Dynamic correction mechanism for screw lock

A dynamic correction and screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced success rate of electric batch lock screws, defective products, and increased production costs, so as to improve work efficiency and reduce defective rates. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

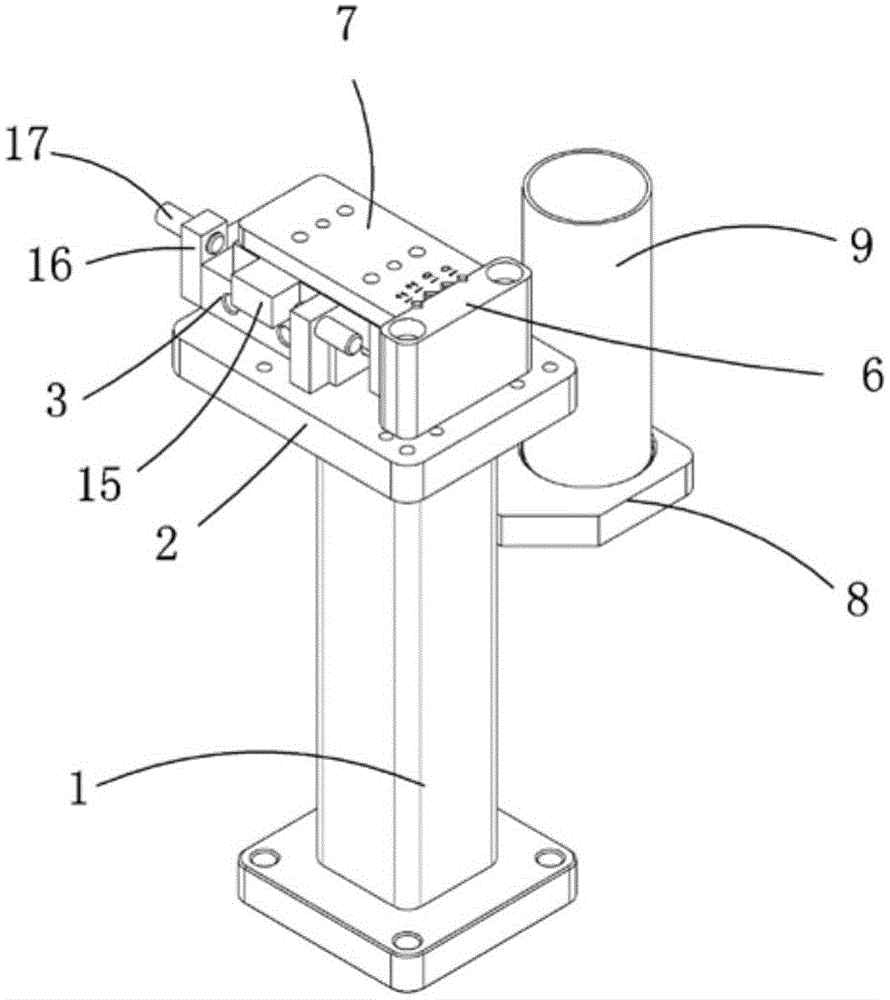

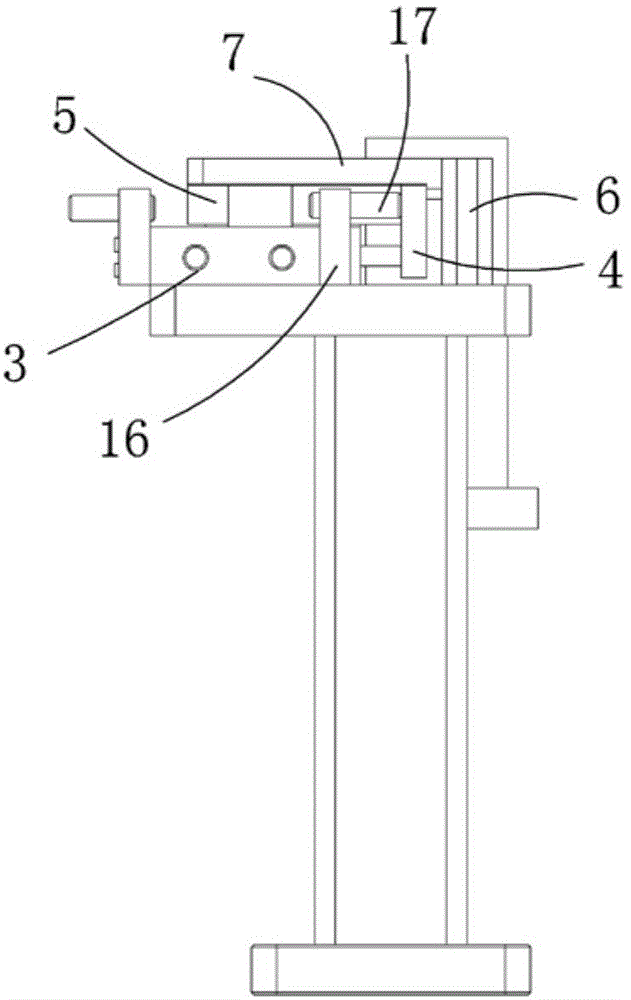

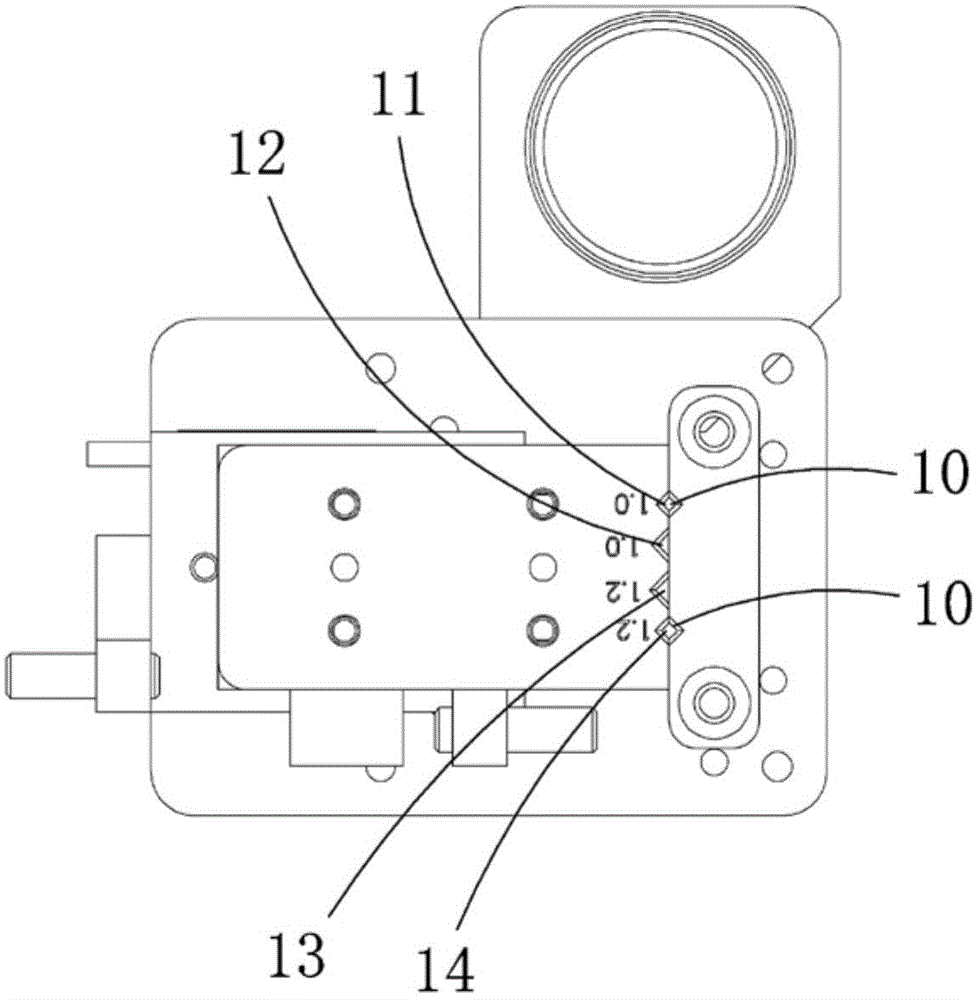

[0019] Examples, see attached Figure 1~4 , A screw-locking dynamic correction mechanism, which includes a corrector base 1, a cylinder fixing plate 2, a cylinder 3, a push plate 4, a moving plate 5, a correction block a6, a dynamic correction block 7, a magnet fixing plate 8 and a waste bucket 9 , The cylinder fixing plate is installed on the corrector base; the cylinder is installed on the upper left side of the cylinder fixing plate, the front end of the piston rod of the cylinder is connected to the push plate, and the push plate and the moving plate are fixedly connected together, and the moving plate is located Above the cylinder, the cylinder can drive the push plate to drive the moving plate to move; a magnet fixing plate is installed on the back of the corrector base. The magnet fixing plate is provided with a groove in which a magnet is placed, and the waste bucket is adsorbed on the magnet. Its adsorption and fixation is stable and reliable, and it is easy to replace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com