Integral direct-drive disc-type wheel hub motor

A direct-drive disc, in-wheel motor technology, used in motors, synchronous motors with static armatures and rotating magnets, electric vehicles, etc., can solve the problem of low space utilization, cooling system and motor rotor shaft strength. Consider and affect the service life of permanent magnets and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] Detailed ways: The present invention will be further described below in conjunction with accompanying drawing:

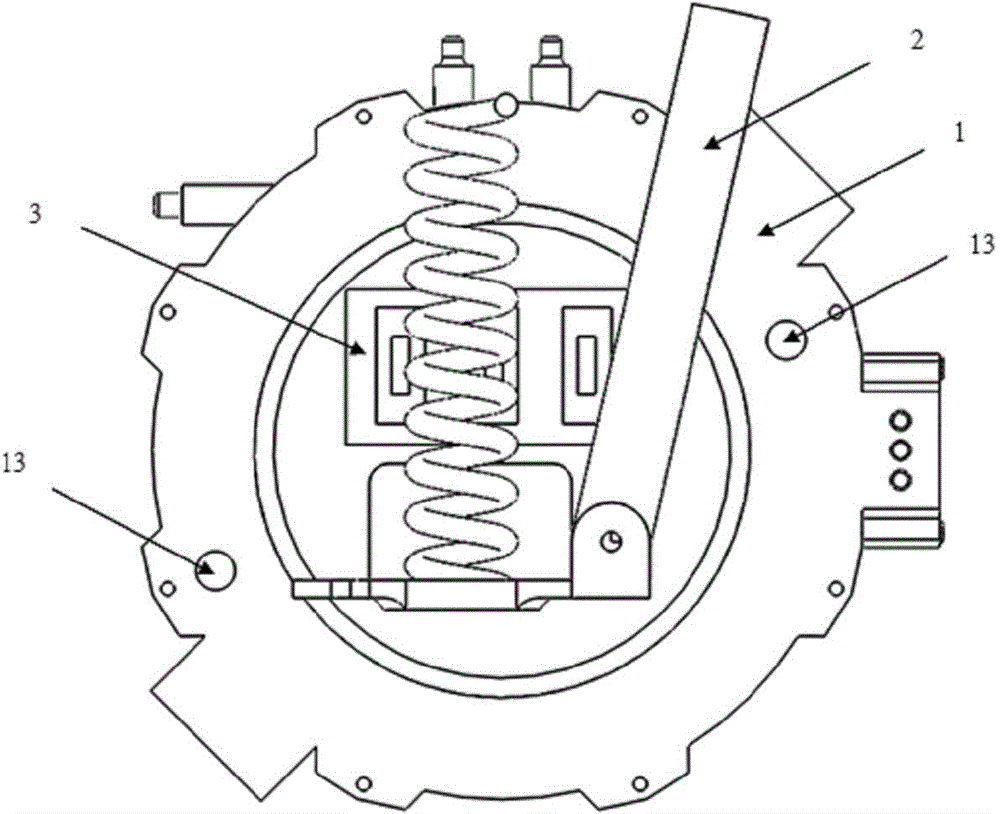

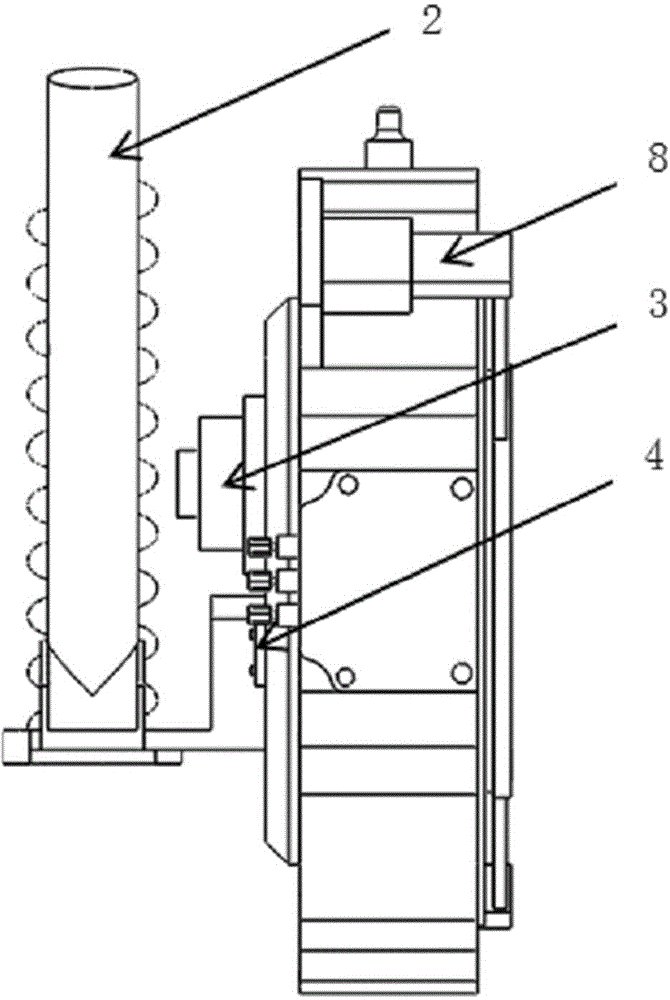

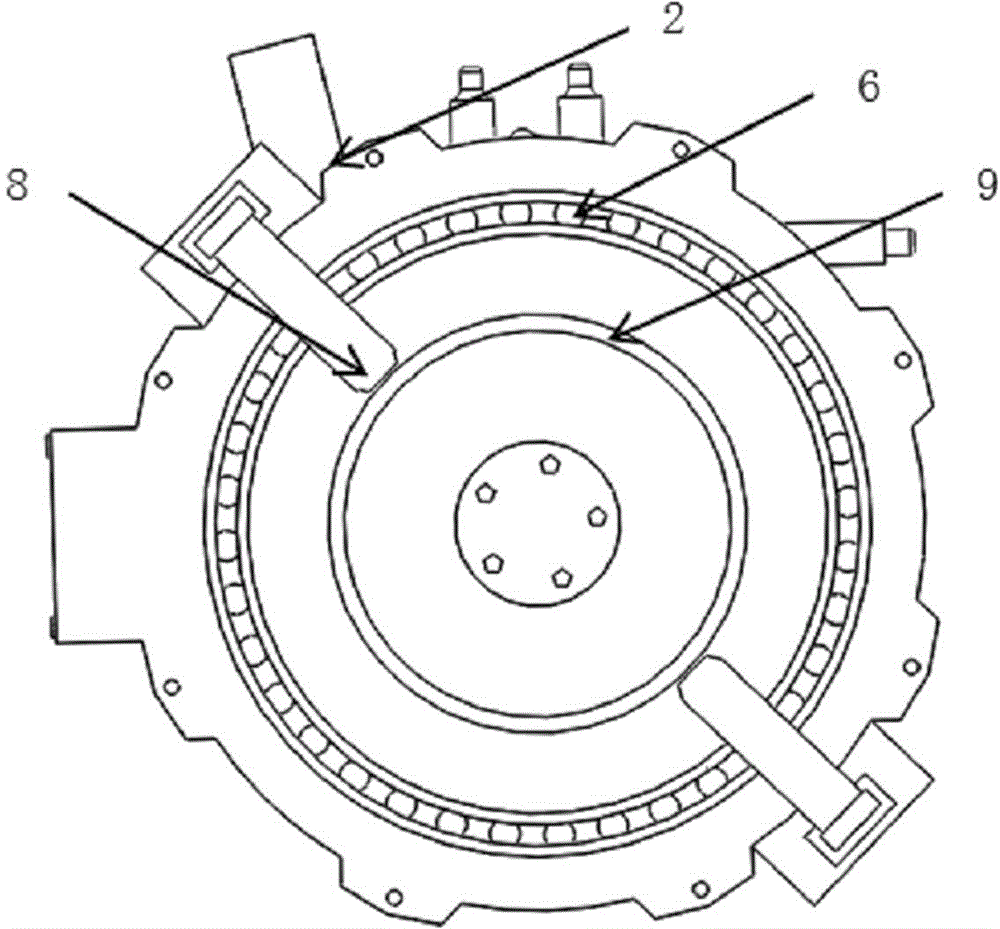

[0026] Such as figure 1 and 2 As shown, the present invention provides an integrated direct drive disc hub motor, the motor includes a motor stator 1 and a motor rotor 5, the motor stator 1 and the motor rotor cooperate to form the main structure of the motor; The hub rotates, and the stator part is connected with the suspension 2 of the automobile; the motor stator 1 and the motor rotor 5 are matched through the bearing 6, the motor stator 1 is provided with motor windings, and the motor rotor 5 is punched by stacking permanent magnets and fixed permanent magnets Composed of silicon steel sheets.

[0027] A magnetoelectric encoder 8 for detecting the position of the motor rotor is arranged on the motor stator 1, and the magnetoelectric encoder 8 is in contact with the magnetic encoder code disc 9 fixed on the motor rotor and rotating concentrically with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com