Illumination lamp and transparent part pressing plate thereof

A technology of transparent parts and pressing plates, which is applied to the components of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problem of high dimensional accuracy requirements for the processing of transparent parts pressing plates, and achieve the goal of reducing processing costs and reducing processing dimensional accuracy requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

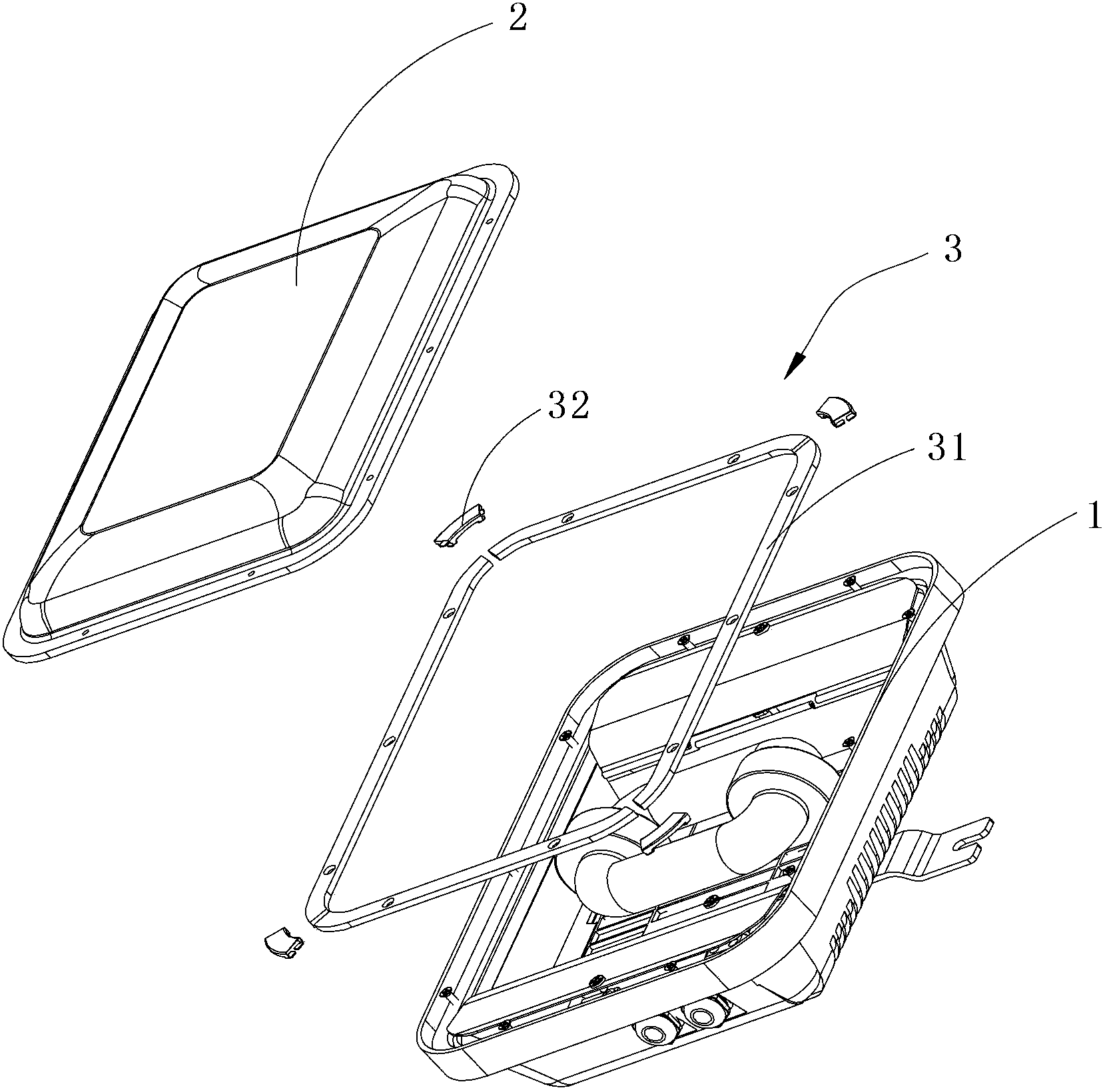

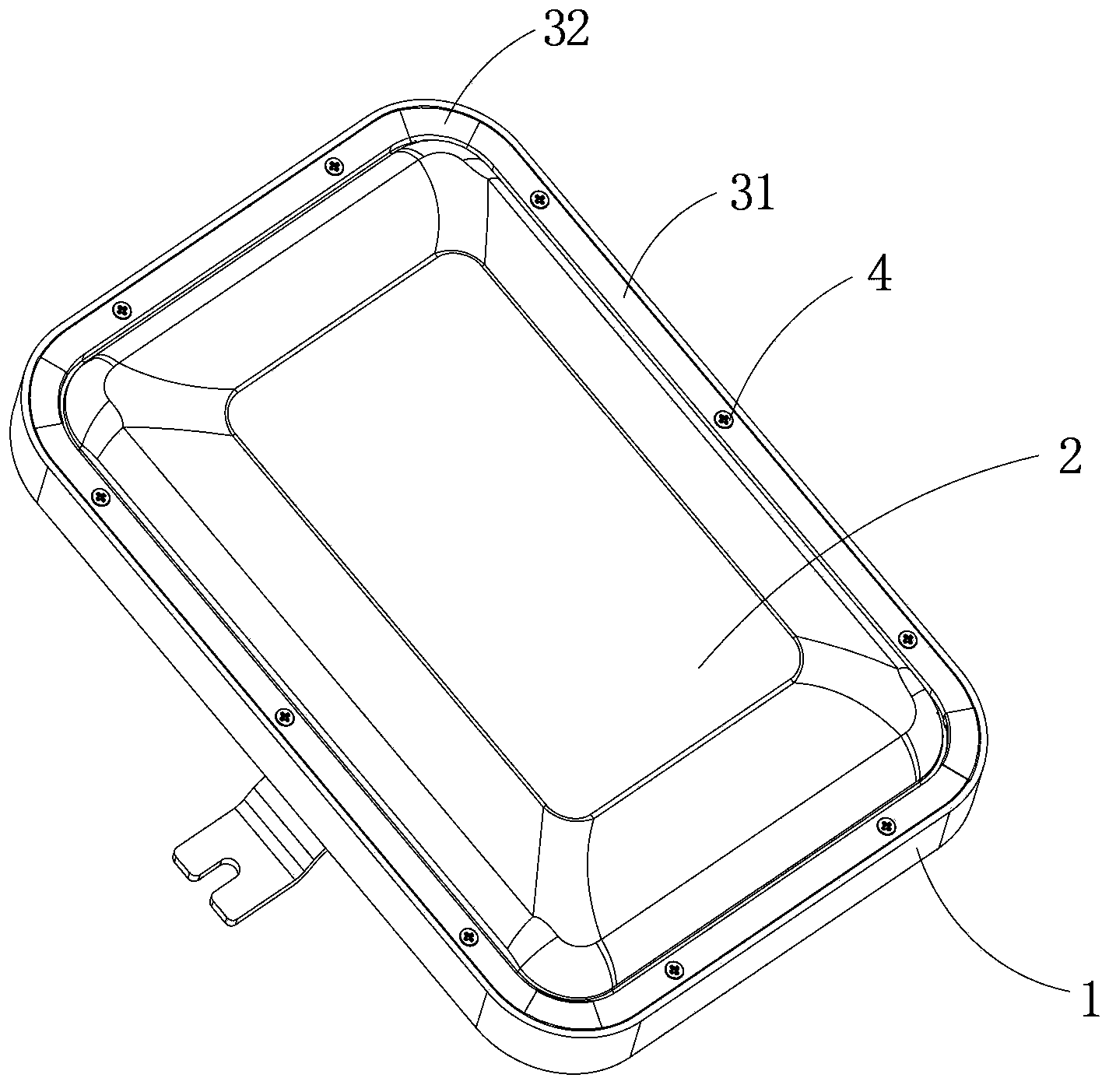

[0022] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

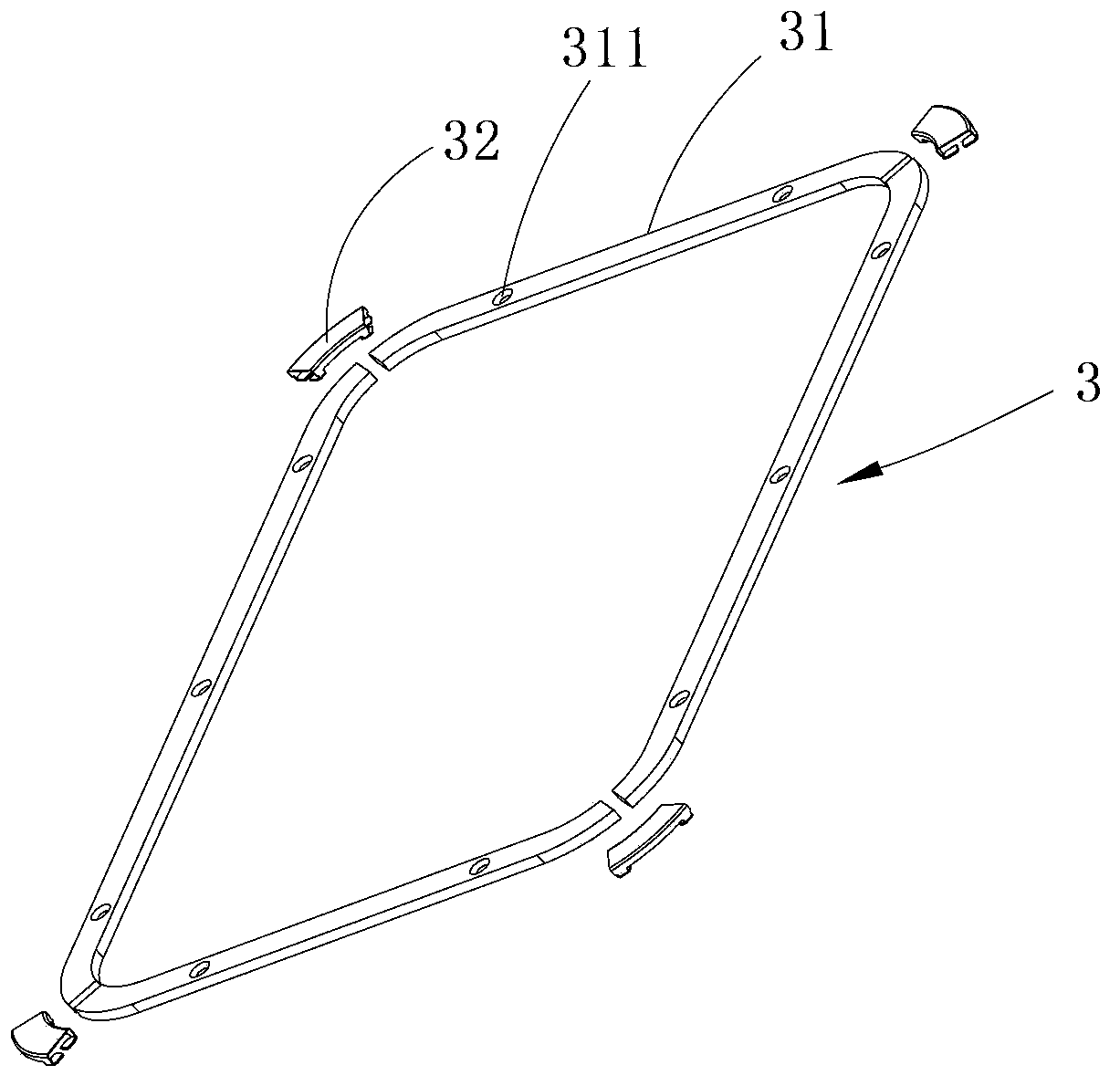

[0023] see figure 1 , the present embodiment provides a transparent member pressure plate 3, including a plurality of pressure strips 31 and connectors 32, the plurality of pressure strips 31 are sequentially connected end to end to form a frame shape, and the ends of two adjacent pressure strips 31 extend into the same connector 32, and the bead 31 has a movable gap in the connecting member 32 in the length extension direction and the width direction. The transparent member pressing plate 3 can be applied in lighting fixtures, and is used to prevent gaps from being formed when the transparent member is pressed together with the lamp body to avoid light leakage. The bead 31 is provided with an installation hole 311, and the installation hole 311 is used for coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com