Milk maker

A milk frother and container technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of burning food, inconvenient cleaning, poor electrical safety performance, etc., and achieve a large contact area, easy cleaning, and heat transfer. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The milk frother of the present invention is suitable for frothing or heating various kinds of milk and milk powder.

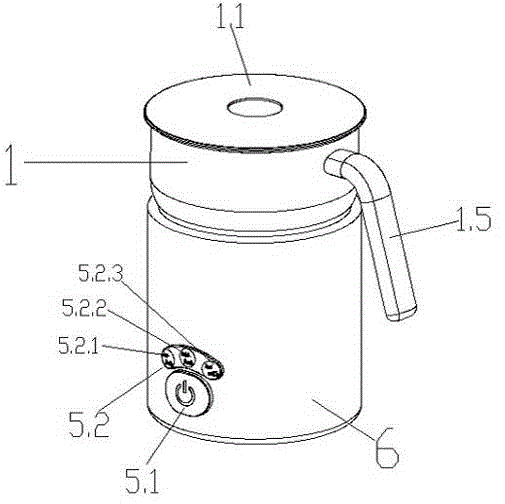

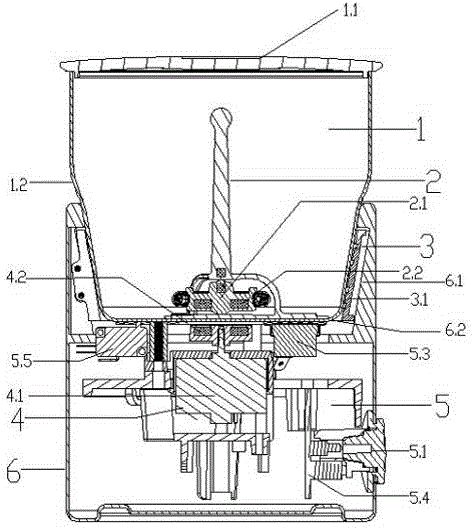

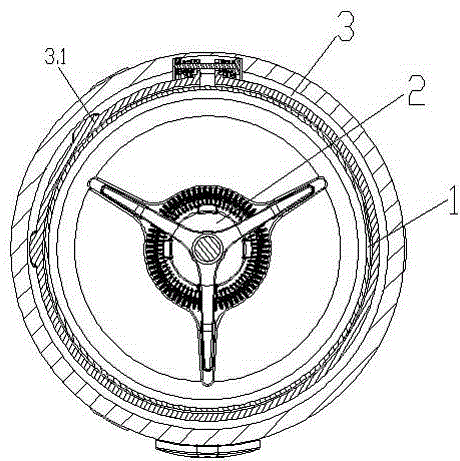

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 Preferred embodiments of the milk frother of the present invention will be described in detail below.

[0025] A milk frother in this embodiment includes a container 1, a base 6, a circuit control device 5, a stirring device 2 and a driving device 4, the stirring device 2 is located in the container 1, and it is characterized in that: It includes a ring-shaped heating device 3, which is installed on the base 6, the ring-shaped heating device 3 is obliquely tapered, the side wall of the lower part of the container 1 is obliquely tapered, and the container 1 The lower side wall fits movably with the annular heating device 3 , and the container 1 can be separated from the base 6 when not working.

[0026] In this embodiment, the oblique taper shape of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap