A deep hole screw locking machine and its application method

A screw locking machine, screw machine technology, applied in metal processing equipment, metal processing, manufacturing tools and other directions, can solve the problem that the screw cannot be accurately fed into the screw hole, the screw is easy to tilt, and the deep hole screw cannot be locked and paid. , to achieve the effect of convenient locking, precise positioning and preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

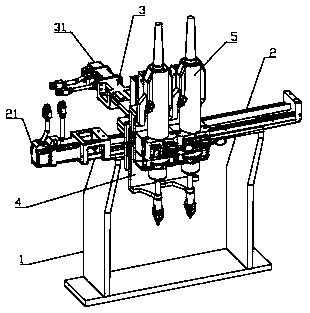

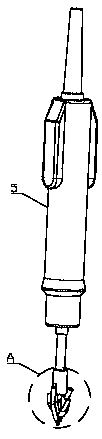

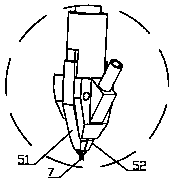

[0047] Such as figure 1 As shown, a kind of deep hole screw lock payer of the present invention comprises frame 1, is installed on frame 1 and is used for driving the lateral movement mechanism 2 of screw machine 5 to move left and right, and one end of lateral movement mechanism 2 is installed for driving lateral movement mechanism 2. The horizontal drive motor 21 of the moving mechanism 2 works; the vertical moving mechanism 3 for driving the screw machine 5 to move back and forth is installed on the horizontal moving mechanism 2, and the longitudinal driving motor for driving the vertical moving mechanism 3 is installed on the rear end of the vertical moving mechanism 3 31; the front end of the longitudinal movement mechanism 3 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com