Liquid Zinc Corrosion Resistant Alloy Inner Heater

An internal heater and zinc corrosion technology, which is applied in the field of liquid zinc corrosion-resistant alloy internal heaters, can solve the problems of difficult large-scale industrial production, low thermal efficiency, and low service life, and achieve good thermal conductivity, fast heat transfer speed, and high temperature uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

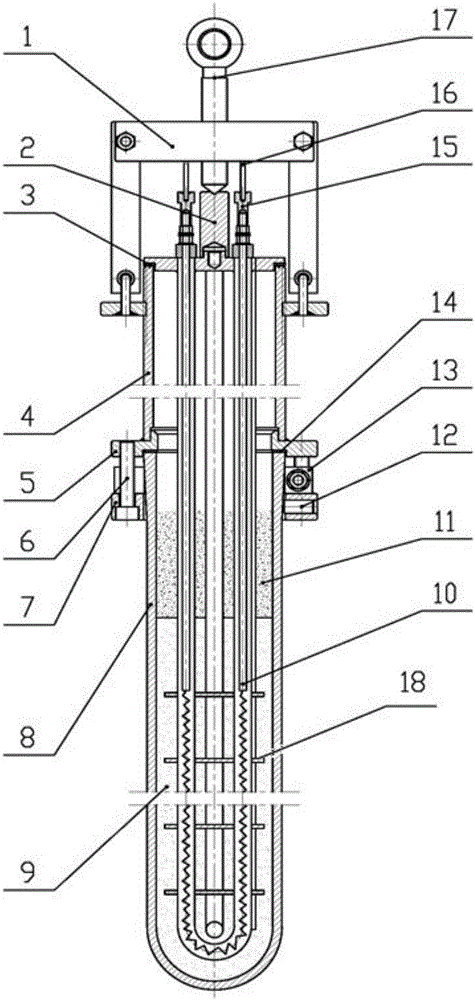

[0022] In this embodiment, the above-mentioned connection method is used for connection. The outer sleeve 8 is made of tungsten-molybdenum alloy, wherein the mass fraction of tungsten is 20%, and the mass fraction of molybdenum is 80%. ℃, the electric heating core 10 adopts a U-shaped electric heating tube, the number of metal plates in the heating area of the electric heating core 10 is 6, the distance between the plates is 30mm, the diameter of the metal plate is 40mm, and the thickness is 2mm; the electric heating core The length of the heating area of 10 is 200mm, the total length of the electric heating core 10 is 400mm; the outer diameter of the outer sleeve 8 is 60mm, the wall thickness is 5mm, and the length is 300mm, and the outer diameter of the extension tube 4 is 60mm, and the wall thickness is 5mm , the length is 150 mm, the outer diameter of the first connecting flange 5 and the second connecting flange 7 is 100 mm, and the thickness is 10 mm.

Embodiment 2

[0024] In this embodiment, the above-mentioned connection method is used for connection. The outer sleeve 8 is made of tungsten-molybdenum alloy, wherein the mass fraction of tungsten is 30%, and the mass fraction of molybdenum is 70%. The heat conductor 9 is a low melting point alloy with a melting point of 200-300 ℃, the electric heating core 10 is composed of 3 sets of U-shaped electric heating tubes, the number of metal plates in the heating area of the electric heating core 10 is 13, the distance between the metal plates is 70 mm, the diameter of the metal plates is 100 mm, and the thickness is 6 mm The length of the heating zone of the electric heating core 10 is 988mm, and the total length of the electric heating core 10 is 1450mm; the outer diameter of the outer sleeve 8 is 150mm, the wall thickness is 20mm, and the length is 1200mm, and the outer diameter of the long pipe 4 is 150mm, The wall thickness is 20mm, the length is 300mm, the outer diameter of the first con...

Embodiment 3

[0026]In this embodiment, the above-mentioned connection method is used for connection. The outer sleeve 8 is made of tungsten-molybdenum alloy, wherein the mass fraction of tungsten is 40%, and the mass fraction of molybdenum is 60%. The heat conductor 9 is a low melting point metal with a melting point of 300-400 ℃, the electric heating core 10 is composed of 6 sets of U-shaped electric heating tubes, the number of metal plates in the heating area of the electric heating core 10 is 14, the distance between the metal plates is 100 mm, the diameter of the metal plates is 190 mm, and the thickness is 10 mm The length of the heating area of the electric heating core 10 is 1600mm, and the total length of the electric heating core 10 is 2150mm; the outer diameter of the outer sleeve 8 is 300mm, the wall thickness is 50mm, and the length is 1700mm, and the outer diameter of the extension tube 4 is 300mm, the wall thickness is 50mm, and the length is 500mm. The outer diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com