning mechanism 3, which is convenient for the automatic bending mechanism 5 at the tail of the positioning mechanism 3 to perform automatic bending processing on multiple copper tubes 2 at the same time, realizing the simultaneous bending of multiple copper tubes 2 Bending processing, suitable for fast production rhythm and high ou...

Embodiment 2

[0038] The other structures of this embodiment are the same as those of Embodiment 1, except that the driving method of the rack assembly used in Embodiment 1 can be changed to an electric actuator to adapt to automatic switching and adjustment of the bending angle of the copper pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com