Cable drum rack

A technology for cables and racks, applied in the field of cable production equipment, can solve the problems of low efficiency, hidden dangers, low driving efficiency, etc., and achieve the effects of eliminating hidden dangers, improving efficiency, and having a wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

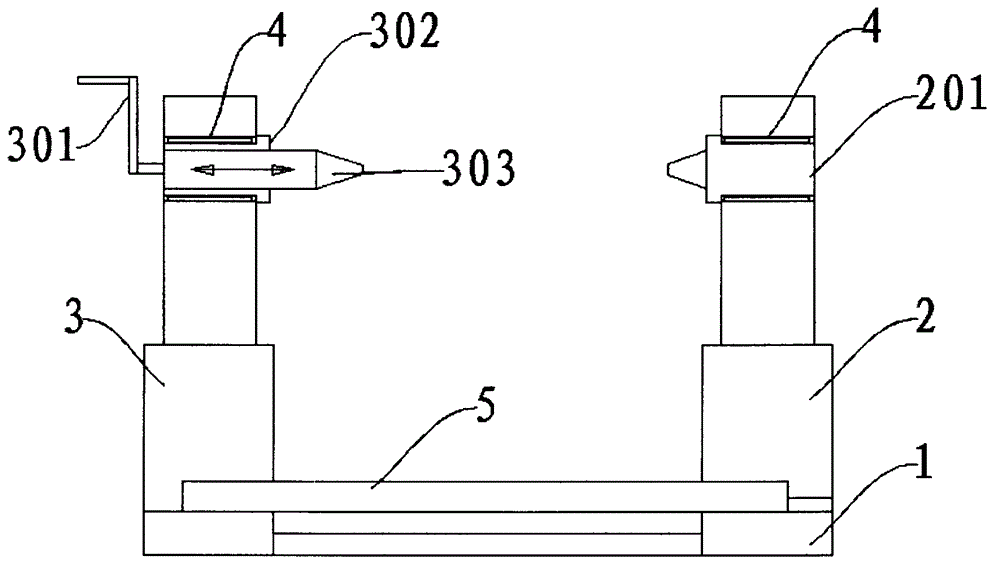

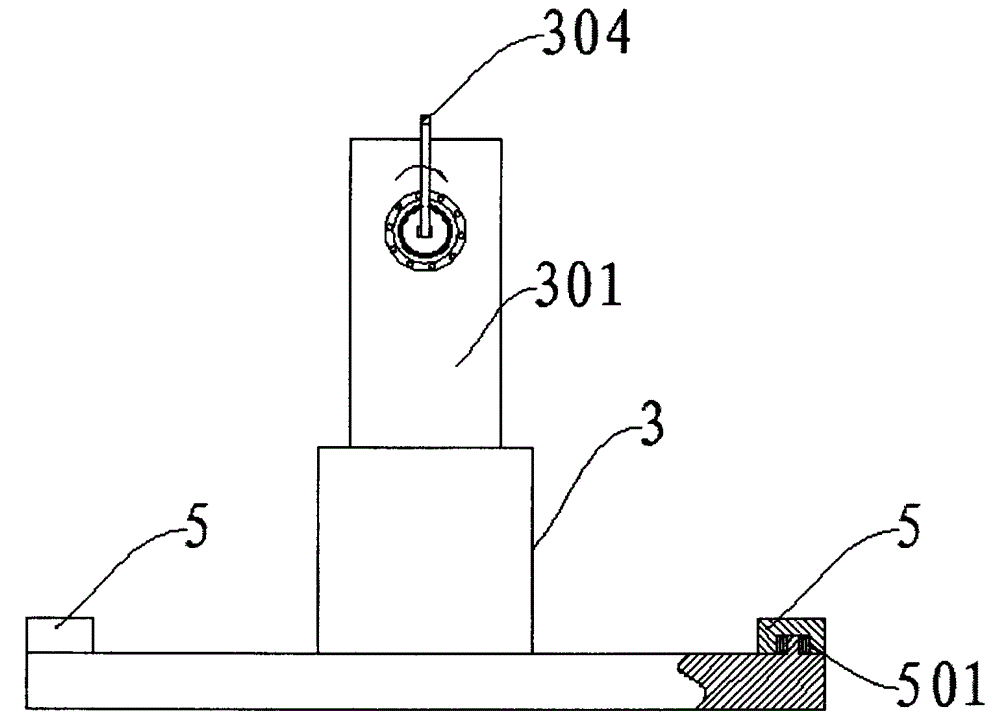

[0014] Referring to the accompanying drawings, a cable reel frame includes a bottom plate 1 and a supporting structure, the supporting structure includes a hydraulic cylinder 1 3 and a hydraulic cylinder 2 2, the top of the hydraulic cylinder 1 3 is equipped with a rotating sleeve 302 through a bearing 4, The inside of the rotating sleeve 302 is threaded with a top cone 1 303, and the top of the hydraulic cylinder 2 2 is equipped with a top cone 2 201 through a bearing 4, and the top of the top cone 1 301 is opposite to the top of the top cone 2 201; The end of said top cone one 301 is provided with a rotating handle 301 or a rotating motor; said bottom plate 1 is two pieces, and the middle is connected by a number of connecting and fixing plates 5; said connecting and fixing plates 5 have two pieces, one It is fixed on the bottom plate by welding, and one end of the other connecting fixed plate is connected to the bottom plate through a bearing 501, and the other end is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com