Weighing system and anti-cheating method and device for weighing system

A weighing system and anti-cheating technology, applied in the weighing field, can solve the problems of tampering with the weighing data on the display side or the instrument side, and achieve the effect of increasing cost, wide application and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

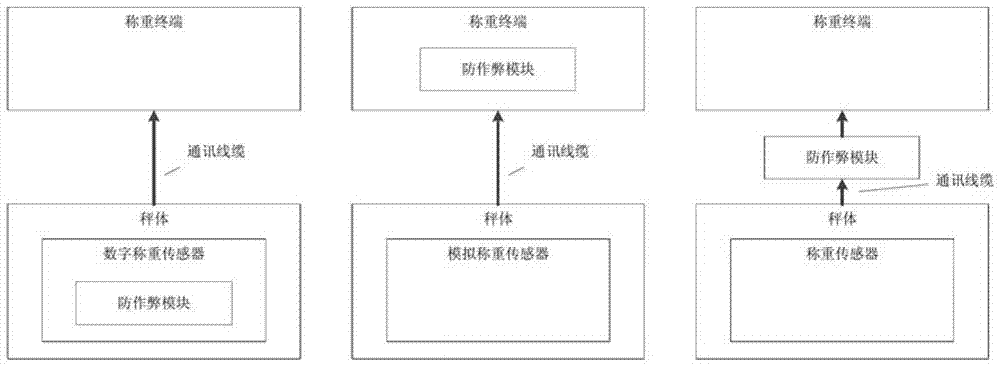

[0083] Example 1: Application of Vehicle Scale Digital Weighing System

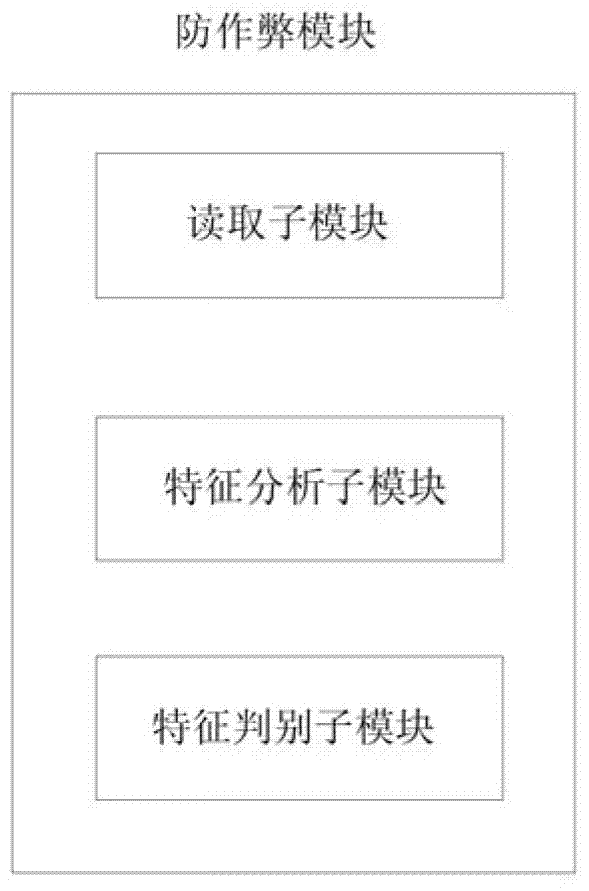

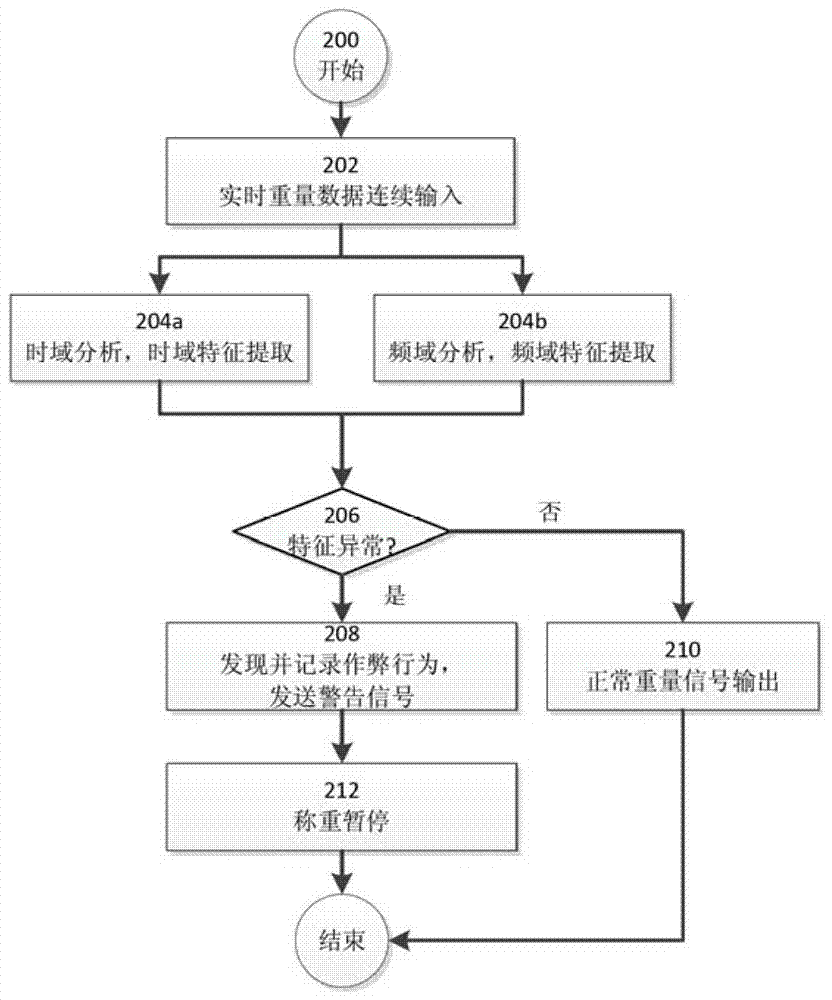

[0084] see Figure 5 , The vehicle scale digital weighing system is mainly composed of a scale body 3, 8 digital load cells 1, a communication cable 4 and a weighing instrument 2. Each digital load cell 1 includes an anti-cheating module 5 . This weighing system uses the bus communication protocol, chain network connection, no junction box. The scale body 3 is a weighing carrier. When the vehicle stops or slowly drives through the scale body 3, the weight of the vehicle and goods is directly loaded on the scale body 3. Eight digital weighing sensors 1 are installed in the scale body 3 to collect vehicle weight signals respectively. The initial analog weighing signal is converted by A / D and converted into a stable noise-free digital weighing signal after digital signal processing; The weighing signal enters the anti-cheating module 5 to determine whether the weighing signal contains a cheating signal. I...

Embodiment 2

[0105] Example 2: Application of Platform Scale Analog Weighing System

[0106] see Figure 8 , The platform scale weighing system is mainly composed of a scale body 3, 4 analog load cells 1, an analog junction box 6, a communication cable 4, an anti-cheating module 5 and a weighing instrument 2. The anti-cheating module 5 is embedded in the weighing instrument 2 . Four analog load cells 1 are physically installed in the scale body 3 to collect weight signals respectively. The analog junction box 6 summarizes the signals from the four analog load cells 1, and sends the summarized analog signals to the weighing instrument 2, and the weighing instrument 2 performs analog-to-digital conversion on the collected analog signals and converts them into digital signals , the digital signal is converted into a stable noise-free digital weighing signal after digital processing such as digital filtering; the weighing signal after digital signal processing enters the anti-cheating module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com