Rail transport device of car shell

A technology of rail transportation and car shell, which is applied in transportation and packaging, transportation of passenger cars, motor vehicles, etc., can solve problems such as unfavorable safety production, track length, height difference, etc., and achieve the effect of saving capital investment and saving workshop space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

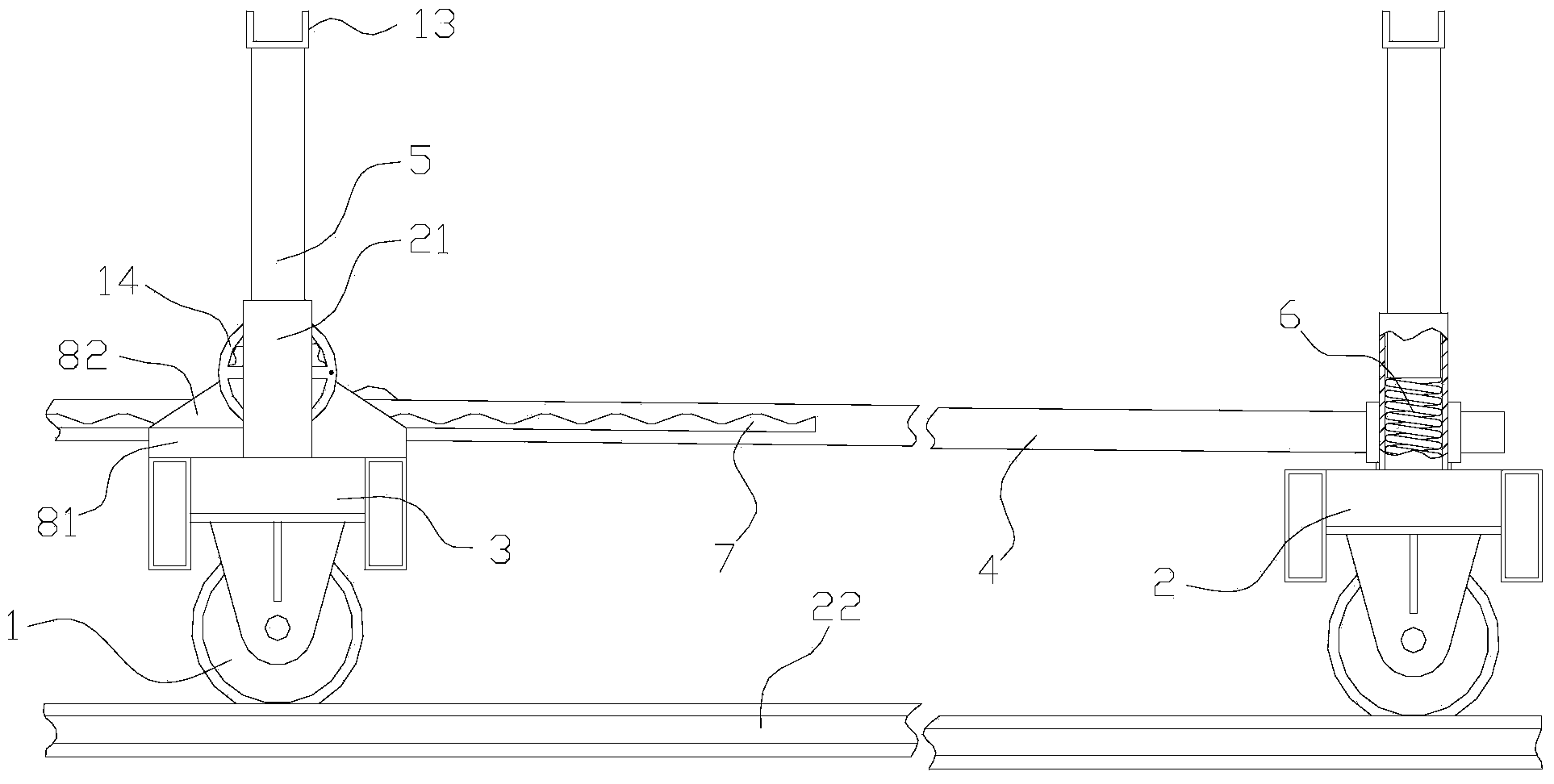

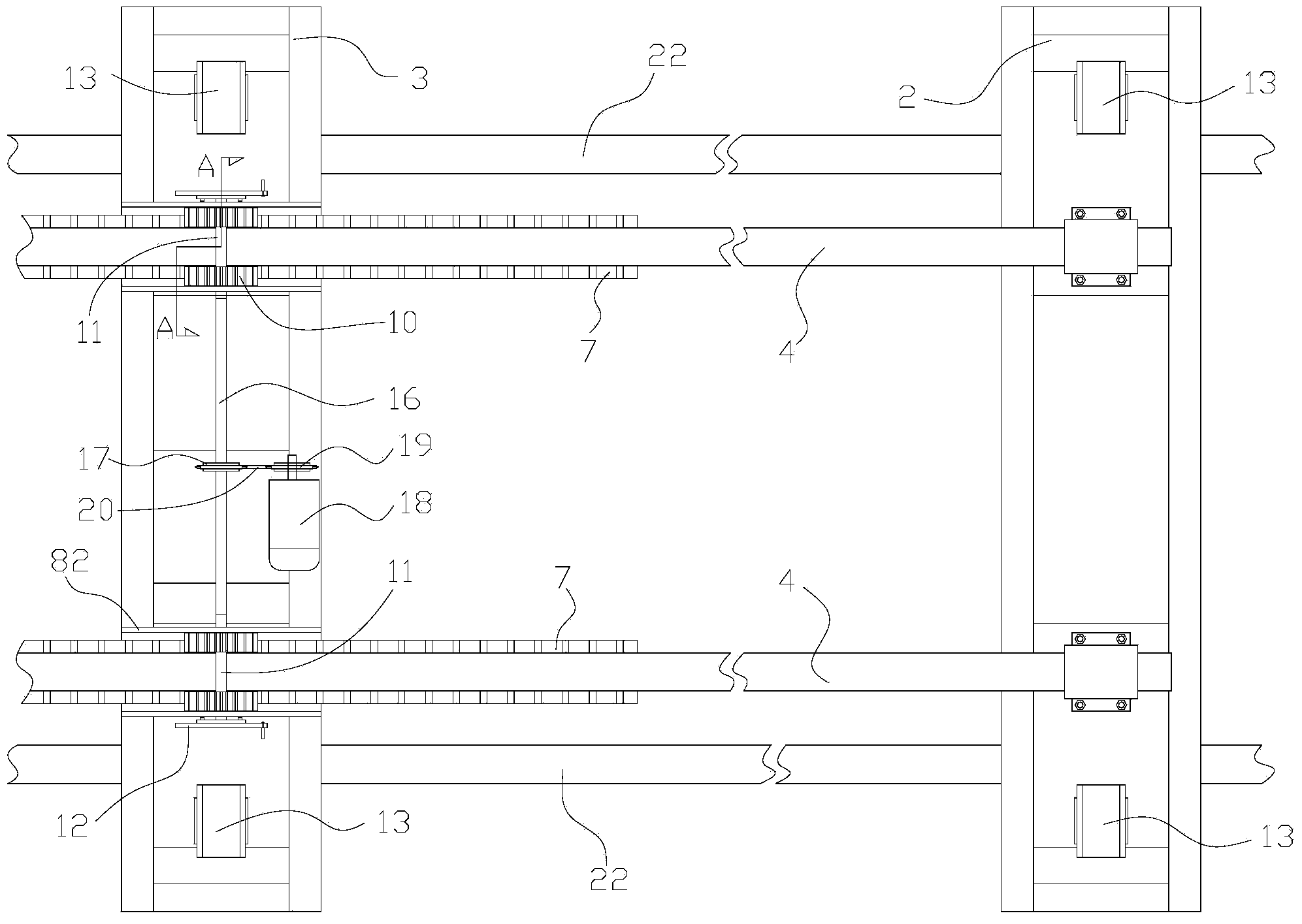

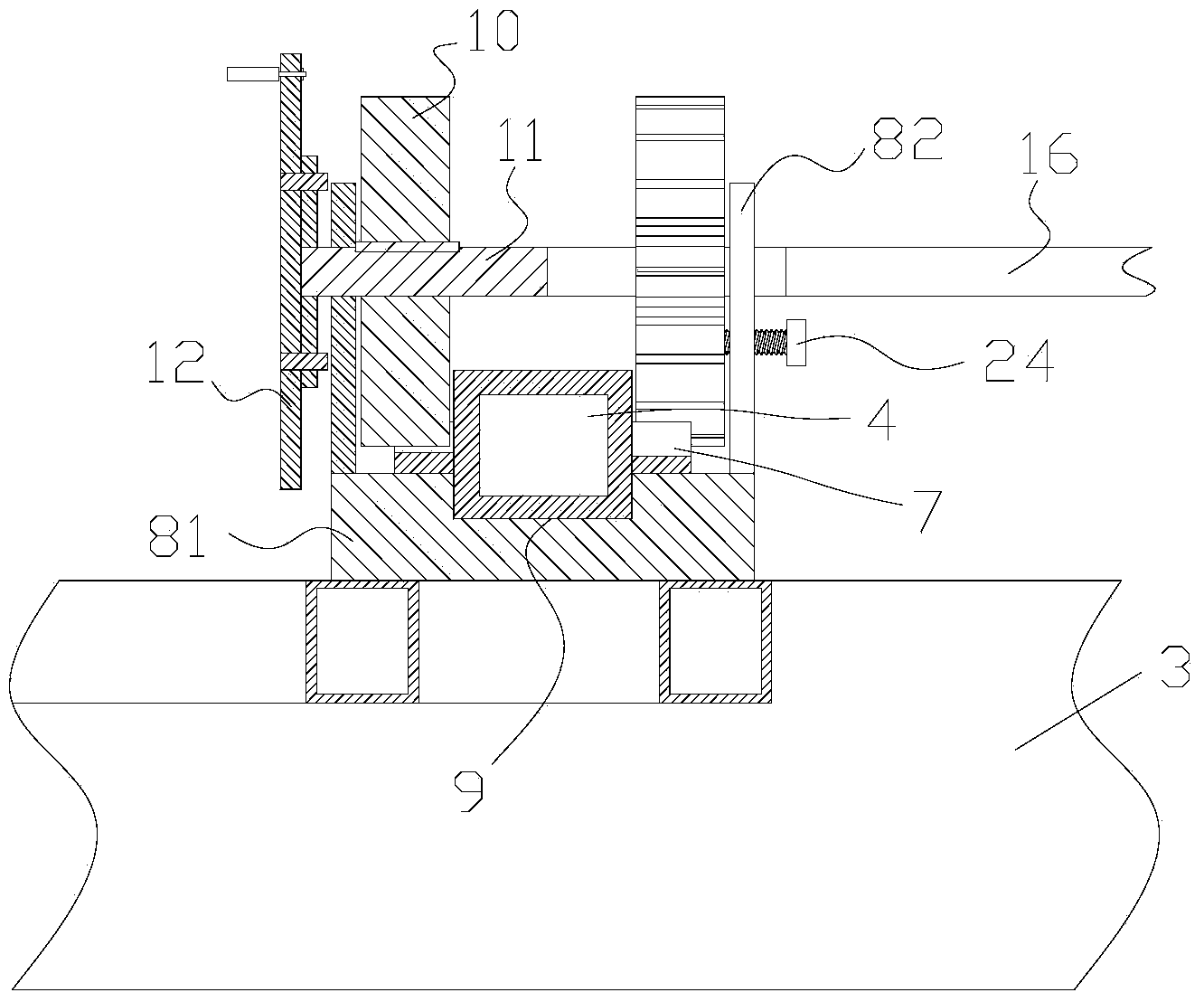

[0026] Figure 6 It is the second specific embodiment of the present invention. As shown in the figure, an automobile body rail transport device includes a front wheel frame 2 and a rear wheel frame 3 arranged along the direction of the track 22 and at least one connecting front wheel frame 2 And the balance bar 4 with elastic deformation of the rear wheel frame 3, the bottom of the front wheel frame 2 and the rear wheel frame 3 are respectively slid up and down to be provided with two wheel brackets 23 corresponding to the two rails 22, the bottom of the wheel bracket 23 The T-shaped wheels 1 that are respectively matched with the corresponding rails 22 are rotatably connected; the upper planes of the two wheel brackets 23 at the bottom of the front wheel frame 2 are respectively vertically provided with a support column that passes through the upper plane of the front wheel frame 2 upwards. 5. The upper planes of the two wheel brackets 23 at the bottom of the rear wheel fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com