Tread assembly charging system

A tread and component technology, applied in the field of radial tire manufacturing, can solve the problems of long feeding cycle, high cost of feeding system, long time required, etc., and achieve the effect of saving equipment cost, low cost and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

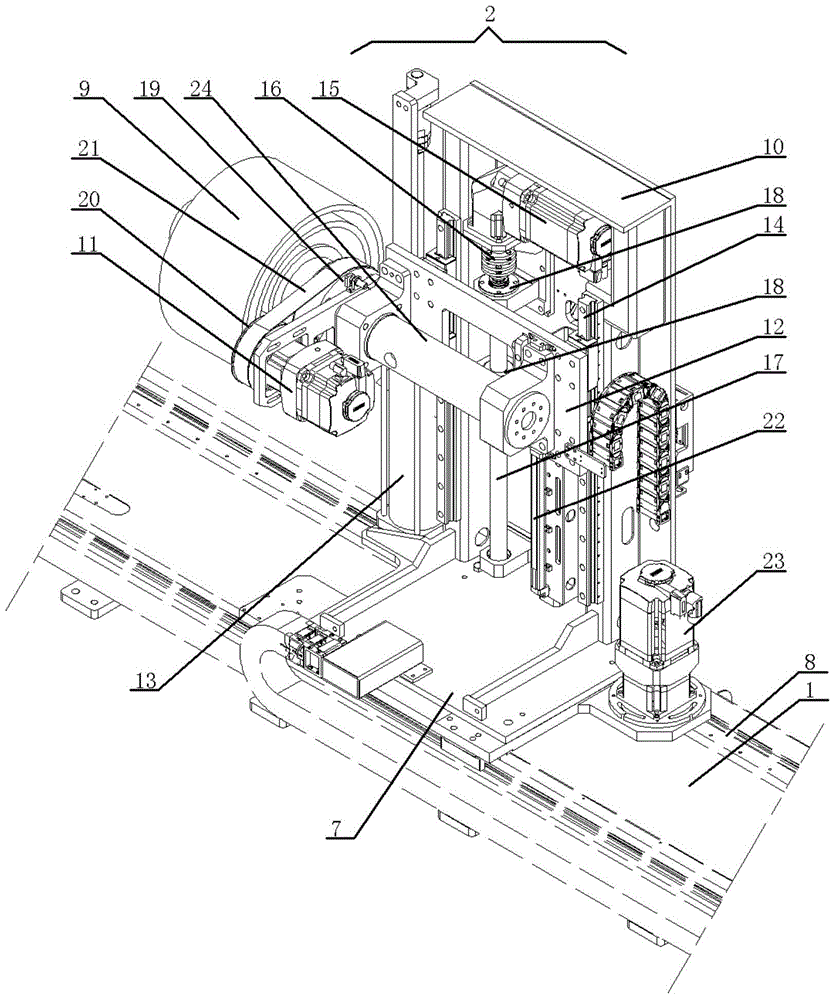

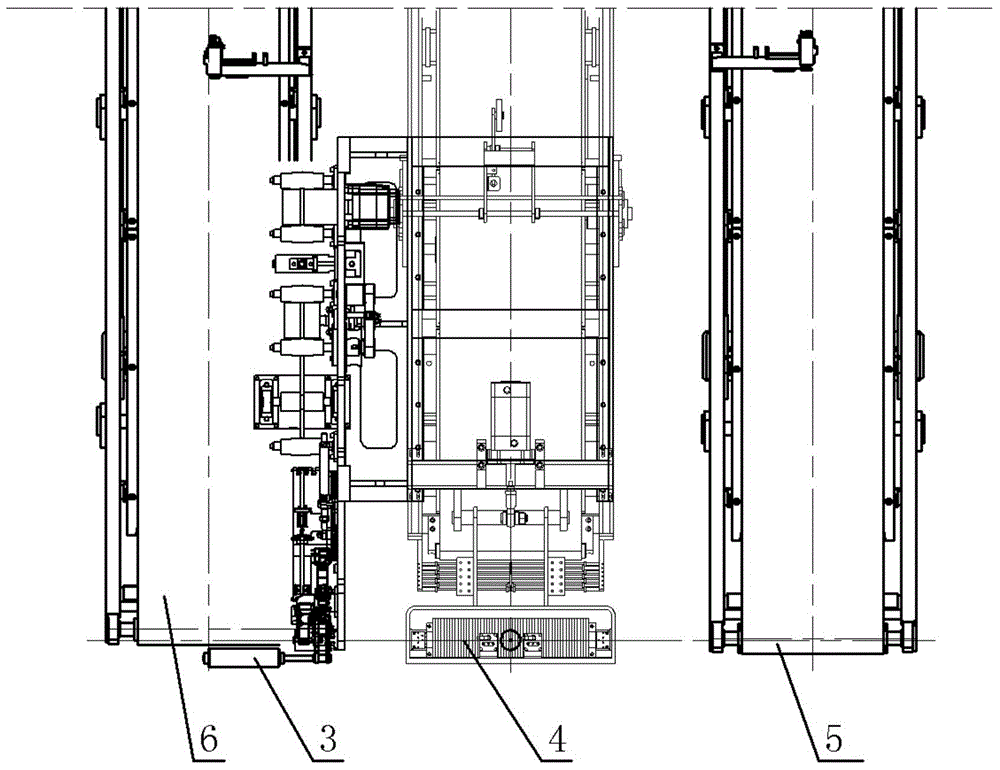

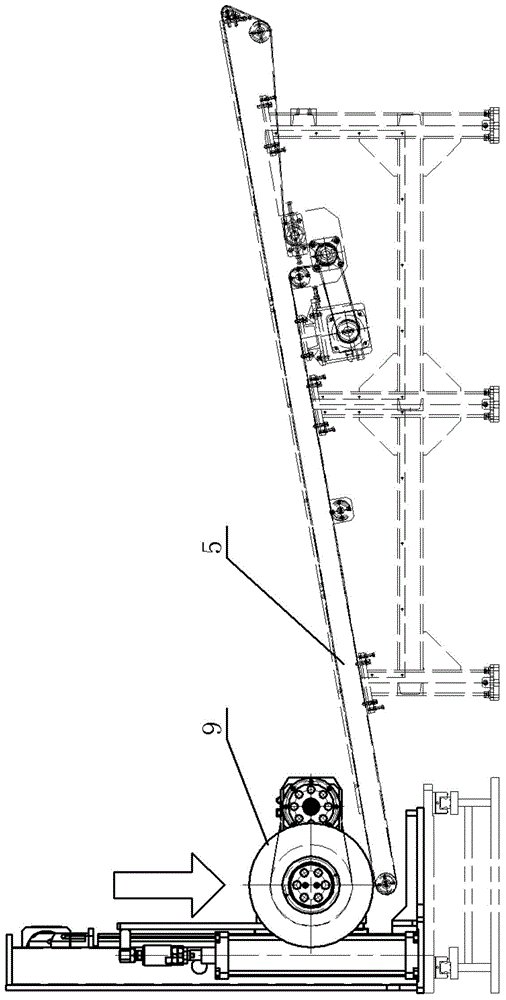

[0019] A tread assembly feeding system, see Figure 1 to Figure 6 : It includes a base 1, on which a belt drum structure 2 that can move horizontally and linearly is arranged, and one side of the base 1 is respectively arranged with a belt layer feeding template, a crown belt template 3, and a tread feeding template 4, The belt layer feeding template includes 1# belt layer feeding template 5, 2# belt layer feeding template 6, the horizontal moving slide plate 7 of the belt drum structure 2 is supported on the horizontal linear guide rail 8 of the base 1, and the belt drum The belt drum 9 in structure 2 is externally connected with a vertical drive device, and the vertical drive device is arranged on the vertical support 10 of the belt drum structure 3. The bottom of the vertical support 10 is fastened to the horizontally moving slide plate 7, and the belt drum rotates. The drive motor 11 drives the belt drum 9 to rotate.

[0020] The belt drum structure 2 specifically include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com