Piston rod type hydraulic cylinder structure

A piston rod and hydraulic cylinder technology, applied in the field of piston rod hydraulic cylinder structure, can solve the problems of inability to complete the required tasks and single structural form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

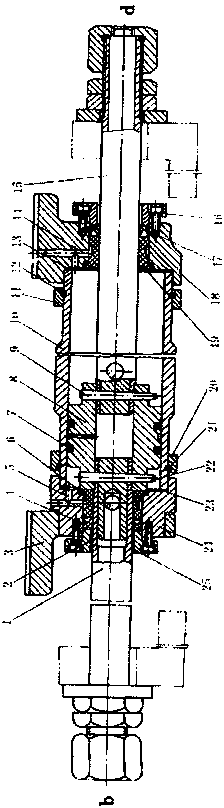

[0013] Such as figure 1 As shown, a piston rod type hydraulic cylinder structure, the hydraulic cylinder structure includes a piston rod 1, a bracket, an exhaust hole 5, a guide sleeve 6, a piston 8, a taper pin 9, a cylinder 10, a pressure plate 11, a wire ring 12. Gland 16, cylinder head 18, guide sleeve 6, gland 25, the piston rod is connected to the piston 8, the piston 8 is placed in the cylinder 10, the piston rod extends out of the cylinder, and the two ports of the cylinder are connected to the cylinder Cover, the piston rod is a split structure, two piston rods, piston rod 1 and piston rod 15, each of the two ends of the piston 8 is connected to a piston rod, and the connection modes of piston rod 1 and piston rod 15 to the piston are uniform. It is radially connected with a tapered pin 22; the piston rod 1 and the piston rod 15 are hollow rods, and the piston rod 1 and the piston rod 15 are provided with radial holes adjacent to the piston end for hydraulic oil to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com