Reconfigurable fixture for sheet metal parts and method

A technology for metal parts and fixtures, applied in the field of reconfigurable fixtures, can solve the problems of prolonged development time, capital investment, large manufacturing area of fixtures, etc., so as to reduce development time, reduce manufacturing space, and reduce capital effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

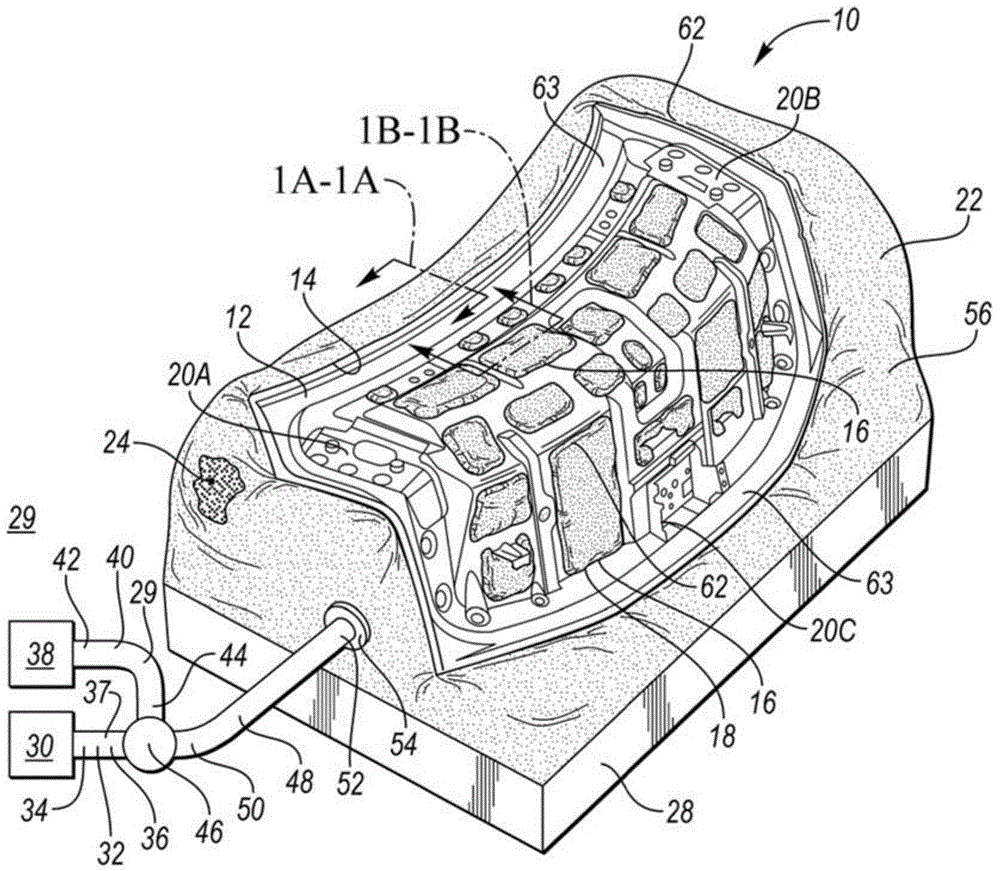

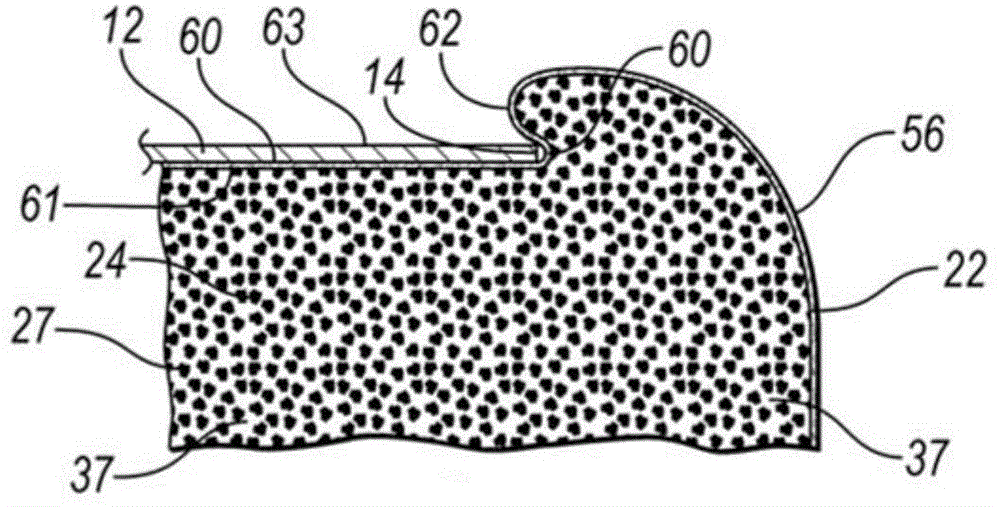

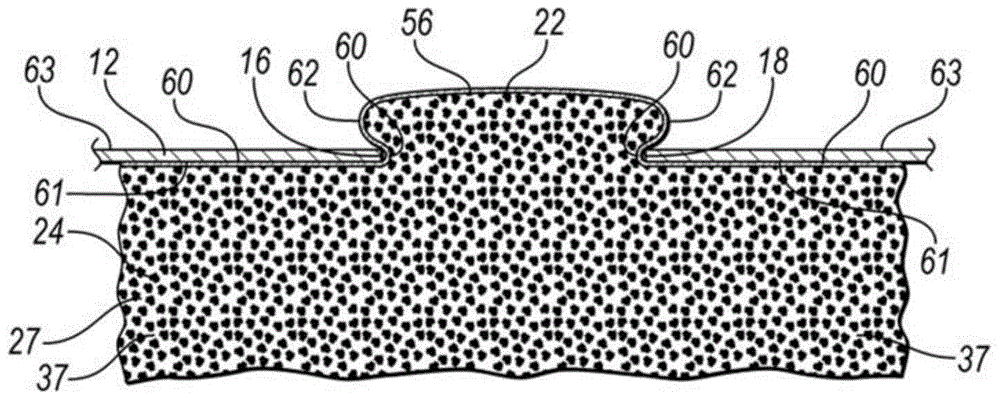

[0069] Referring to the drawings, wherein like reference numerals denote like parts, figure 1 A reconfigurable fixation device 10 for holding a component 12 is shown. Part 12 may be a sheet metal part, such as a decklid inner panel, as shown. Part 12 may be made of steel, aluminum or any other suitable sheet metal, or may be made of any other suitable metallic or non-metallic material. A component or sheet metal part 12 may be held by the reconfigurable fixture 10 for handling, assembly or inspection. A number of subcomponents 20A, 20B, 20C are shown, which may be reinforcements for the sheet metal component 12 . The subcomponents 20A, 20B, 20C may be positioned for assembly to the sheet metal part 12 or may be already assembled to the sheet metal part 12 . Assembly may include welding, fastening, snap-fitting, or any other suitable method of attachment. Processing may include forming, stamping, cutting, grinding, polishing or any other part process. Inspection may includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com