Automatic mouth glue attachment system

A fully-automatic technology for glue, which is applied in the field of mechanical products, can solve the problems of efficiency caused by the glue-shaped tape, and achieve the effect of simple structure, high efficiency and meeting the needs of film sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] like Figure 1-12 shown.

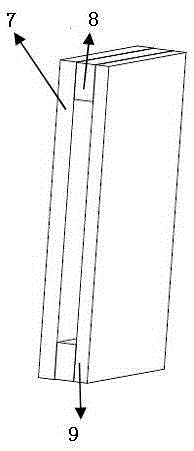

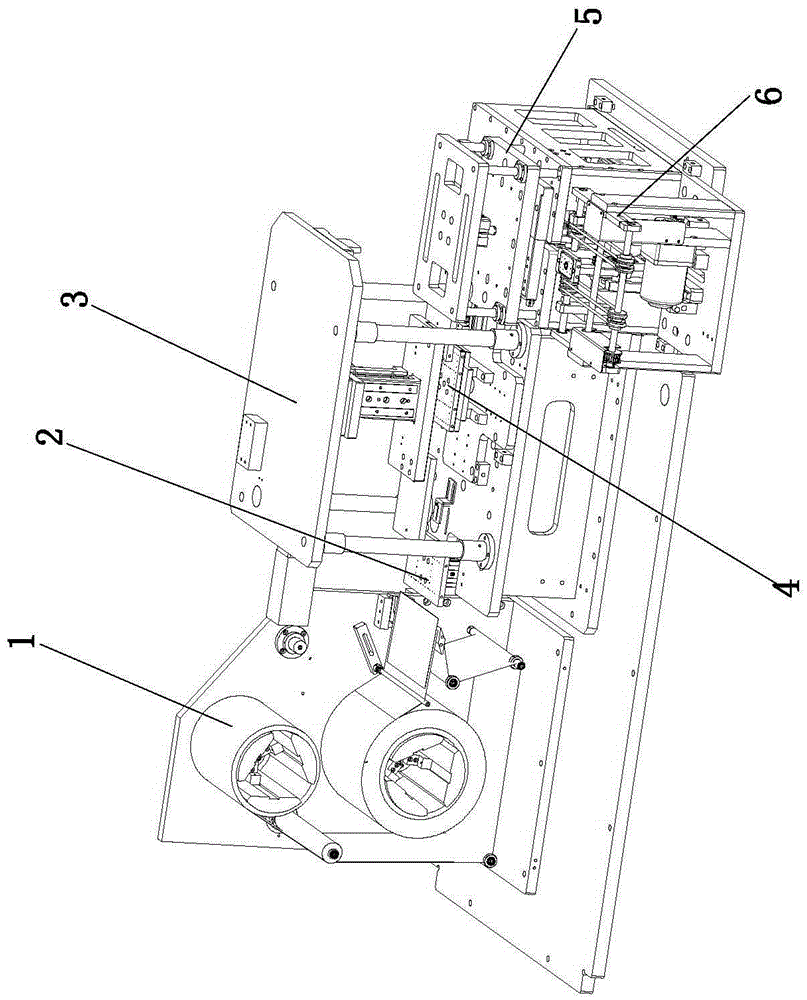

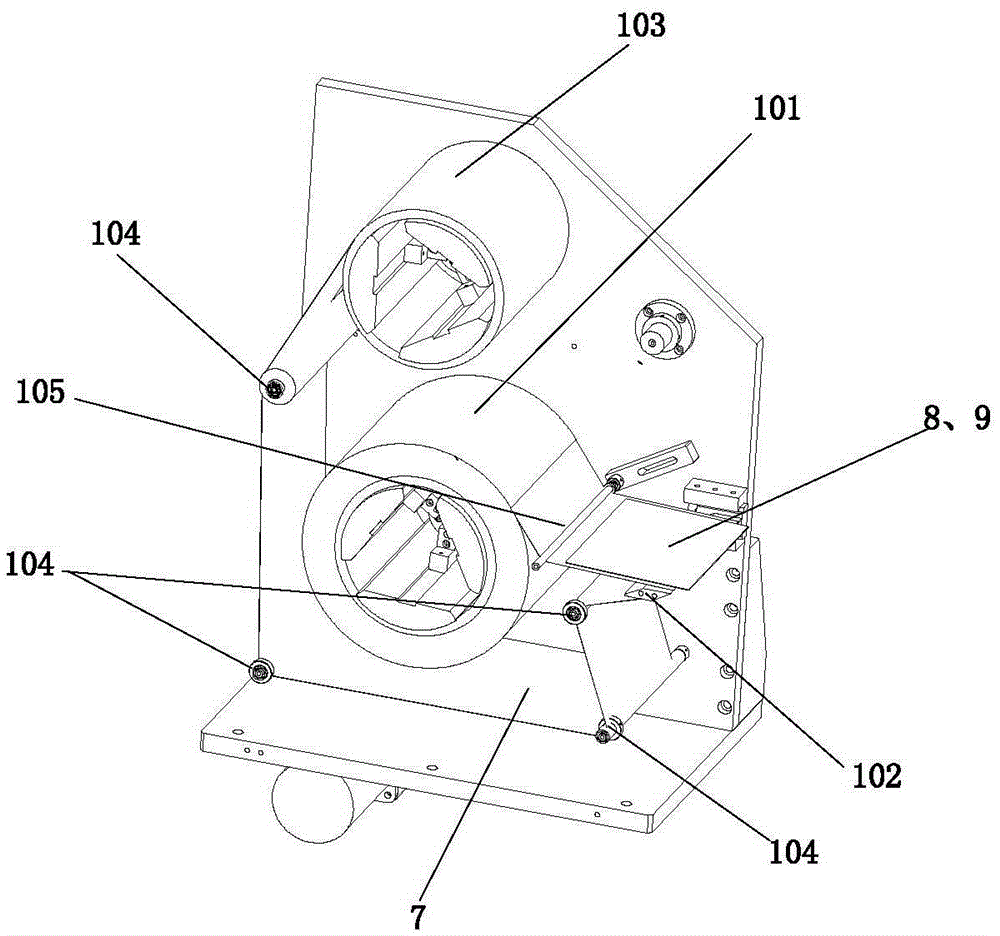

[0036] A fully automatic mouth glue attachment system, its overall shape and structure are as follows Figure 12 As shown, the structure of its internal overall working part is as follows figure 2 , mainly including a tape feeding primary separation mechanism 1, a tape separation mechanism 2, a tape transplanting mechanism 3, a tape alignment mechanism 4 and a glue pressing mechanism 5. Adhesive tape feeding primary separation mechanism 1 is used to separate the slit-shaped adhesive tape 8 adhering to the receiving film 7 together with the release line 9 from the receiving film 7 to form a slit-shaped adhesive tape unit for attachment ( figure 1 ), the tape feeding primary separation mechanism 1 can be designed by itself according to the needs, and can also be used image 3 As shown in the structure, the adhesive t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap