An equivalent substitute material for frost heave cracking of fractured rock and its preparation method

A technology of rock and frost heaving, applied in the field of effective alternative materials, can solve the problems of accelerated deterioration of rocks containing cracks, long cycle times, and inconspicuous effects, and achieve reliable results, good accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An equivalent substitute material for frost heaving and cracking of fractured rocks, the substitute material includes the following raw materials in parts by weight

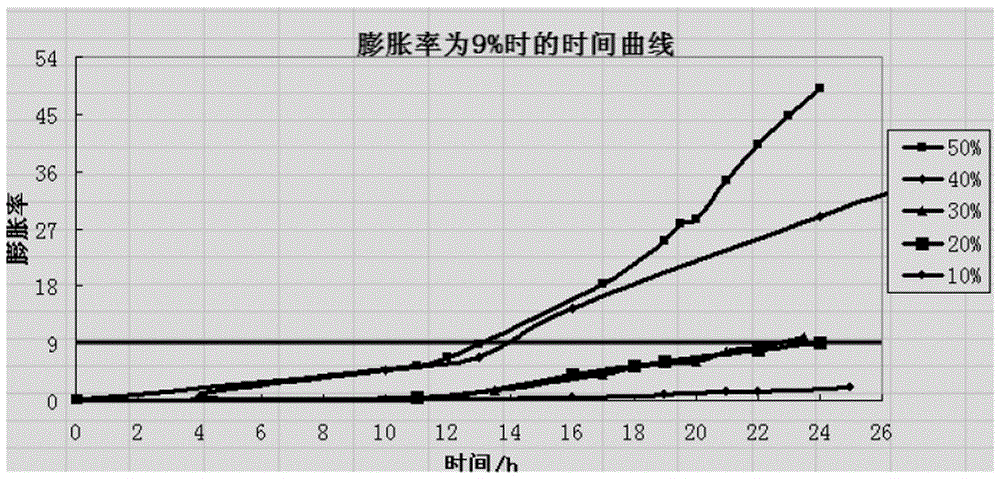

[0036] Composition: 10 or 20 or 30 or 40 or 50 parts of CaO, 50 parts of a mixture of Portland cement and high alumina cement with a strength greater than 32.5, 22 parts of gypsum, 5.85 parts of benzenesulfonic acid and 1.25 parts of hydrogen peroxide, 8 parts lignosulfonate. Put the above materials into the reactor in turn, add water and stir at a temperature of 25°C to prepare a slurry, continue to stir the slurry until the slurry solidifies, and control the expansion rate of the solidified substance to 9%, and the elasticity of the solidified substance is 500MPa, That is, it is an equivalent substitute material for frost heaving and cracking of fractured rocks.

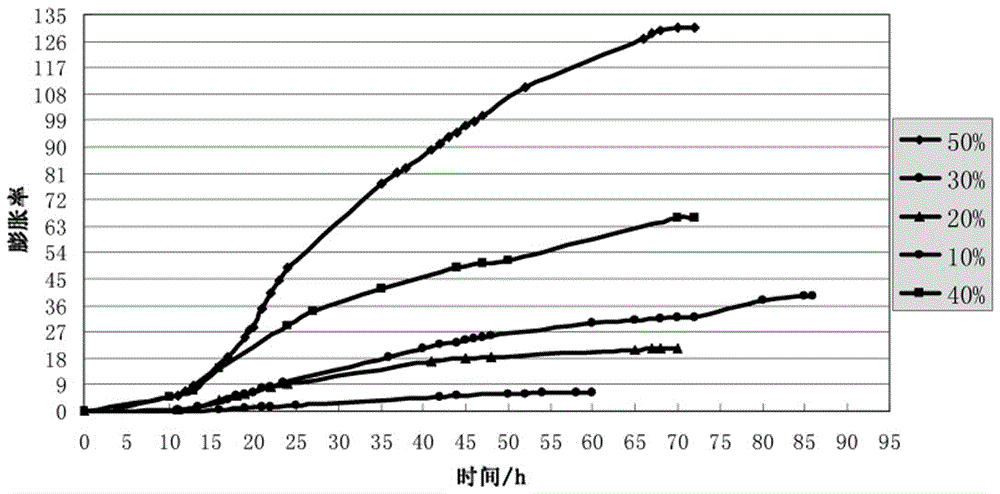

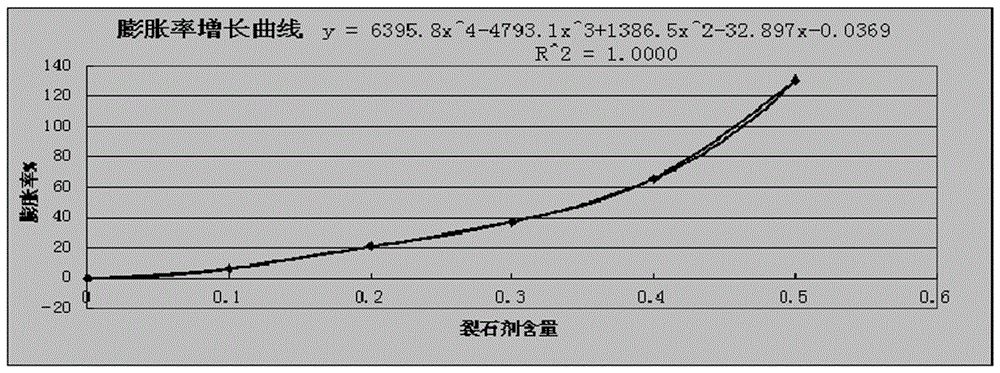

[0037] figure 1 It is the growth curve of expansion rate with time for different calcium oxide contents. From the figure, it can be seen th...

Embodiment 2

[0056] An equivalent substitute material for frost heaving and cracking of fractured rocks, the substitute material includes the following raw materials in parts by weight

[0057] Composition: 15 parts of Ti-CaO, 48 parts of a mixture of Portland cement and high alumina cement with a strength greater than 32.5, 12.5 parts of gypsum, 10.5 parts of oxalic acid, 0.9 parts of hydrogen peroxide, and 4.5 parts of polyvinyl alcohol. Put the above materials into the reactor in turn, add water and stir at a temperature of 25°C to prepare a slurry, continue to stir the slurry until the slurry solidifies, and control the expansion rate of the solidified substance to 9%, and the elasticity of the solidified substance is 500MPa, That is, it is an equivalent substitute material for frost heaving and cracking of fractured rocks.

Embodiment 3

[0059] An equivalent substitute material for frost heaving and cracking of fractured rocks, the substitute material includes the following raw materials in parts by weight

[0060] Composition: 18 parts of Ti-CaO, 42 parts of high alumina cement mixture, 18 parts of gypsum, 2.8 parts of citric acid, 1.25 parts of sodium peroxide, and 4.5 parts of polyvinyl alcohol. Put the above materials into the reactor in turn, add water and stir at a temperature of 25°C to prepare a slurry, continue to stir the slurry until the slurry solidifies, and control the expansion rate of the solidified substance to 9%, and the elasticity of the solidified substance is 500MPa, That is, it is an equivalent substitute material for frost heaving and cracking of fractured rocks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com