Cloth cleaning device and cleaning method

A technology of cleaning device and cloth feeding device, which is applied in the processing of textile materials, inspection of textile materials, spraying/spraying of textile materials, etc. It can solve problems such as low efficiency, occupational injury, and no waste water and waste gas collection device, and achieve operational efficiency. The effect of natural movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

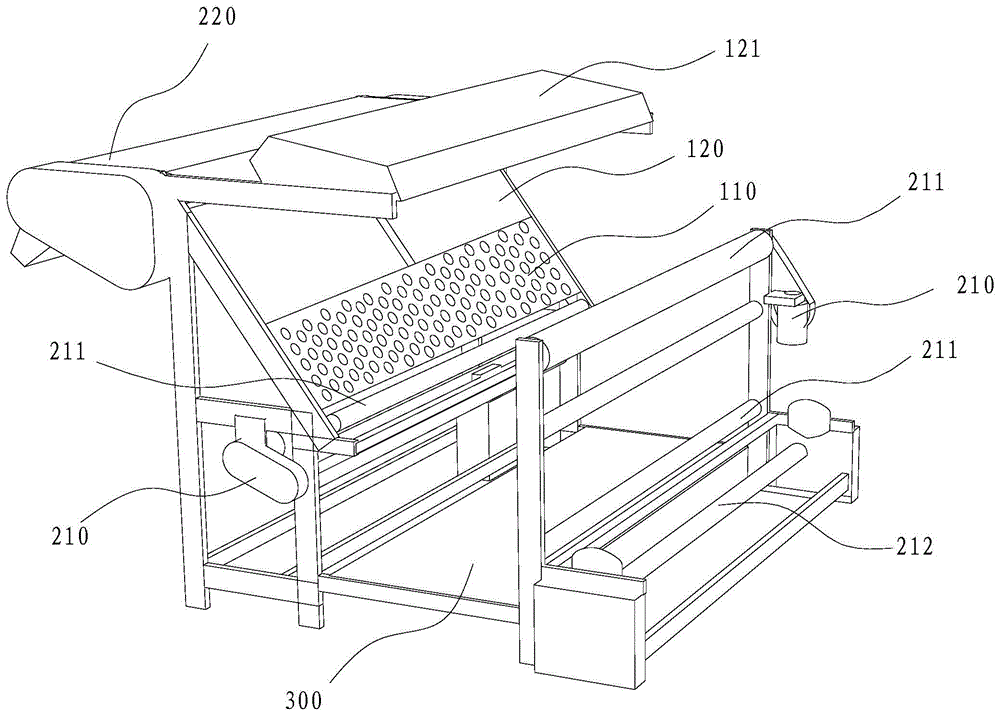

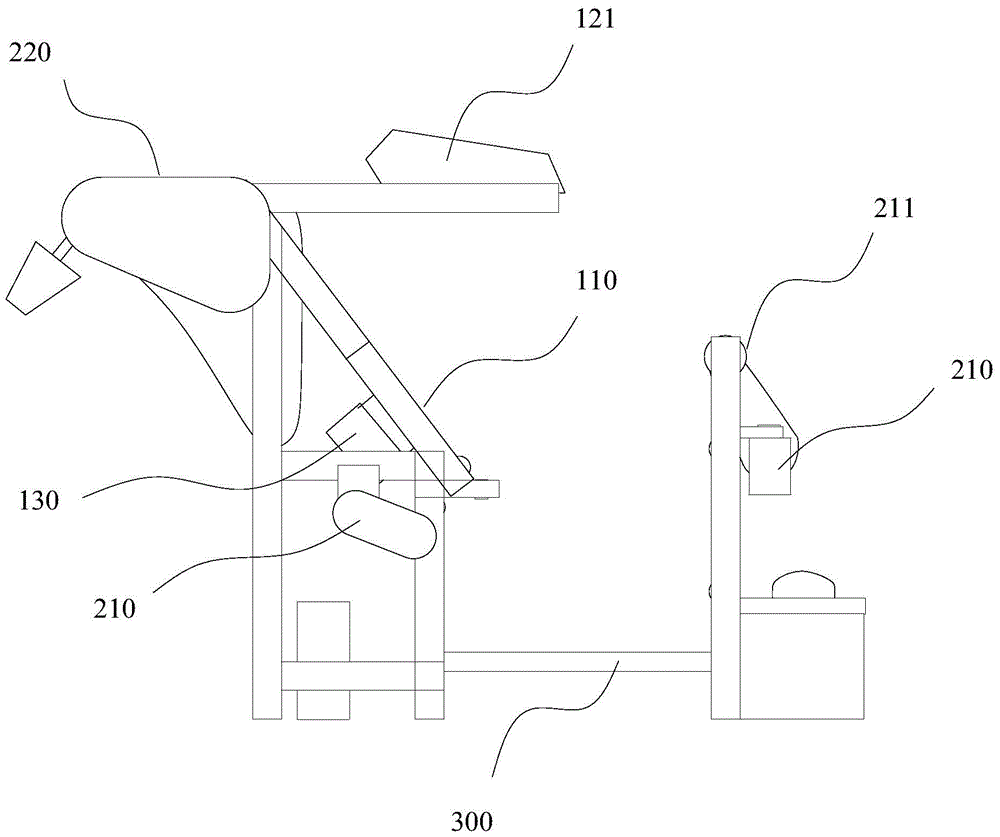

[0034] like Figures 1 to 6 As shown, the cloth cleaning device includes a working table, a cloth feeding device, a suction device, and a cleaning spray gun, and the cleaning spray gun sprays a volatile cleaning agent.

[0035] The workbench includes a cleaning panel 110 and an inspection panel 120 .

[0036] There is a cover 130 matched with the back of the cleaning panel 110, and the cleaning panel 110 and the cover 130 enclose a negative pressure chamber. The cleaning panel 110 is distributed with a plurality of sewage suction holes 111, and the casing 130 has a sewage outlet 131, which is connected with a suction device, which can be an exhaust fan or an existing negative pressure device.

[0037] There is an inspection lamp 121 above the inspection panel 120 , and the light of the inspection lamp 121 directly shines on the inspection panel 120 .

[0038] The cleaning panel 110 and the inspection panel 120 are connected side by side, the cleaning panel 110 and the inspec...

Embodiment 2

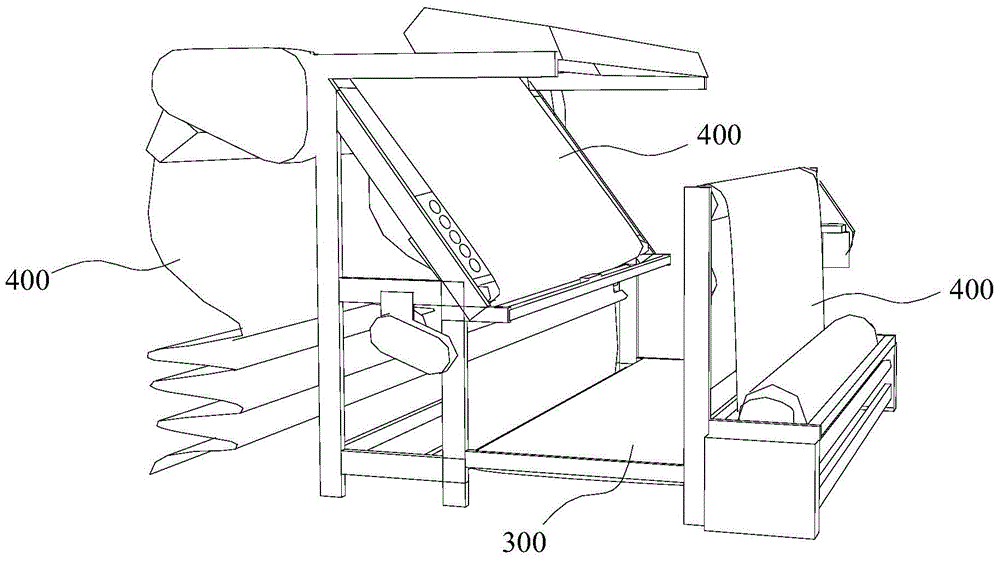

[0048] like Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the cloth to be cleaned is placed behind the platform in a folded manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com