Insulation pipe connector

A technology for pipe joints and thermal insulation, which is applied in thermal insulation, pipe/pipe joints/pipe fittings, and protection of pipelines through thermal insulation, etc. It can solve the problems of fast heat transfer and heat dissipation, large amount of engineering, affecting the appearance of pipelines, etc., so as to reduce heat The effect of transferring and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

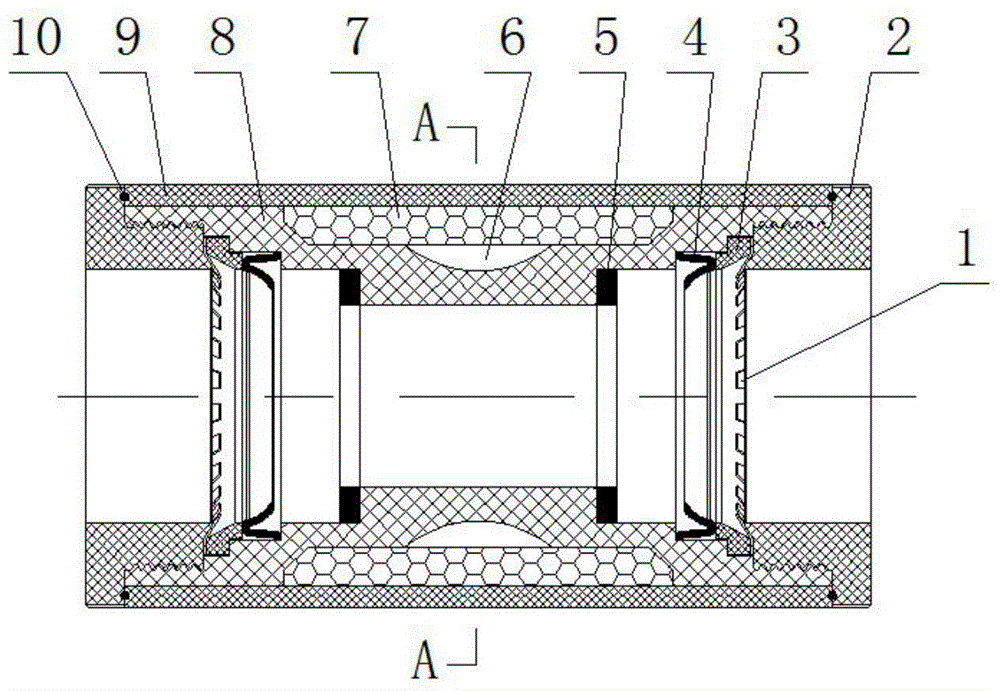

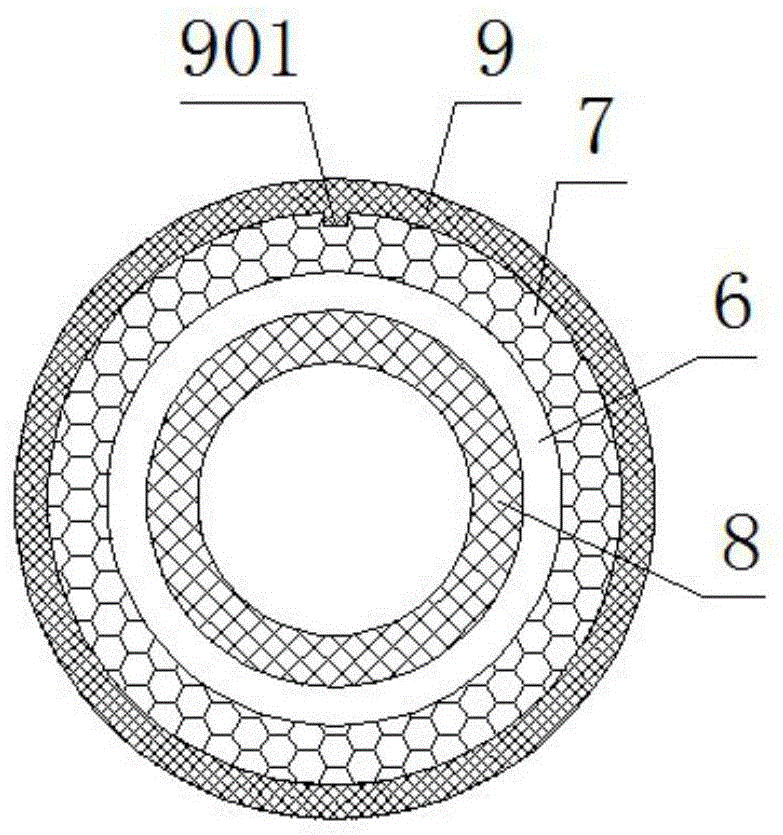

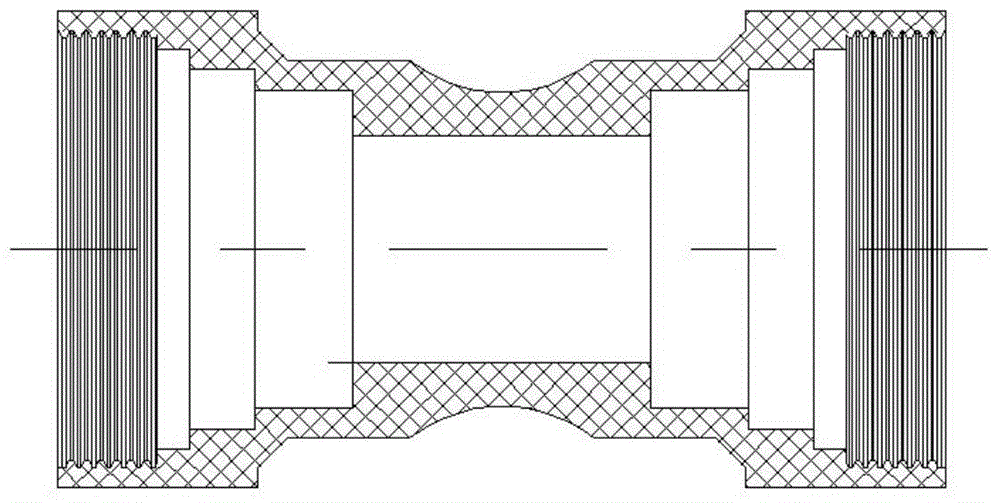

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a pipe joint for heat preservation according to the present invention includes a spring washer 1, an end cap 2, a pipe sleeve 3, a sealing ring A4, a sealing ring B5 and an inner pipe body 8, and the end cap 2 and the inner pipe body 8 is movably connected, and the sealing ring A4, the sleeve 3 and the spring washer 1 are sequentially installed between the inner tube body 8 and the end cover 2. Tightly fixed, the sealing ring A4 is a bowl-shaped rubber sealing ring, and the spring washer 1 is made of stainless steel; the inner pipe body 8 is provided with an insulating layer 7, and the material of the insulating layer 7 is polyurethane foam. A cavity 6 is formed between the layer 7 and the inner tube body 8, and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com