Electric-control hydraulic adjustment mechanism based on camshaft and allowing valve lift to be changed continuously

A valve lift and electronically controlled hydraulic technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large flow inertia, small flow inertia, and fixedness, etc., to overcome complex structure and few mechanism parts , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

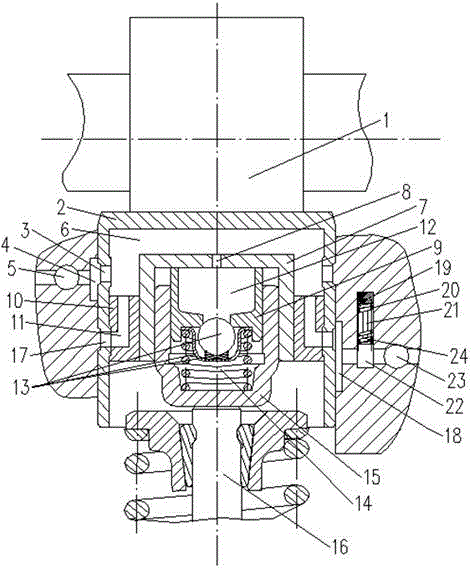

[0016] A continuously variable valve lift hydraulic adjustment mechanism, including a tappet body (2), a cam (1) linked to the tappet body, an oil inlet groove (4) connecting the main oil passage of the engine with an oil inlet hole, and an oil adjustment chamber (6), the sliding sleeve (7), the oil hole (8), the plunger connected with the valve (9), the oil drain channel (11), the one-way valve (13), the connection The oil return channel (23) of the engine, the oil return groove (18) of the oil return hole (17), and the control valve body (24), in which the sliding sleeve (7) is connected with the plunger sleeve (15) and the plunger (9) to form a The auxiliary oil chamber (12) and the high-pressure oil chamber (14), and the check valve (13) is located inside the high-pressure oil chamber to isolate the auxiliary oil chamber (12) and the high-pressure oil chamber (14).

[0017] The tappet (2) is in contact with the outer edge of the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com