Machining method of Y-shaped pipe with lug boss

A processing method, the technology of Y-shaped pipes, which is applied in the field of pipe processing, can solve the problems of thinning pipe fittings, low pass rate, defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

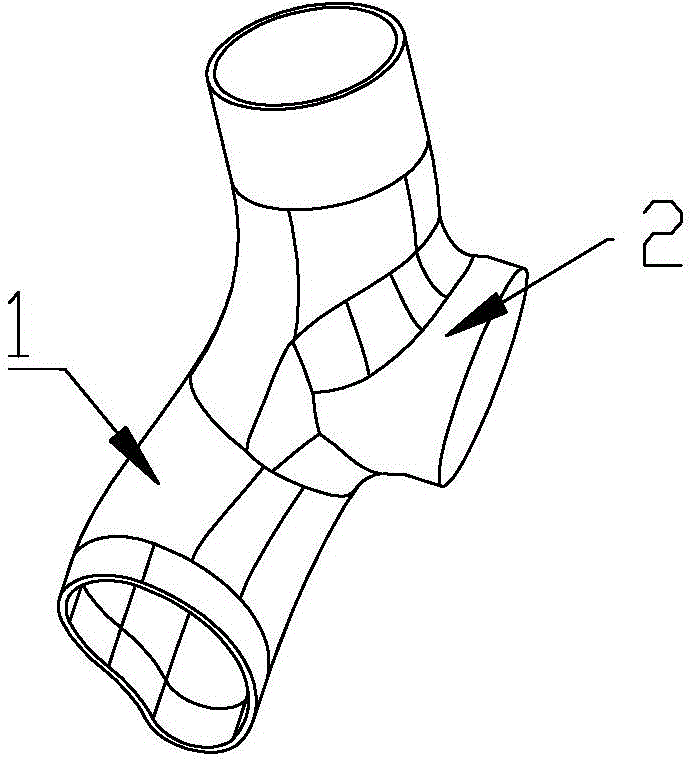

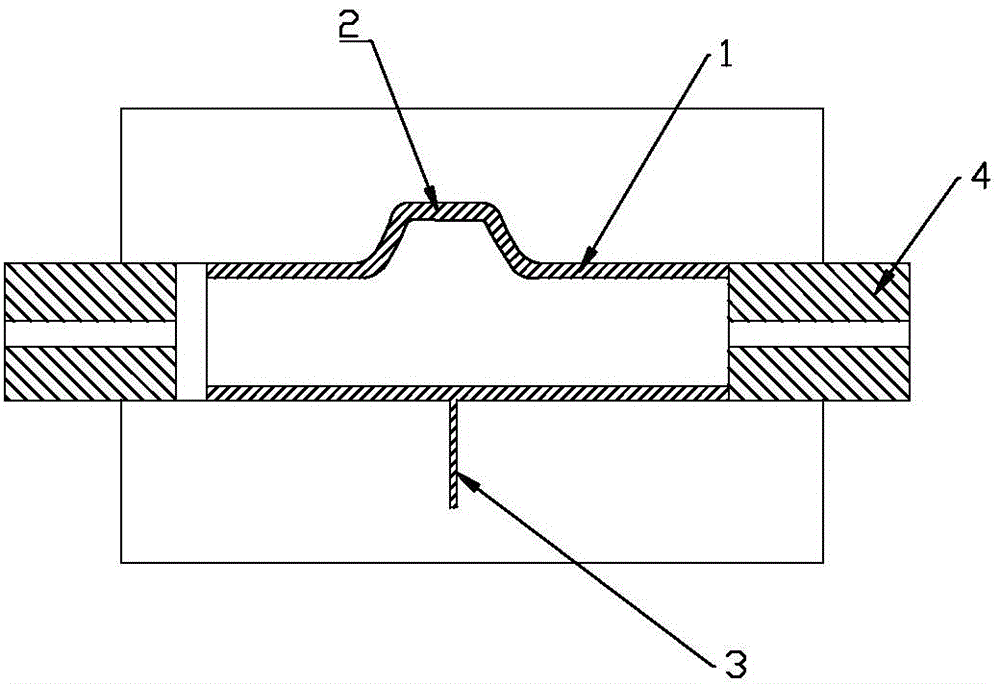

[0019] Such as figure 1 figure 2 Shown, the present invention provides a kind of processing method with the Y-type pipe of boss, and it comprises the following steps:

[0020] a. A flat storage bin 3 is provided on the opposite side of the boss 2 of the mould, the storage bin 3 communicates with the inner cavity of the mould, and the thickness of the storage bin 3 is smaller than the thickness of the pipe fitting 1;

[0021] b. Put the tube blank into the mold, and seal the two ends with hard plugs 4 after the mold is closed;

[0022] c. After injecting liquid into the tube blank, pressurize to make the tube blank fit the inner cavity of the mold;

[0023] d. Push the hard plugs at both ends inward to replenish the material, the material on one side of the boss enters the boss, and the material on the opposite side of the boss enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com