Patents

Literature

92results about How to "Avoid affecting the insulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

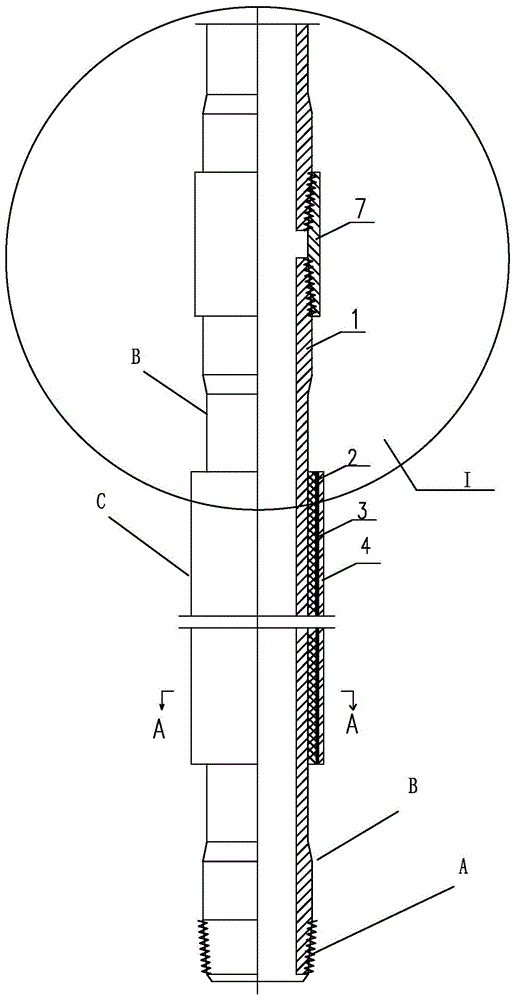

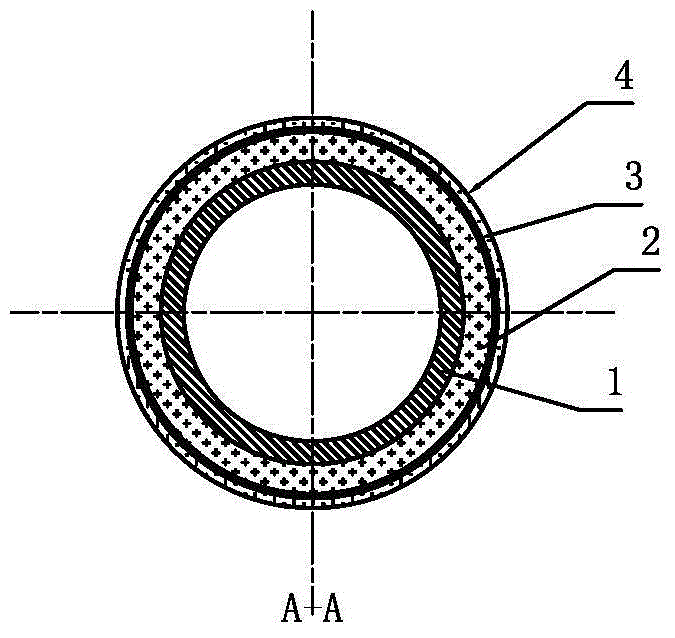

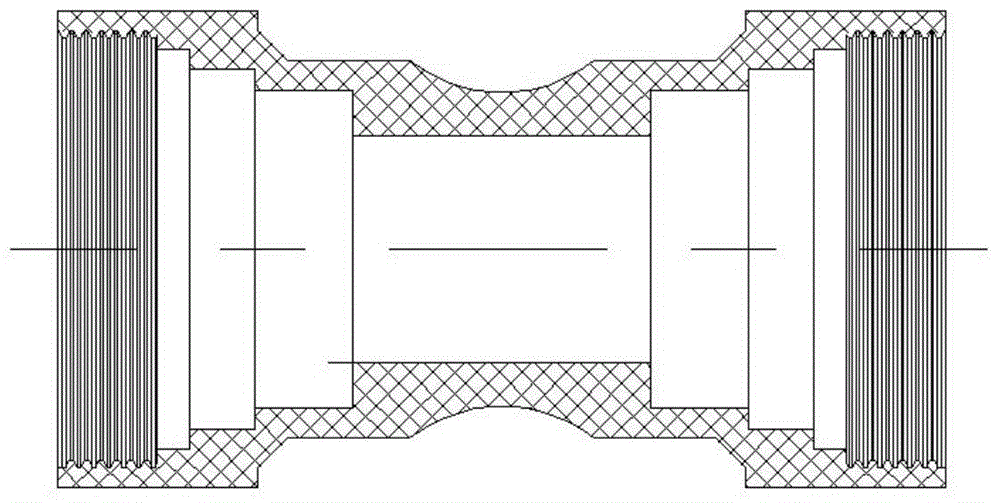

Sealing and heat insulating device for wrapped insulated tubing and manufacturing method thereof

InactiveCN104989289AImprove insulation effectSimple sealing structureDrilling rodsDrilling casingsHoopingInsulation layer

The invention relates to a sealing and heat insulating device for a wrapped insulated tubing and a manufacturing method thereof. Sealing hoops are installed at the two ends of an anti-corrosion protecting layer located on the middle section of the tubing, in other words, the tubing is sleeved with buna-N silicon seals. The anti-corrosion protecting layer is arranged outside the buna-N silicon seals in an extending and wrapping mode, and stainless steel rings are arranged to achieve binding and forceful sealing between the anti-corrosion protecting layer and the buna-N silicon seals and the tubing. Multiple stainless steel hooping pipe clamps are arranged on the upper portion, the middle portion and the lower portion of the outer wall of a semicircular insulated protecting pipe sleeve, and a longitudinal sealing bar is arranged at the position of a butt joint of the semicircular insulated protecting pipe sleeve. The semicircular insulated protecting pipe sleeve is of a structure that buna-N materials are arranged on the periphery and aerogel insulation felt is clamped in the middle. No oil-gas-water substance can enter the space between the insulation layer and the tubing and the space between the insulation layer and the protecting layer, so that the heat insulation effect of the whole wrapped insulated tubing is better and oil exploitation cost is reduced greatly.

Owner:刘兴仁 +1

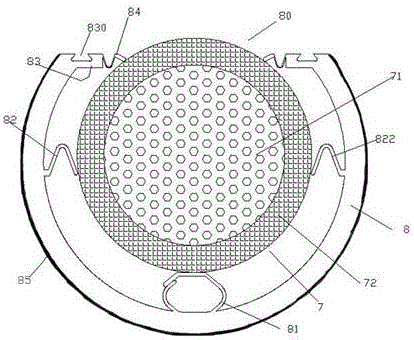

Anti-corrosion cable equipped with thermal-insulating protection cover and assembling and mounting method for anti-corrosion cable

InactiveCN105895219ANot easy to break awayAvoid squeezingInsulated cablesInsulated conductorsAnti-corrosionPetroleum engineering

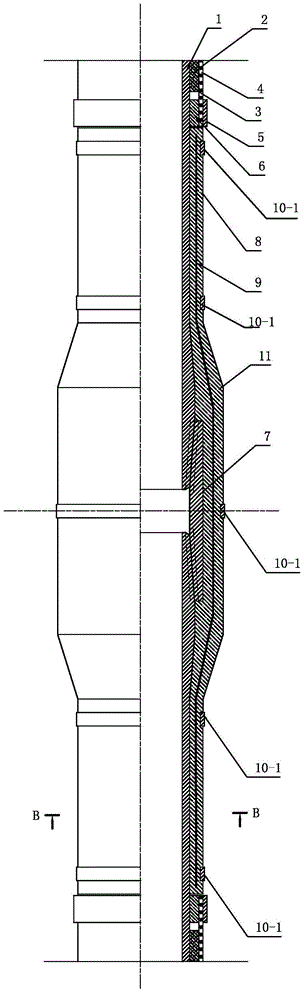

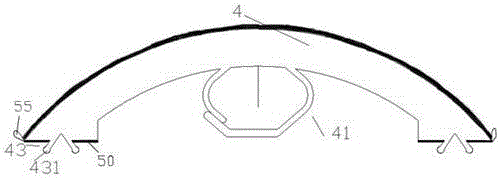

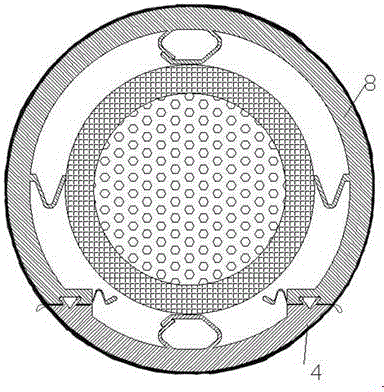

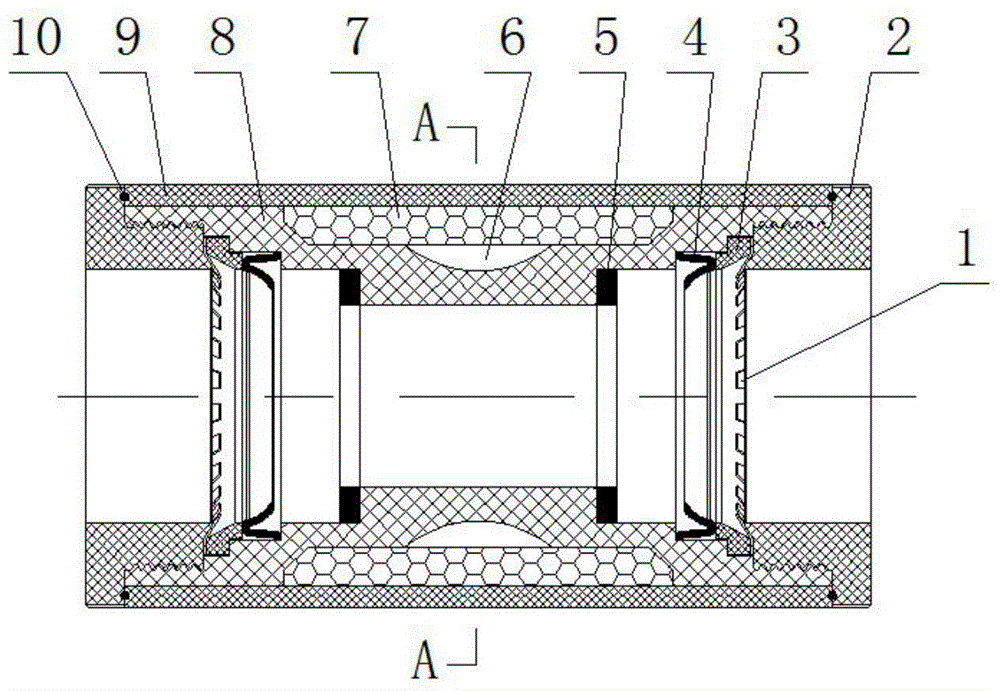

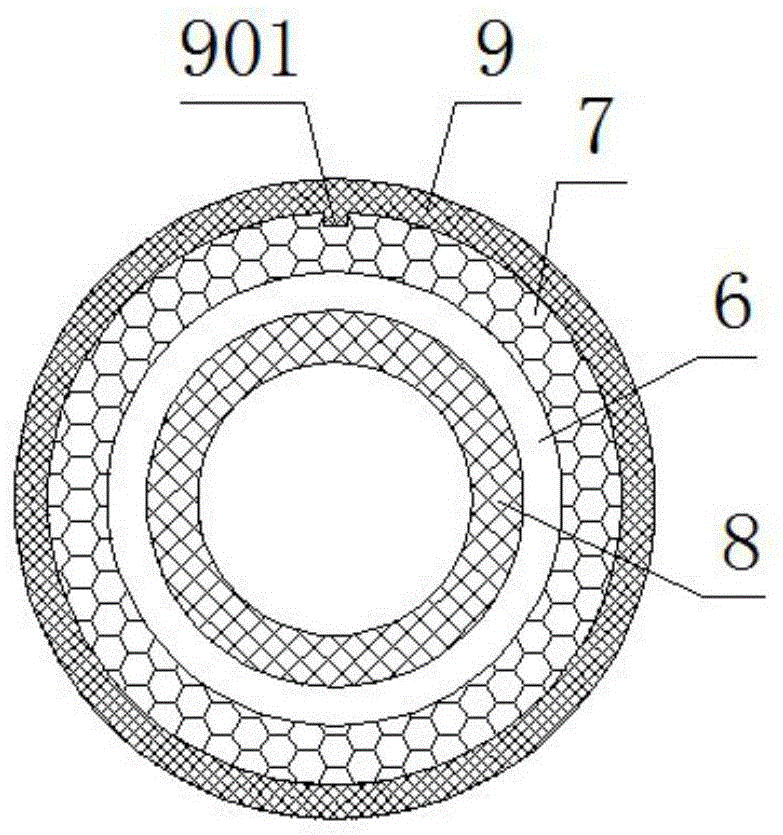

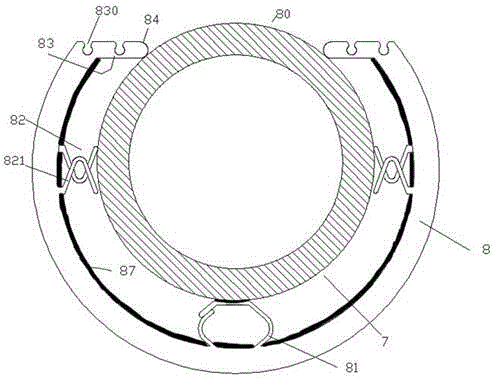

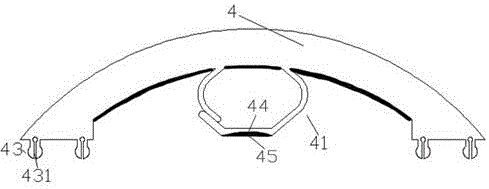

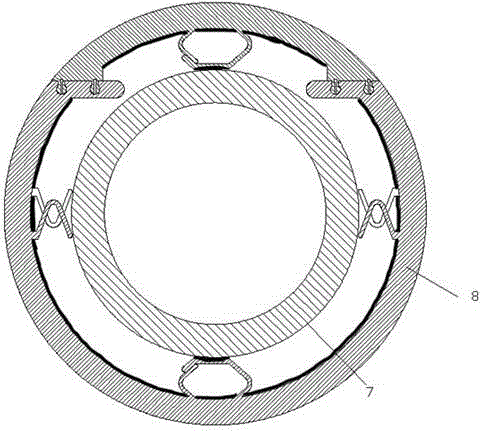

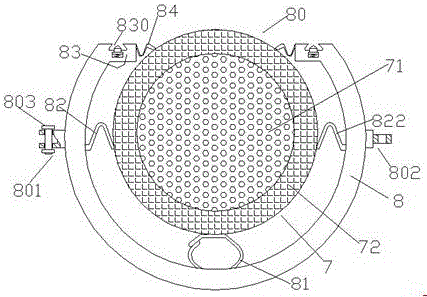

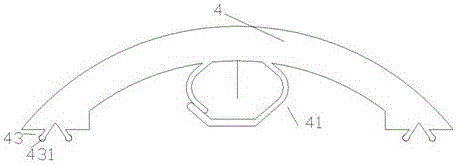

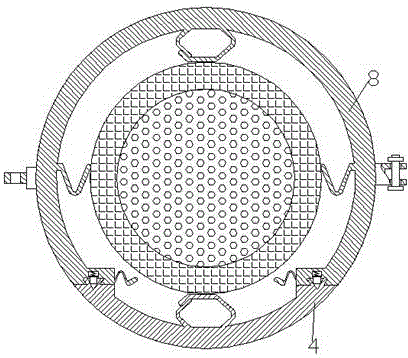

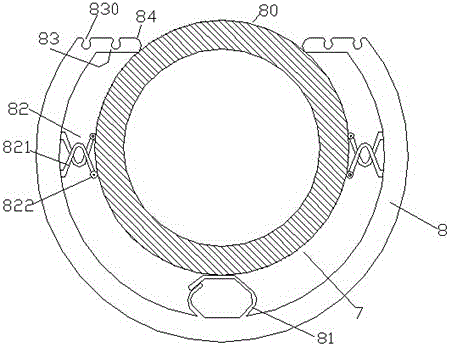

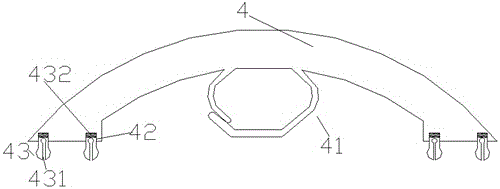

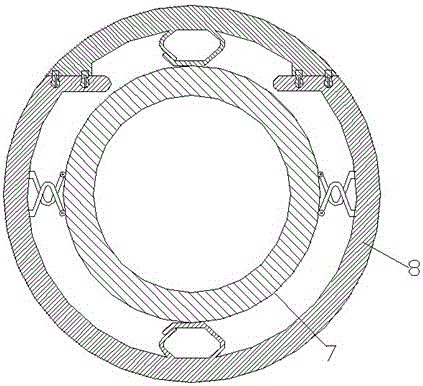

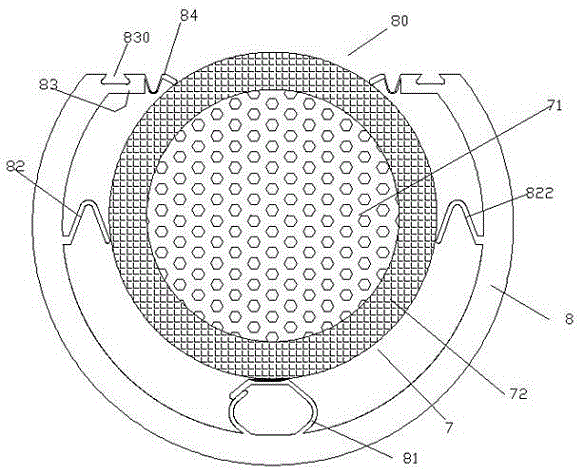

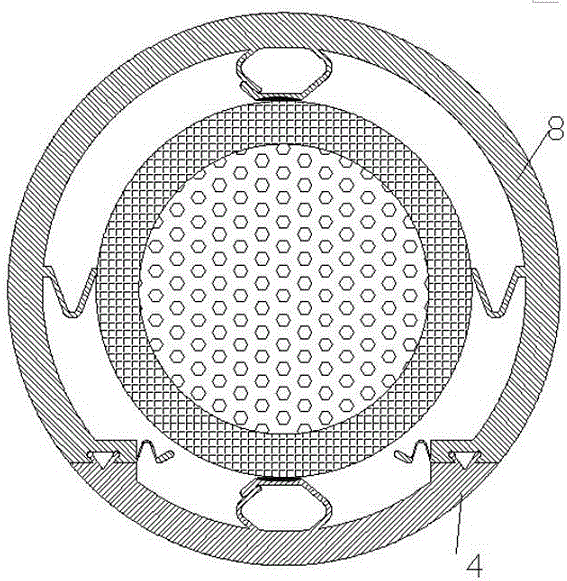

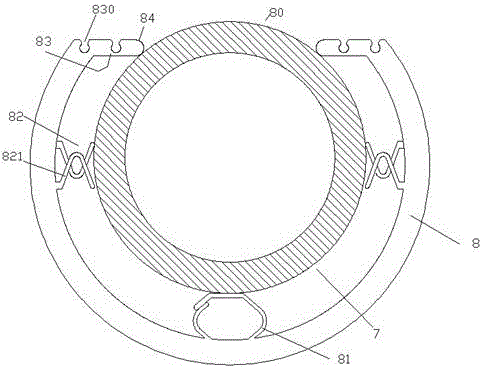

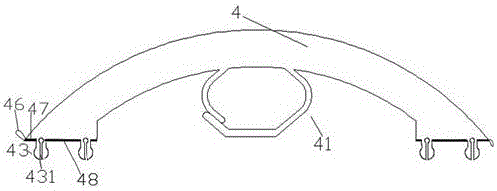

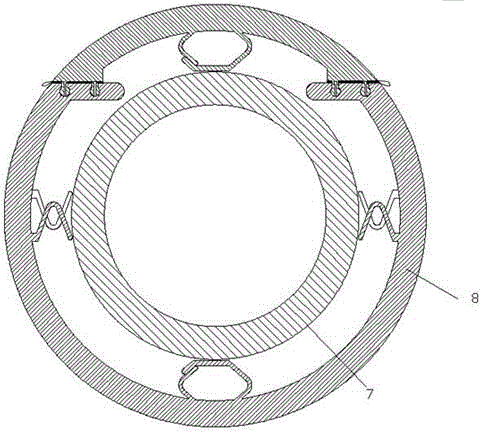

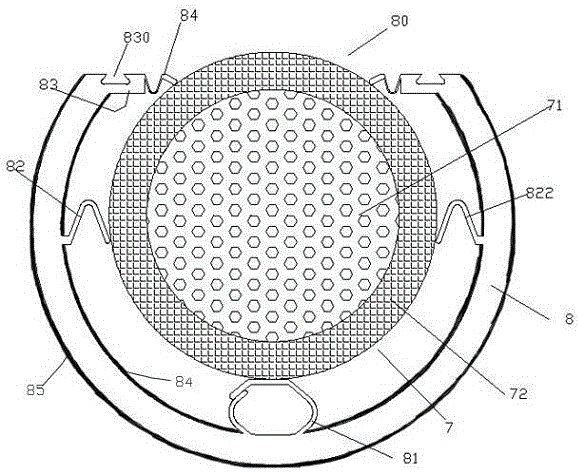

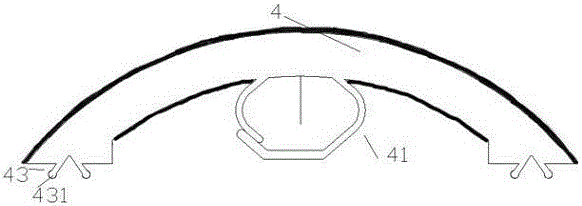

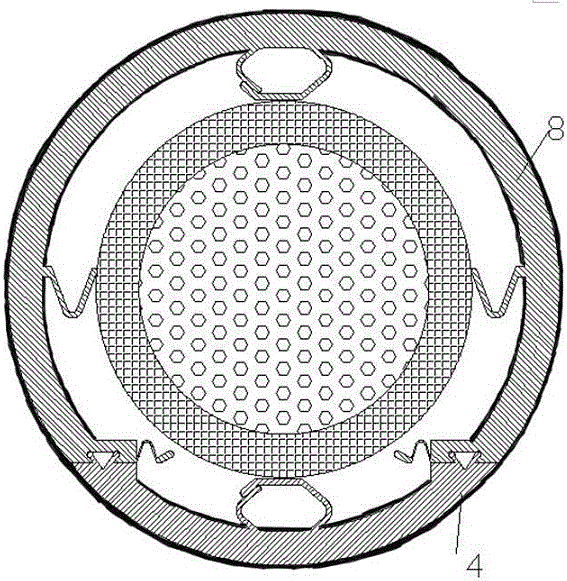

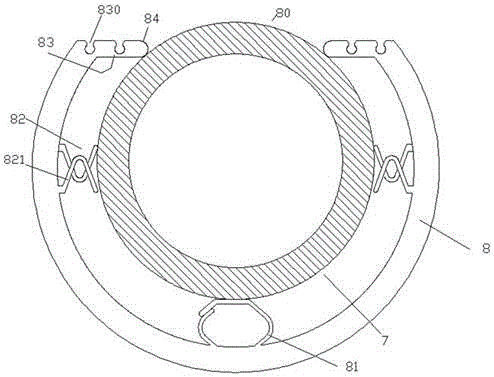

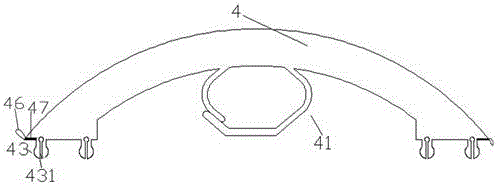

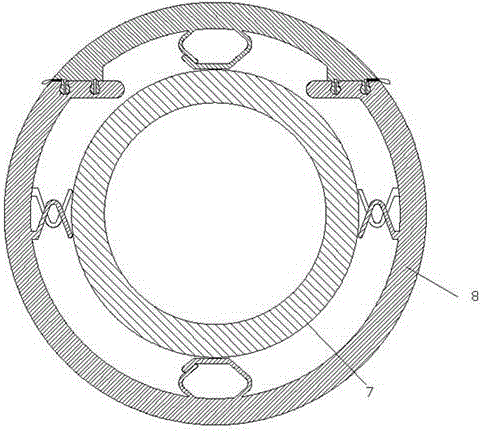

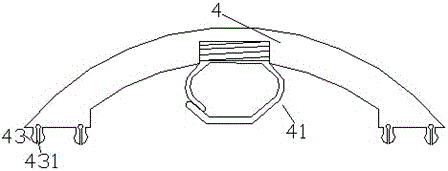

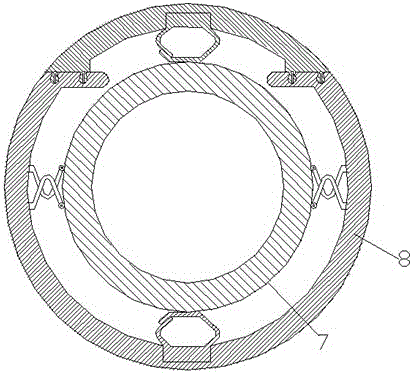

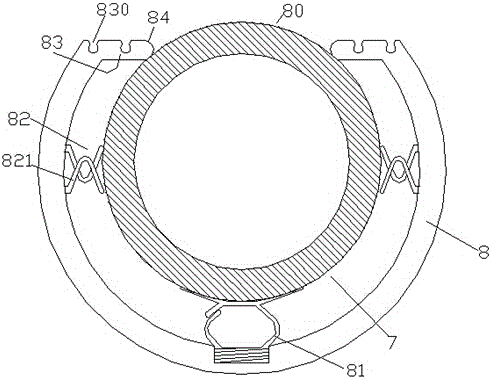

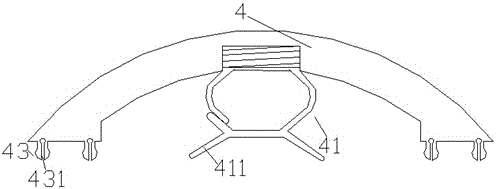

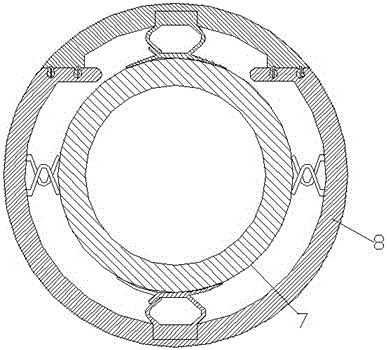

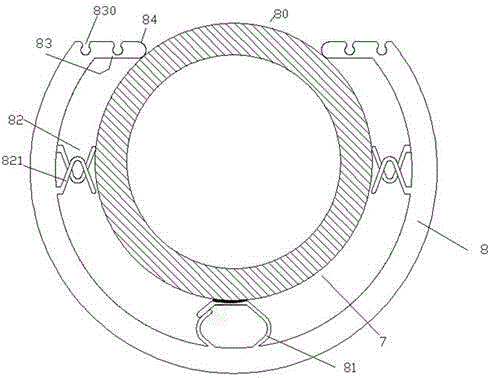

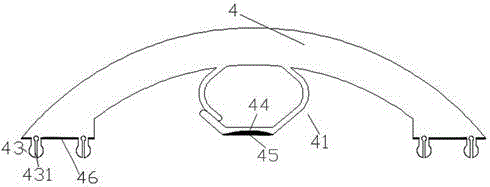

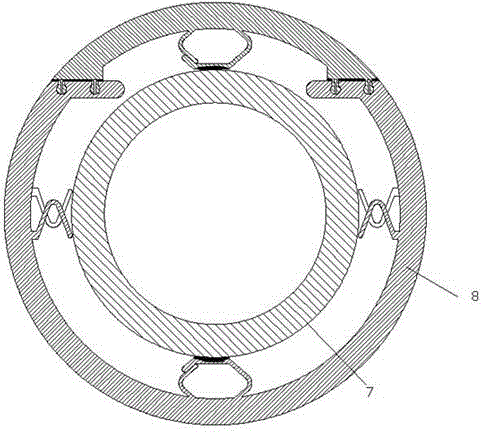

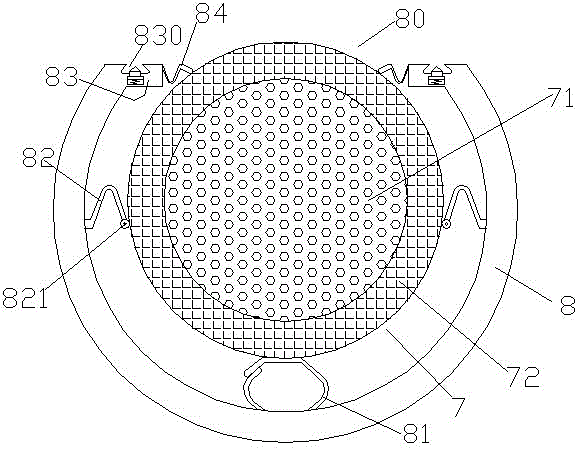

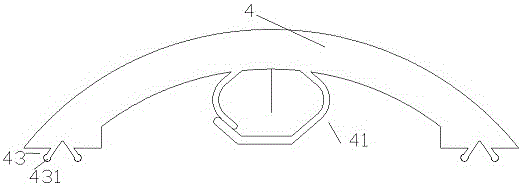

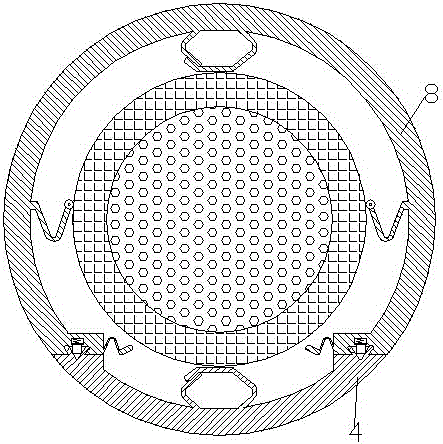

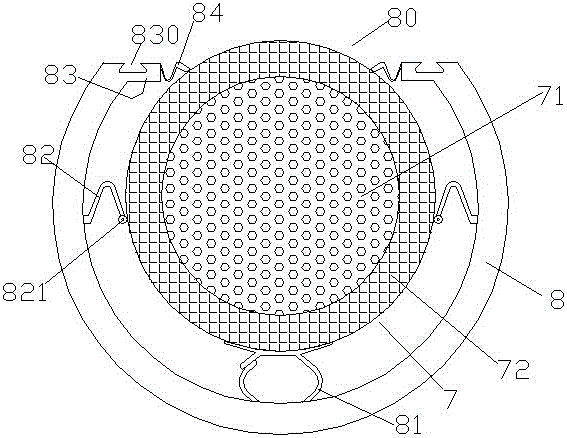

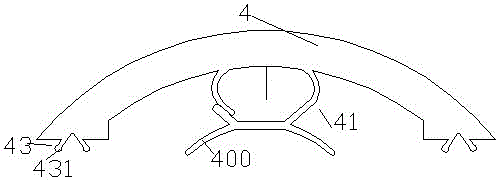

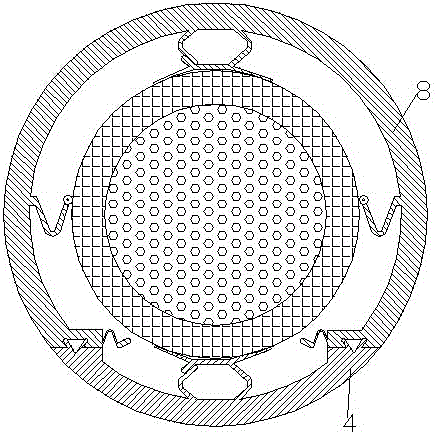

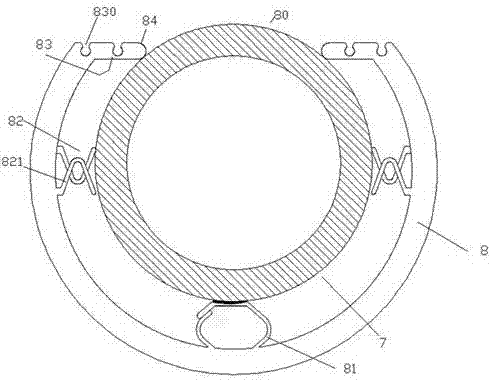

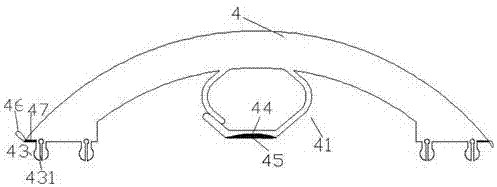

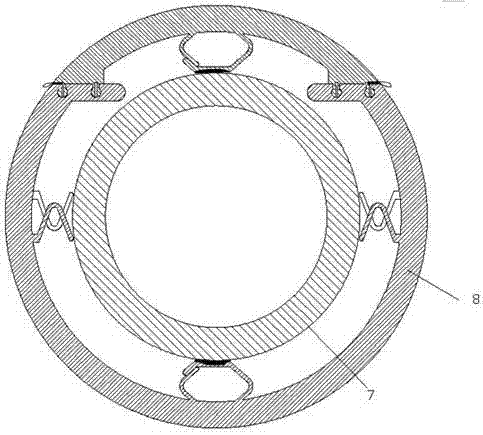

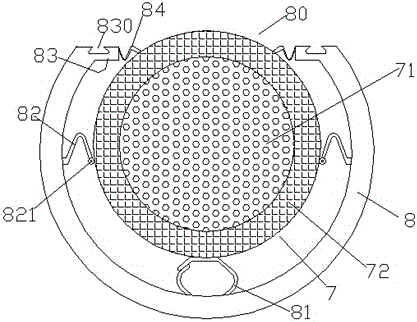

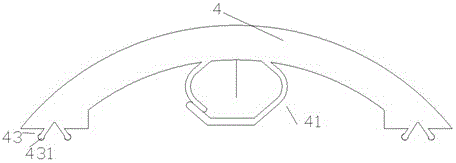

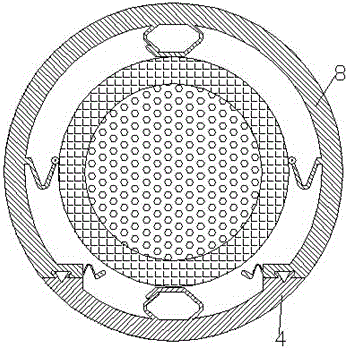

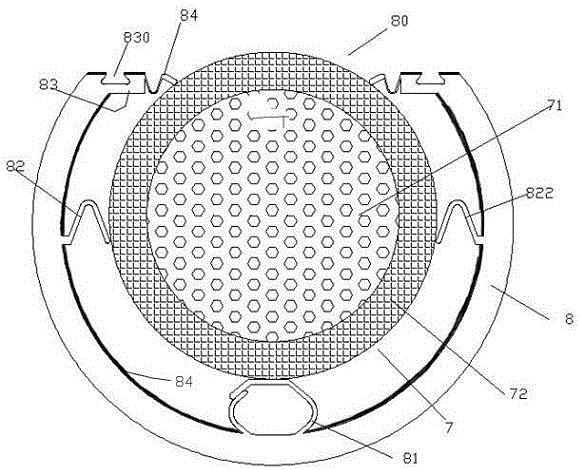

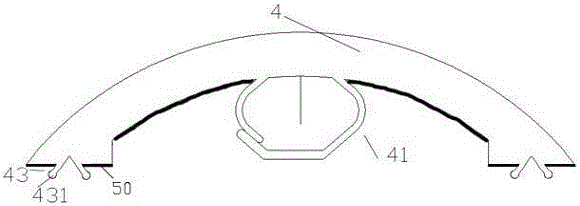

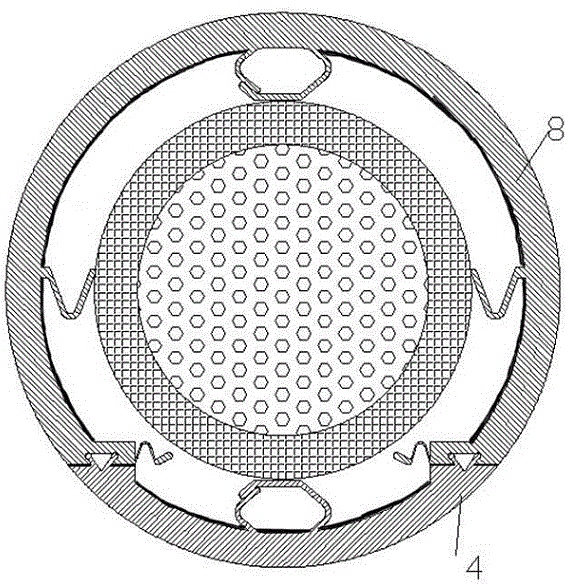

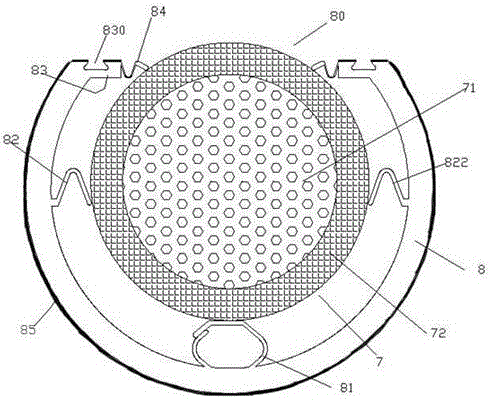

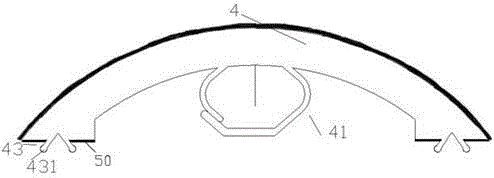

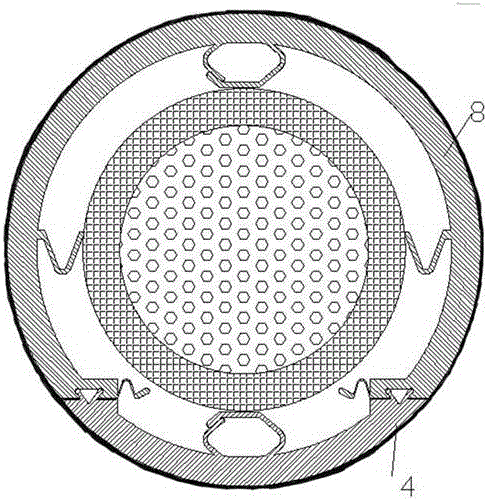

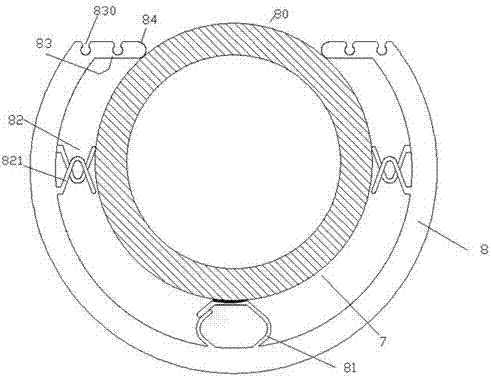

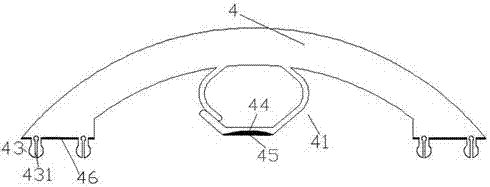

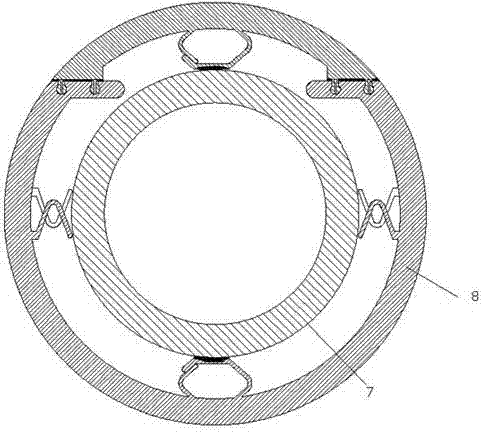

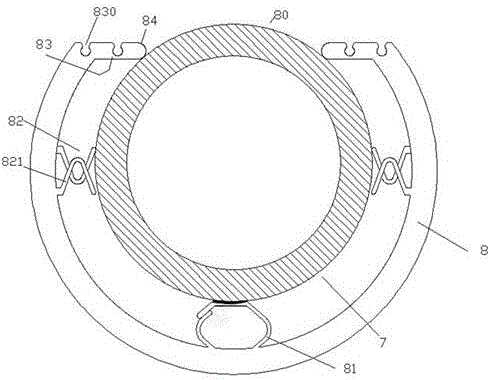

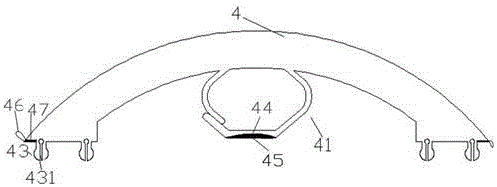

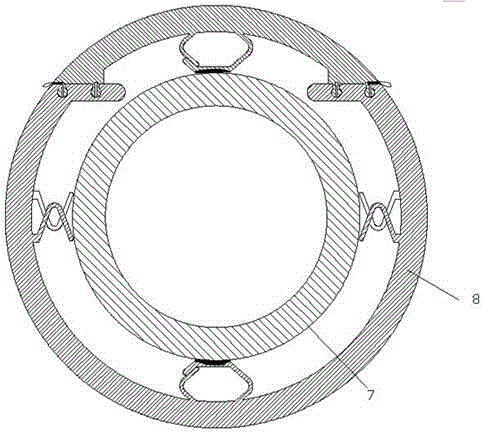

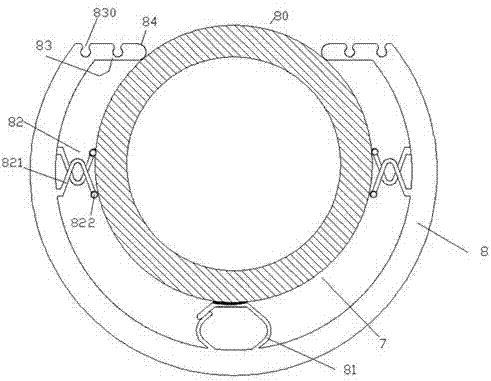

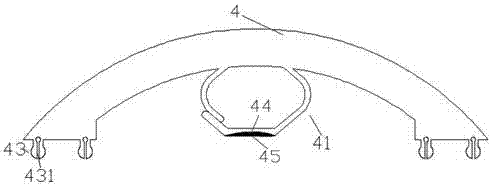

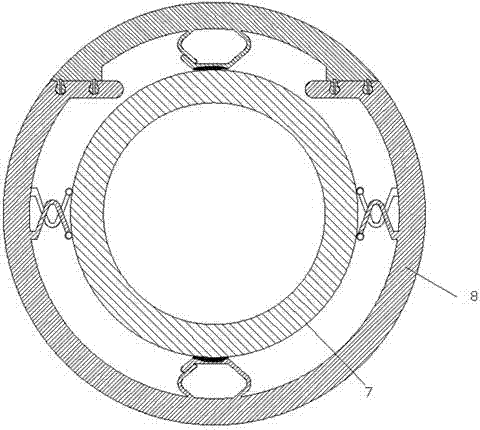

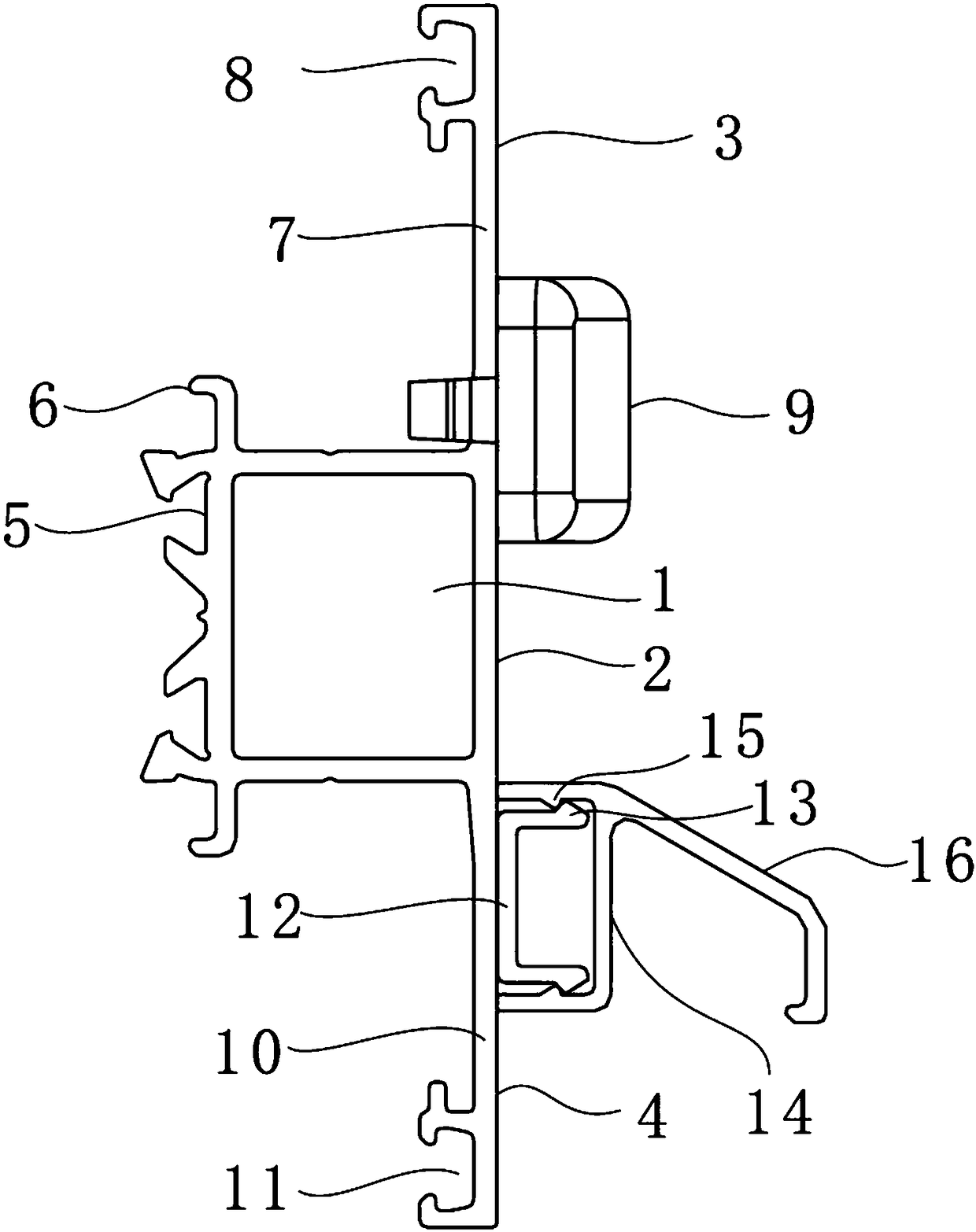

The invention discloses an anti-corrosion cable equipped with a thermal-insulating protection cover and an assembling and mounting method for the anti-corrosion cable. The cable comprises a cable core body (7) consisting of a cable core part (71) and an insulating wrapping layer (72), and the thermal-insulating protection cover, wherein the thermal-insulating protection cover comprises a main accommodating part (8) used as a relatively big circular-nick part section cylinder and a cover body part (4) used as a relatively small circular-nick part section cylinder, and the main accommodating part (8) and the cover body part (4) can be combined into a cylinder body, wherein elastic opposite-vertex platform pipes (81, 41) are symmetrically arranged at the bottom of the main accommodating part (8) and the top of the cover body part (4); and elastic clamping parts (82) are symmetrically arranged at the opposite positions in the diameter direction of the main accommodating part (8).

Owner:曲旭贵

Insulation pipe connector

InactiveCN104455941APrevent slipping and cannot be disassembledReduce lossesThermal insulationPipe protection by thermal insulationInsulation layerHeat losses

The invention discloses an insulation pipe connector and belongs to the technical field of water heating pipeline connection. The insulation pipe connector comprises an elastic cushion, an end cover, a pipe sleeve, a sealing ring A, a sealing ring B and an inner pipe body. The end cover is movably connected with the end cover, the sealing ring A, the pipe sleeve and the elastic cushion are sequentially installed between the inner pipe body and the end cover, the sealing ring B is located on a step end face in the inner pipe body, an insulation layer is arranged outside the inner pipe body and is made of polyurethane foaming plastic, a cavity is defined between the insulation layer and the inner pipe body, and an outer pipe body is further arranged outside the inner pipe body. According to the technical scheme, the insulation layer is arranged between the inner pipe body and the outer pipe body, meanwhile, the cavity is reserved between the inner pipe body and the insulation layer through the structural design of the inner pipe body, the double-insulation effect is achieved through insulation in a material isolation type and the insulation principle of an air convection prevention type, heat transfer is reduced to the maximum, and the heat loss at the pipe connector is reduced.

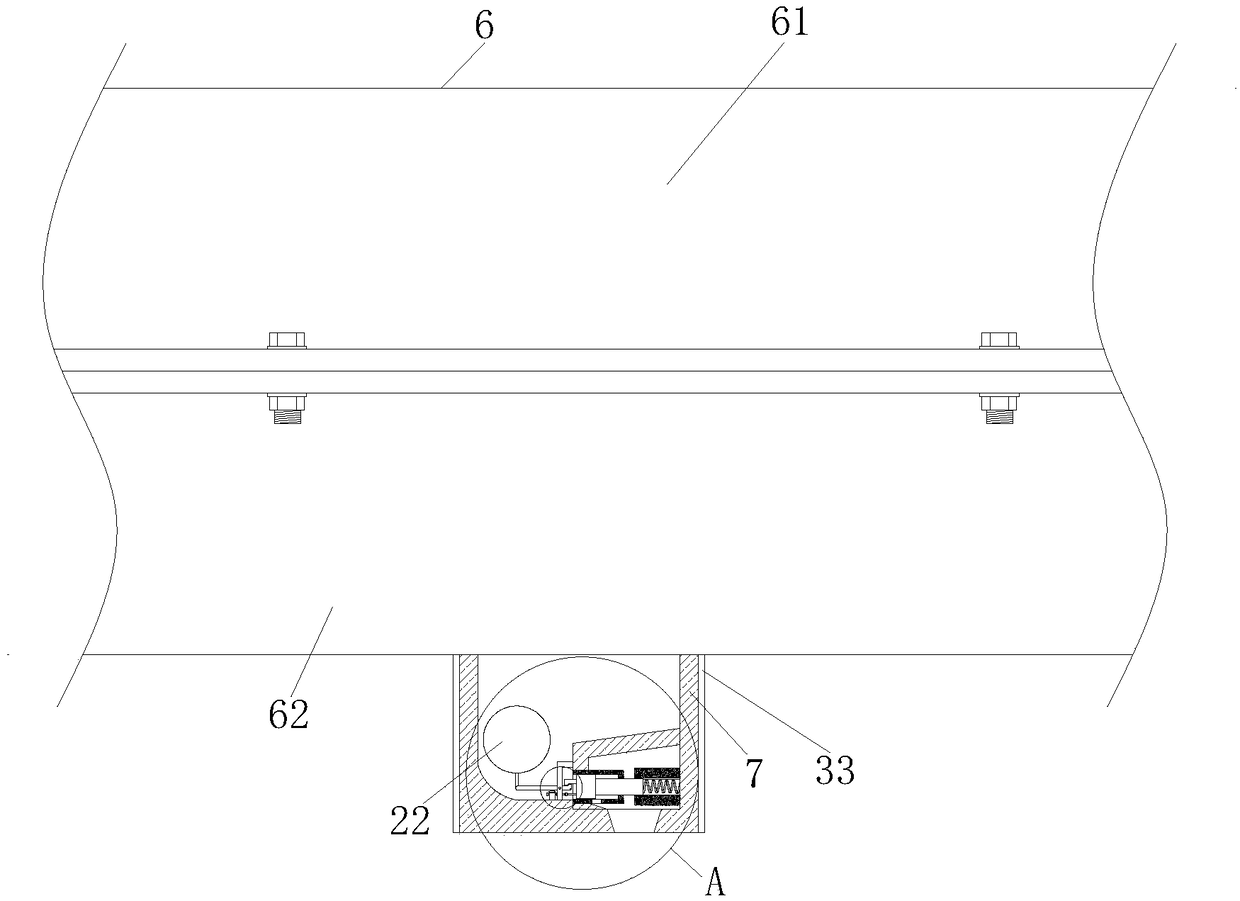

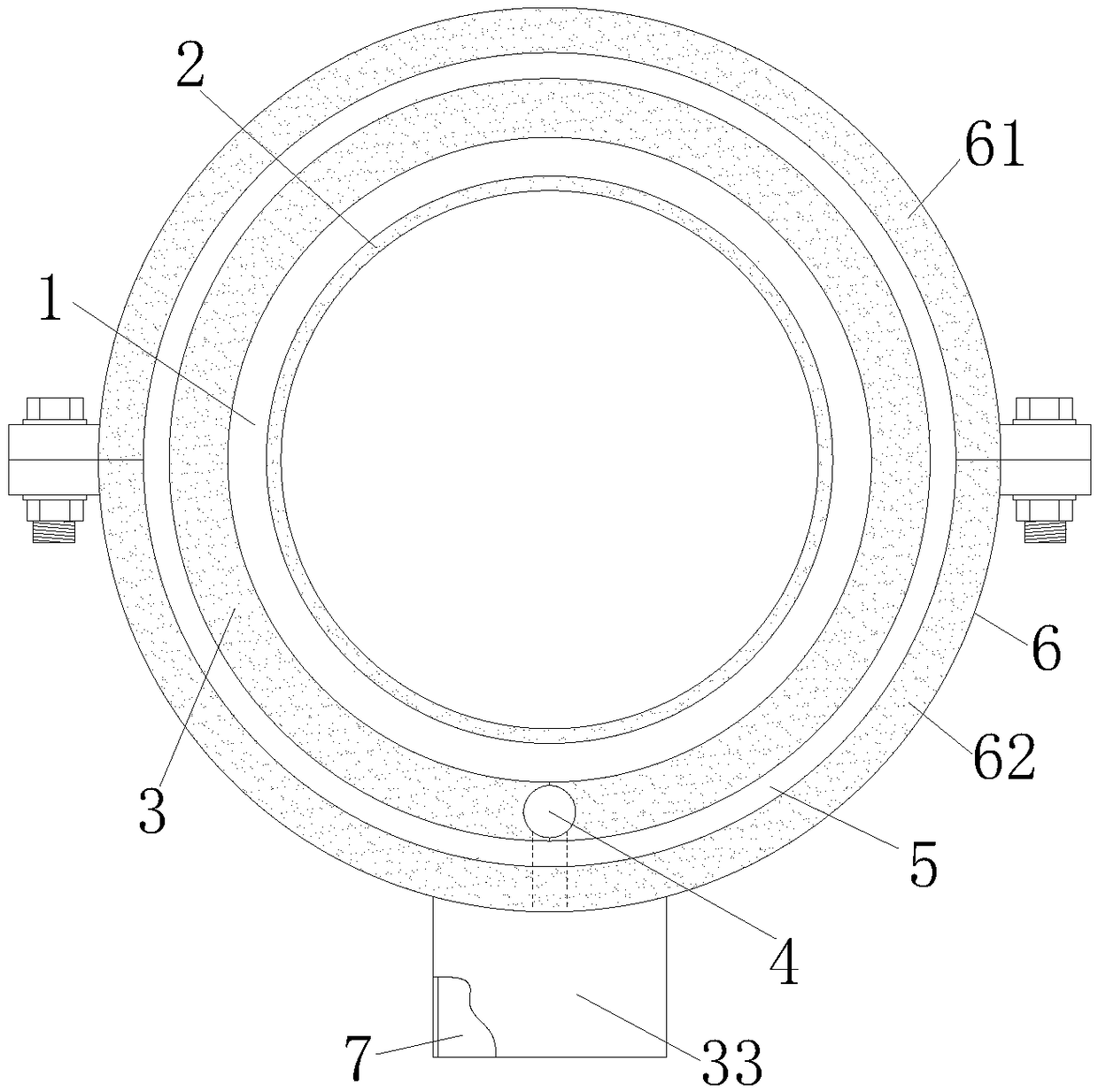

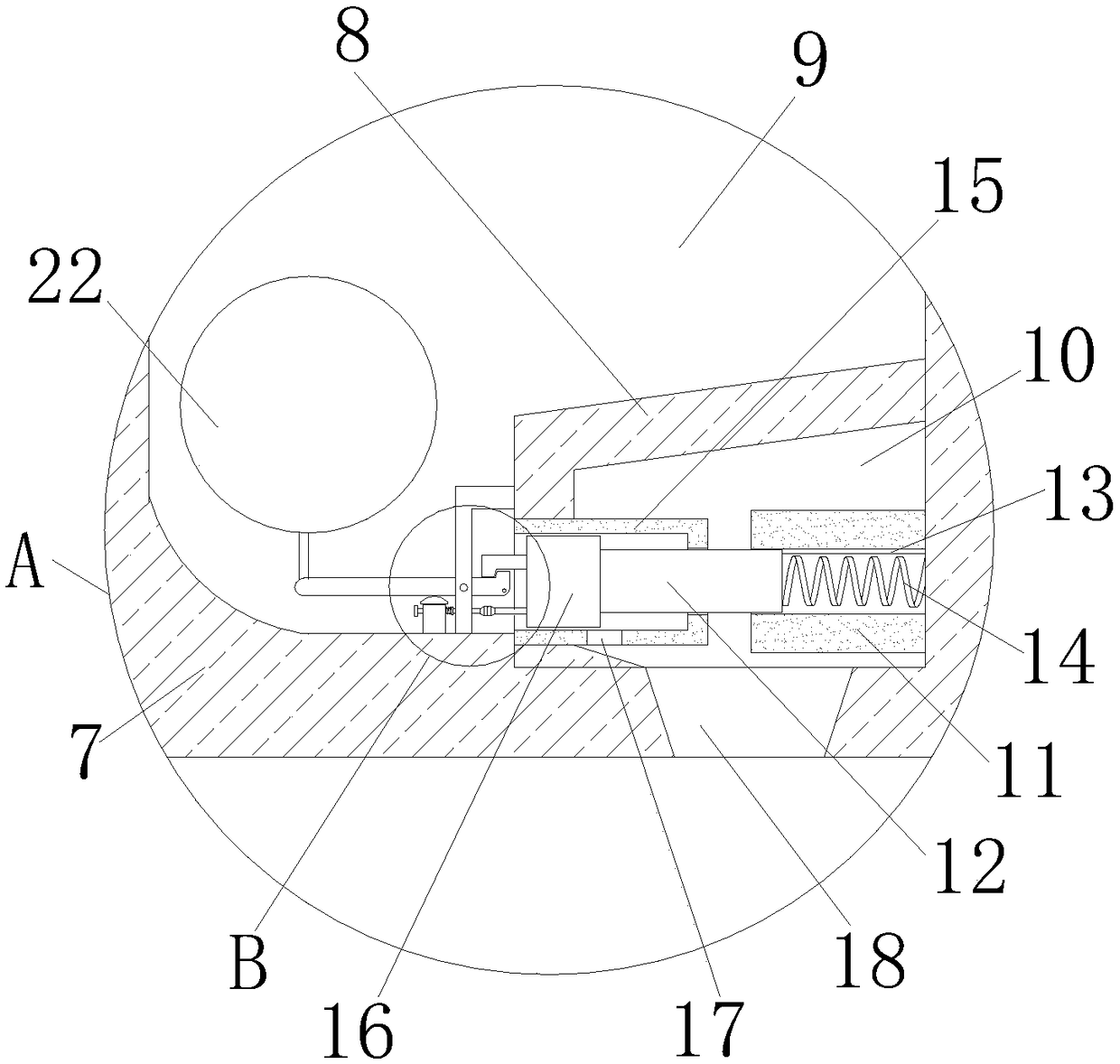

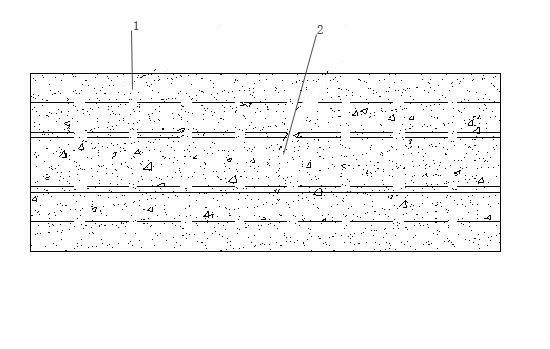

Steam conveying energy-saving thermal-insulation pipeline used for zinc sulfate production

InactiveCN109237144AAvoid affecting the insulation effectAvoid churnOperating means/releasing devices for valvesThermal insulationSulfateThermal insulation

The invention discloses a steam conveying energy-saving thermal-insulation pipeline used for zinc sulfate production. The steam conveying energy-saving thermal-insulation pipeline comprises a horizontal conveying pipe, the inner wall of the horizontal conveying pipe is coated with an anticorrosive layer, the outer wall of the horizontal conveying pipe is sleeved with a thermal-insulation layer, awater diversion groove is formed in the bottom of the thermal-insulation layer, the outer surface of the thermal-insulation layer is sleeved with a damp-proof layer, and the outer surface of the damp-proof layer is sleeved with an outer protective barrel. Accumulated water flowing into a drainage pipe is automatically discharged and prevented from accumulating in the thermal-insulation layer and reducing the effect of thermal insulation; through the outer protective barrel and the damp-proof layer, the thermal-insulation layer is wrapped, it is avoided that the temperature of steam is lost inpenetration into the thermal-insulation layer and external temperature affects the temperature of the steam inside the pipe, and accordingly the effect of thermal insulation is improved. Meanwhile, the inner wall of the horizontal conveying pipe is coated with the anticorrosive layer, in this way, the corrosion resistance of the horizontal conveying pipe is improved, the service life of the horizontal pipe is prolonged, and the period of thermal-insulation effectiveness is prolonged. Nuts are detached to separate an upper protective wall and a lower protective wall to replace the thermal-insulation layer, so that maintaining is convenient.

Owner:江西神叶实业有限公司

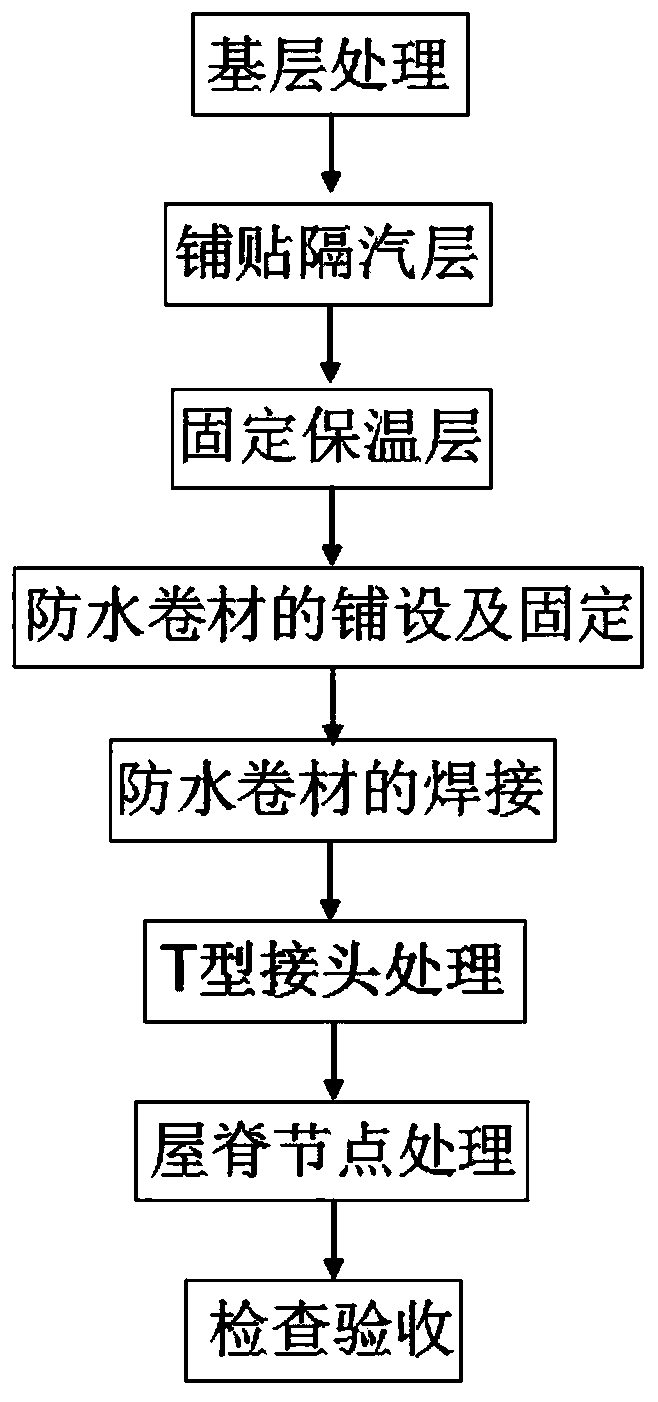

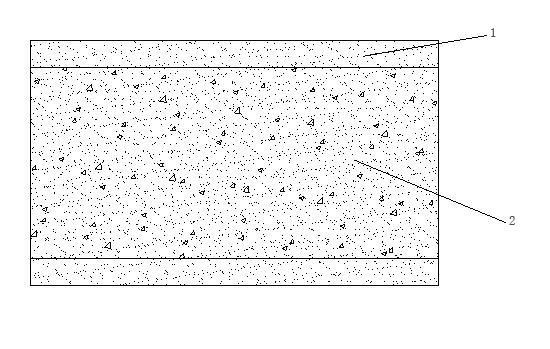

House roof waterproof construction technology based on waterproof rolls

InactiveCN109944399ALight in massReduce the level of structureRoof covering using flexible materialsBuild-up roofsPurlinVapor barrier

The invention relates to the technical field of building waterproof construction, in particular to a house roof waterproof construction technology based on waterproof rolls. The technology includes the following steps of (1) base layer processing; (2) vapor barrier laying; (3) insulating layer fixing; (4) waterproof roll laying and fixing; (5) waterproof roll welding; (6) T-joint processing; (7) ridge joint processing, wherein on the two sides of the ridge, U-shaped battens and steel truss purlins are placed at the upper ends of the reinforcing rib TPO waterproof rolls and the lower ends of profiled steel sheets respectively and are vertically fixed through bolts and nuts, the splicing seams of insulating layers are filled with polyurethane foam, and the additional reinforcing rib TPO waterproof rolls are laid; (8) inspection and acceptance. The technology has the advantages of simple structure and convenient operation, and the construction process is high in safety and free of pollution; by using the reinforcing rib TPO waterproof rolls for carrying out waterproof construction on the roof, especially the ridge, the waterproof effect is strong, and the durability is good.

Owner:QINGDAO NO 1 CONSTR GRP

Heat-preserving and cooling dual-purpose cup

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

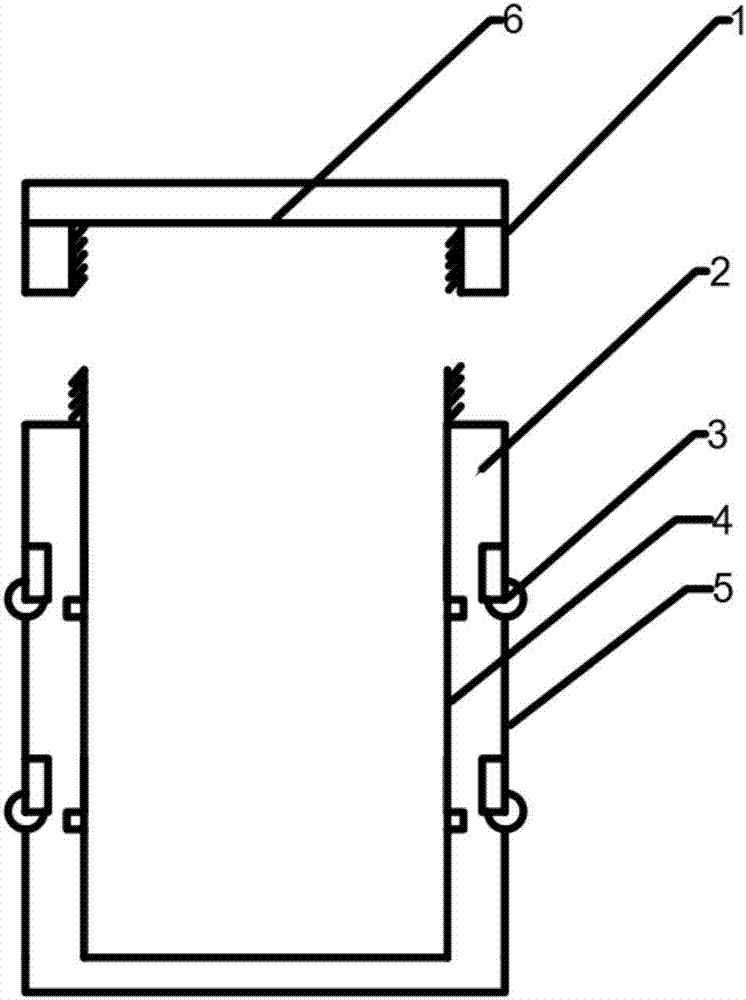

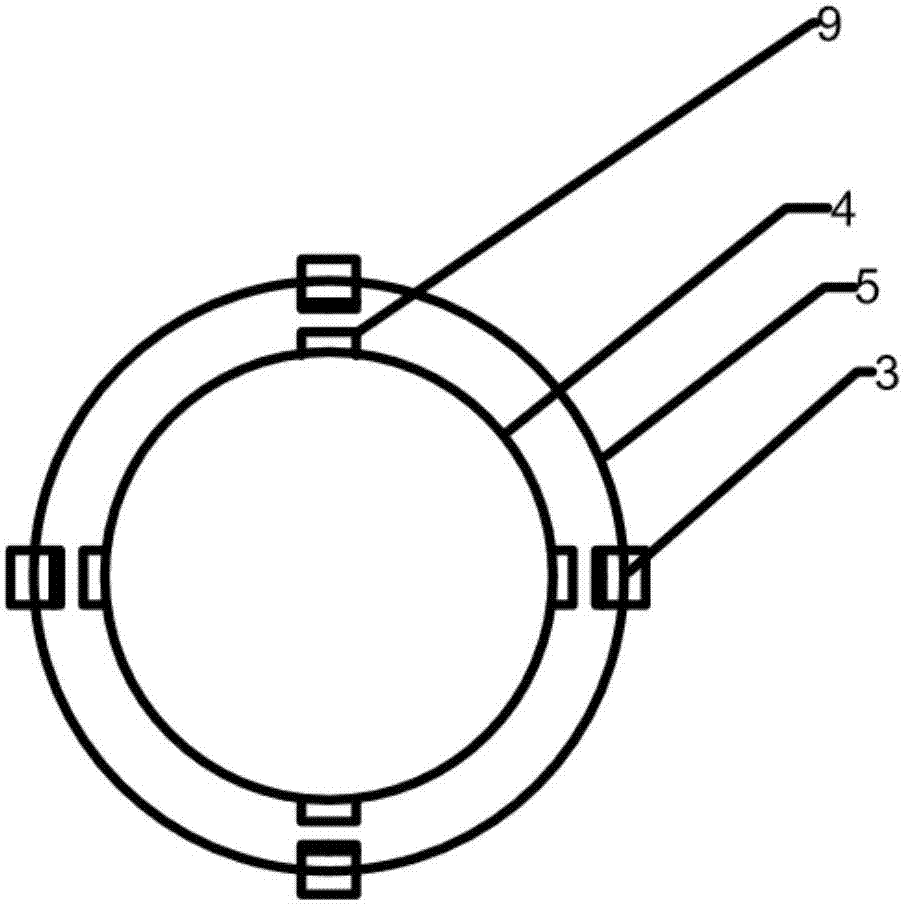

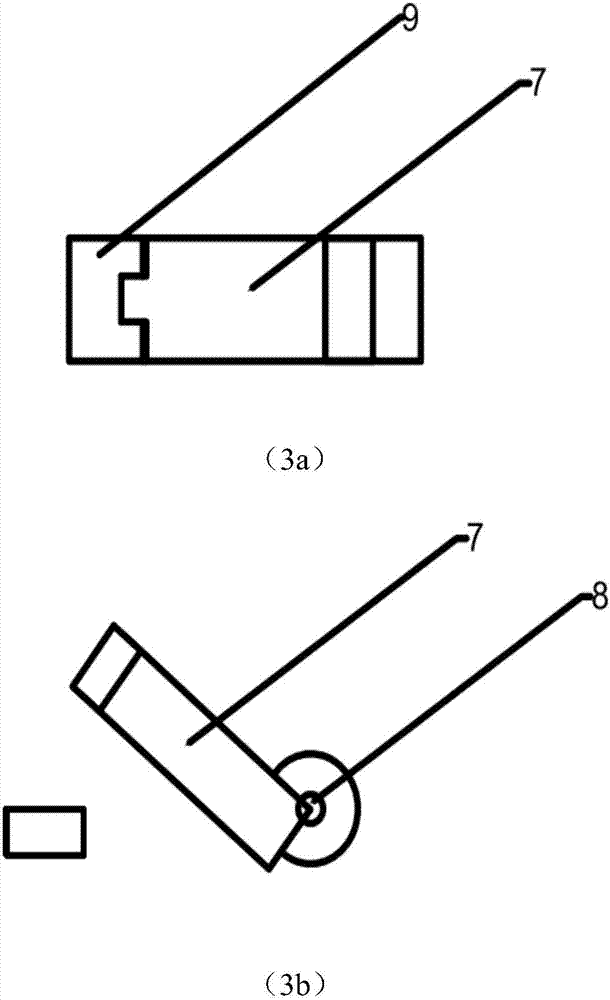

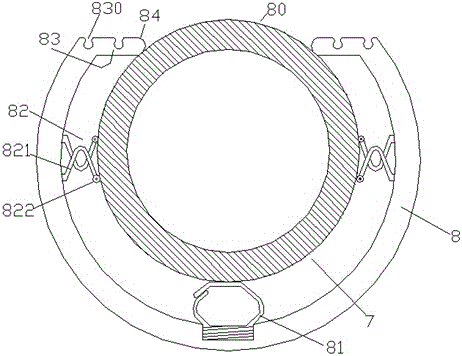

New protective cover device for pipeline and installation method of new protective cover device

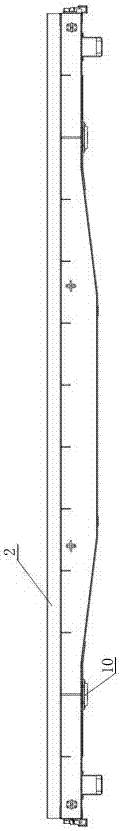

ActiveCN105864572APlay the role of heat insulation protectionPrevent loosening and fallingPipe supportsPipe protection against damage/wearPipe fittingLine segment

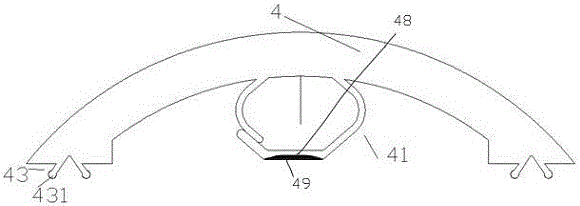

The invention discloses a new protective cover device for a pipeline and an installation method of the new protective cover device. The device is used for sleeving the pipeline (7) to play a role of heat insulation protection, and comprises a main protective part (8) taken as a larger segment part section cylinder and a cover body part (4) taken as a smaller segment part section cylinder which can be combined to form a cylinder, wherein elastic vertically-opposite platform pipe fittings (81, 41) are symmetrically arranged at the bottom of the main protective part (8) and the top of the cover body part (4), and elastic clamp components (82) are symmetrically arranged on two relative sides in the diameter direction of the main protective part (8), so that the two elastic vertically-opposite platform pipe fittings (81, 41) can clamp the pipeline (7) in the vertical direction.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Cable with protective cover and assembly and installation method of cable

InactiveCN105957626ANot easy to break awayAvoid squeezingInsulated cablesCable/conductor manufacturePipe fittingStructural engineering

A cable with a protective cover and an assembly and installation method thereof, the cable includes a cable body (7) composed of a cable core (71) and an insulating wrapping layer (72) and a heat-insulating protective cover, wherein the insulating The heat shield includes a main accommodating part (8) serving as a cylinder of a larger circular section and a cover part (4) serving as a cylinder of a smaller circular section that can be combined to form a cylinder, wherein the main accommodating part The bottom of (8) and the top of the cover part (4) are symmetrically provided with elastic countertop platform pipes (81, 41), and the diametrically opposite parts of the main accommodation part (8) are symmetrically provided There are elastic clip parts (82).

Owner:曲旭贵

Pipeline protective cover device high in protection performance and installation method thereof

ActiveCN106090533AEasy to maintain and replaceNot easy to dropThermal insulationCorrosion preventionPipe fittingPetroleum engineering

The invention provides a pipeline protective cover device high in protection performance and an installation method thereof. The pipeline protective cover device is used for being arranged outside a pipeline (7) in a sleeving mode to achieve a heat-insulation protection function. The pipeline protective cover device comprises a main protective part (8) and a cover body part (4), wherein the main protective part (8) and the cover body part (4) can be combined to form a cylinder, the main protective part (8) serves as a large round notch section column, and the cover body part (4) serves as a small round notch section column. Elastic opposite-vertex platform pipe fittings (81 and 41) are symmetrically arranged at the bottom of the main protective part (8) and the top of the cover body part (4). Elastic clamp assemblies (82) are symmetrically arranged on the two opposite sides, in the diameter direction, of the main protective part (8). Vertical clamping of the pipeline (7) can be achieved through the two elastic opposite-vertex platform pipe fittings (81 and 41).

Owner:中交河海工程有限公司

Stably mounted and clamped cable equipped with thermal-insulating protection cover and assembling and mounting method for cable

The invention discloses a stably mounted and clamped equipped with a thermal-insulating protection cover and an assembling and mounting method for the cable. The cable comprises a cable core body (7) consisting of a cable core part (71) and an insulating wrapping layer (72), and the thermal-insulating protection cover, wherein the thermal-insulating protection cover comprises a main accommodating part (8) used as a relatively big circular-nick part section cylinder and a cover body part (4) used as a relatively small circular-nick part section cylinder, and the main accommodating part (8) and the cover body part (4) can be combined into a cylinder body, wherein elastic opposite-vertex platform pipes (81, 41) are symmetrically arranged at the bottom of the main accommodating part (8) and the top of the cover body part (4); and elastic clamping parts (82) are symmetrically arranged at the opposite positions in the diameter direction of the main accommodating part (8).

Owner:ANXI DUYUANDA PACKAGING MATERIAL CO LTD

Convenient-to-mount and dismount pipeline safety protecting cover structure and mounting method thereof

InactiveCN105864576ANot easy to dropEasy to installThermal insulationPipe protection by thermal insulationPipe fittingPetroleum engineering

The invention provides a convenient-to-mount and dismount pipeline safety protecting cover structure and a mounting method thereof. The convenient-to-mount and dismount pipeline safety protecting cover structure is used for sleeving a pipeline (7) to play heat insulating and protecting roles, and comprises a main protective part (8) serving as a larger segmental part cylinder and a cover body part (4) serving as a smaller segmental part cylinder, and the main protective part and the cover body part (4) can be combined to form a cylinder, wherein elastic opposite-vertex platform pipe fittings (81 and 41) are symmetrically arranged at the bottom of the main protective part (8) and the top of the cover body part (4); elastic clamp components (82) are symmetrically arranged on two opposite sides of the main protective part (8) in the diameter direction, and accordingly, the two elastic opposite-vortex platform pipe fittings (81 and 41) can clamp the pipeline (7) in the vertical direction.

Owner:湖北万锦科技有限公司

Safety cable with heat-insulating protective cover and assembling and installing method thereof

InactiveCN105845244ANot easy to break awayAvoid squeezingInsulated cablesCable/conductor manufacturePipe fittingEngineering

A safety cable with a heat-insulating protective cover and an assembly and installation method thereof, the cable includes a cable body (7) composed of a cable core (71) and an insulating wrapping layer (72) and a heat-insulating protective cover, wherein , the heat shield includes a main accommodating part (8) serving as a cylinder of a larger circular section and a cover part (4) serving as a cylinder of a smaller circular section that can be combined to form a cylinder, wherein the The bottom of the main accommodating part (8) and the top of the cover part (4) are symmetrically provided with elastic countertop platform pipes (81, 41), and the diametrically opposite parts of the main accommodating part (8) Elastic clip parts (82) are arranged symmetrically at the places.

Owner:ANXI DUYUANDA PACKAGING MATERIAL CO LTD

Pipeline protective cover device convenient to assemble and disassemble and assembling method thereof

ActiveCN105864573AEasy to disassembleNot easy to dropThermal insulationCorrosion preventionPipe fittingPetroleum engineering

The invention discloses a pipeline protective cover device convenient to assemble and disassemble and an assembling method thereof. The device is used for sleeving a pipeline (7) to play a heat insulation protection effect, comprises a main protection part (8) as a bigger round notch part column and a cover body part (4) as a smaller round notch part column, wherein the main protection part and the cover body part can be combined to form a cylinder; elastic propping pipe fittings (81 and 41) are symmetrically arranged at the bottom of the main protection part (8) and the top of the cover body part (4), and elastic clip assemblies (82) are symmetrically arranged on the two opposite sides in the diameter direction of the main protection part (8), so that the elastic propping pipe fittings (81 and 41) can clamp the pipeline (7) in the perpendicular direction.

Owner:中交河海工程有限公司

High temperature hot delivery steel billet transportation special vehicle chassis

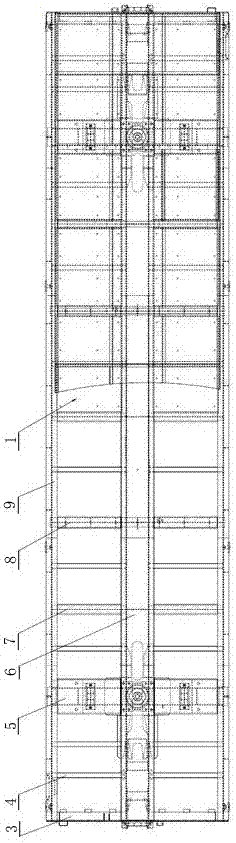

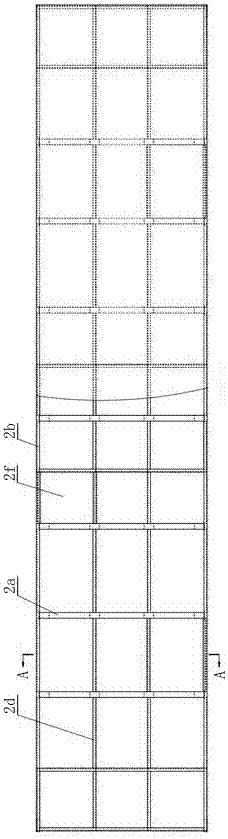

PendingCN107187454AImprove structural rigidityImprove structural strengthUnderframesAxle-box lubricationThermal insulationEngineering

The invention discloses a high temperature hot delivery steel billet transportation special vehicle chassis. The high temperature hot delivery steel billet transportation special vehicle chassis comprises a chassis component and a low-layer floor, a heat preservation thermal insulation layer assembly is arranged above the low-layer floor, and comprises a thermal insulation layer cross beam, a thermal insulation layer side beam, a thermal insulation layer support cross beam, a thermal insulation layer longitudinal beam and an upper-layer floor, the thermal insulation layer longitudinal beam is placed in the middle of the chassis and is welded to the thermal insulation layer cross beam, the thermal insulation layer cross beam and the thermal insulation layer support cross beam are assembled and welded into a simply supported beam structure, then the simply supported beam structure and the thermal insulation layer side beam are assembled and welded to form a frame-shaped grid beam structure, the frame-shaped grid beam structure is paved with the upper-layer floor, and a cavity formed by the whole frame-shaped grid beam structure is filled with a heat preservation material. The high temperature hot delivery steel billet transportation special vehicle chassis has a good heat preservation function, and the chassis is applicable to safe loading and transportation of a steel billet not higher than 700 DEG C in a steel enterprise; moreover, the thickness of the heat preservation material can be adjusted according to the temperature of the loaded and transported steel billet, therefore achieving safe loading and transportation of steel billets with different temperatures in all steel enterprises.

Owner:CRRC MEISHAN

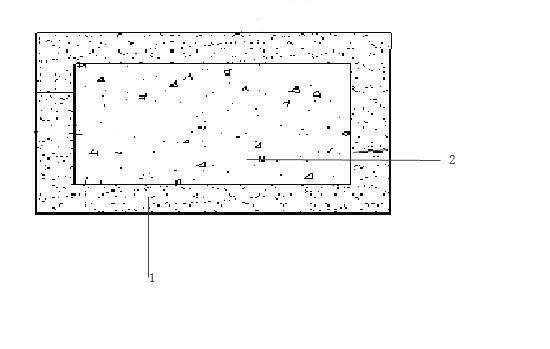

Composite heat-insulating brick system

InactiveCN102644354ASolve the effect of heat preservationAvoid affecting the insulation effectConstruction materialClimate change adaptationBrickEngineering

A composite heat-insulating brick system comprises a structure part and a heat-insulating part; the structure part comprises two L-shaped bodies which are engaged with each other; the two L-shaped bodies form a cuboid with an internal cavity; the cuboid with heat-insulating materials filled inside is the heat-insulating part. In a word, the composite system has unexampled advantages with respect to manufacturing construction, structure application, heat-insulation performance, and service life. In the excellent situation of national energetic implementation of the energy saving and emission reduction policy, the invention has extensive development space.

Owner:HOHAI UNIV

Firm pipeline protecting cover device and mounting method thereof

ActiveCN105864574APlay the role of heat insulation protectionPrevent loosening and fallingThermal insulationCorrosion preventionThermal insulationPipe fitting

The invention relates to a firm pipeline protecting cover device and a mounting method thereof. The device is arranged outside a pipeline (7) in a sleeving manner to realize a thermal insulation protection effect. The device comprises a main protecting part (8) serving as a larger circular missing part section cylinder and a cover body part (4) serving as a smaller circular missing part section cylinder; the main protecting part (8) and the cover body part (4) can be combined to form a cylinder; elastic on-top platform pipe fittings (81 and 41) are symmetrically arranged at the bottom of the main protection part (8) and the top of the cover body part (4); elastic clamp components (82) are symmetrically arranged on the two opposite sides in the diameter direction of the main protection part (8). Therefore, the two elastic on-top platform pipe fittings (81 and 41) can clamp the pipeline (7) in a perpendicular direction.

Owner:JIANGSU ASOE NEW MATERIAL TECH

Pipeline protective cover device convenient to dismantle and mount and installation method thereof

ActiveCN105972385APlay the role of heat insulation protectionPrevent loosening and fallingThermal insulationCorrosion preventionThermal insulationPipe fitting

The invention discloses a pipeline protective cover device convenient to dismantle and mount and an installation method thereof. The pipeline protective cover device is used for being arranged at the external part of a pipeline (7) in a sleeving manner to play the role in thermal insulation and protection and comprises a main protective part (8) serving as a larger segmental part sectional cylinder and a cover body part (4) serving as a smaller segmental part sectional cylinder, and the main protective part and the cover body part can be combined to form a cylinder, wherein the bottom of the main protective part (8) and the top of the cover body part (4) are symmetrically provided with elastic opposite vertex platform pipe fittings (81, 41); elastic clamp components (82) are symmetrically arranged on two opposite sides of the main protective part (8) in the diameter direction; therefore, the two elastic opposite vertex platform pipe fittings (81, 41) can clamp the pipeline (7) in the vertical direction.

Owner:JIANGSU ASOE NEW MATERIAL TECH

Pipeline protection cover device firm in installation and installing method for pipeline protection cover device firm in installation

ActiveCN105840953APlay the role of heat insulation protectionPrevent loosening and fallingThermal insulationCorrosion preventionEngineering

The invention discloses a pipeline protection cover device firm in installation and an installing method for the pipeline protection cover device firm in installation. The device is used for being arranged outside the pipeline (7) in a sleeving manner to play a heat isolation and protection role. The device comprises a main protection part (8) serving as a large circle flaw section cylinder and a cover part (4) serving as a small circle flaw section cylinder, wherein the main protection part (8) and the cover part (4) can be combined to form a cylinder. Elastic opposite vertex platform pipes (81 and 41) are symmetrically arranged at the bottom of the main protection part (8) and on the top of the cover part (4). Elastic clamp assemblies (82) are symmetrically arranged on the two opposite sides of the main protection part (8) in the diameter direction. Accordingly, the two elastic opposite vertex platform pipes (81 and 41) can clamp the pipeline (7) in the vertical direction.

Owner:JIANGSU FORGED PIPE FITTINGS

Firmly installed cable with heat-insulating protective cover and assembly and installation method of cable

InactiveCN105957618AEasy to installNot easy to break awayInsulated cablesCable/conductor manufacturePipe fittingEngineering

The invention provides a firmly installed cable with a heat-insulating protective cover and an assembly and installation method of the cable. The cable comprises a cable body (7) and the heat-insulating protective cover, wherein the cable body (7) comprises a cable core part (71) and an insulated wrapping layer (72); the heat-insulating protective cover comprises a main accommodating part (8) as a cylinder body of a relatively large segment part section and a cover body part (4) as the cylinder body of a relatively small segment part section; the main accommodating part (8) and the cover body part (4) can be combined to form the cylinder body; elastic jacking platform pipe fittings (81 and 41) are symmetrically arranged at the bottom part of the main accommodating part (8) and the top part of the cover body part (4); and elastic clamp components (82) are symmetrically arranged at the opposite parts, in the diameter direction, of the main accommodating part (8).

Owner:ANXI DUYUANDA PACKAGING MATERIAL CO LTD

Cable convenient to assemble and having heat insulation protective cover and assembling installing method thereof

InactiveCN106128590AEasy to assembleNot easy to break awayInsulated cablesCable/conductor manufacturePipe fittingPetroleum engineering

The invention discloses a cable convenient to assemble and having a heat insulation protective cover and an assembling installing method thereof. The cable comprises a cable body (7) and the heat insulation protective cover, wherein the cable body consists of a cable core part (71) and an insulated wrapping layer (72), the heat insulation protective cover comprises a main accommodating part (8) as a relatively big round flaw section cylinder body and a cover body part (4) as a relatively small round flaw section cylinder body, and the main accommodating part (8) and the cover body part (4) can be combined to form a cylinder body; elastic opposite vertex platform pipe fittings (81, 41) are symmetrically arranged at the bottom of the main accommodating part (8) and on the top of the cover body part (4); and elastic clamp components (82) are symmetrically arranged at opposite positions in the diameter direction of the main accommodating part (8).

Owner:ANXI DUYUANDA PACKAGING MATERIAL CO LTD

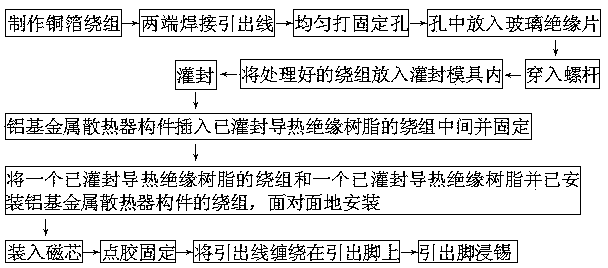

Low-voltage large-current and high-power inductor and installation method thereof

InactiveCN104299755AReduce skin effectSmall footprintTransformers/inductances coolingInductances/transformers/magnets manufactureLow voltageCopper foil

The invention discloses a low-voltage large-current and high-power inductor. A structural magnetic core is installed in an aluminum-based metal radiator component which is installed in a winding, terminal pins are arranged on the left side and the right side of the bottom of the winding, and an arc contact surface capable of slightly deforming inside the aluminum-based metal radiator component is arranged between two cooling fins at the top of the aluminum-based metal radiator component and located inside a center column. The low-voltage large-current and high-power inductor has the advantages that the skin effect is reduced, the occupation height is reduced compared with a strand wire, and the structure is simple; small holes are formed in copper foil at equal intervals, screw rods made of materials not sensitive to filling and sealing of thermal conductive and insulating materials penetrate through the small holes and a glass insulation sheet to be fixed, the copper foil is separated to prevent short-circuiting, and the winding has the minimum thickness; the copper foil is arranged in a die with a diversion trench, the thermal conductive and insulating materials are used for filling and sealing, and the slight vibration and vacuumizing mode can prevent bubbles generated in the filling and sealing process from affecting the insulation effect; the arc contact surface can increase the contact area between a radiator and the magnetic core and improve the thermal conductive capacity.

Owner:深圳市中电熊猫磁通电子有限公司

A pipeline safety protective cover device and its installation method

ActiveCN105972383BNot easy to dropEasy to installThermal insulationCorrosion preventionEngineeringMechanical engineering

The invention provides a safety protection cover device for a pipeline and a mounting method of the device. The device sleeves the outer part of the pipeline (7) and can play the heat insulation and protection effects. The device comprises a main protecting part (8) which is treated as a large segmental section of a cylinder, and a cover body part (4) which is treated as a small segmental section of the cylinder, wherein the main protecting part (8) and the cove body part (4) can be combined to form the cylinder; elastic opposite-propping platform pipes (81, 41) are symmetrically arranged at the bottom part of the main protecting part (8) and the top part of the cover body part (4); elastic clamp assemblies (82) are symmetrically arranged at two opposite sides, in the diameter direction, of the main protecting part (8); the two elastic opposite-propping platform pipes (81, 84) can be used for clamping the pipeline (7) in the vertical direction.

Owner:江苏双钦新材料科技有限公司

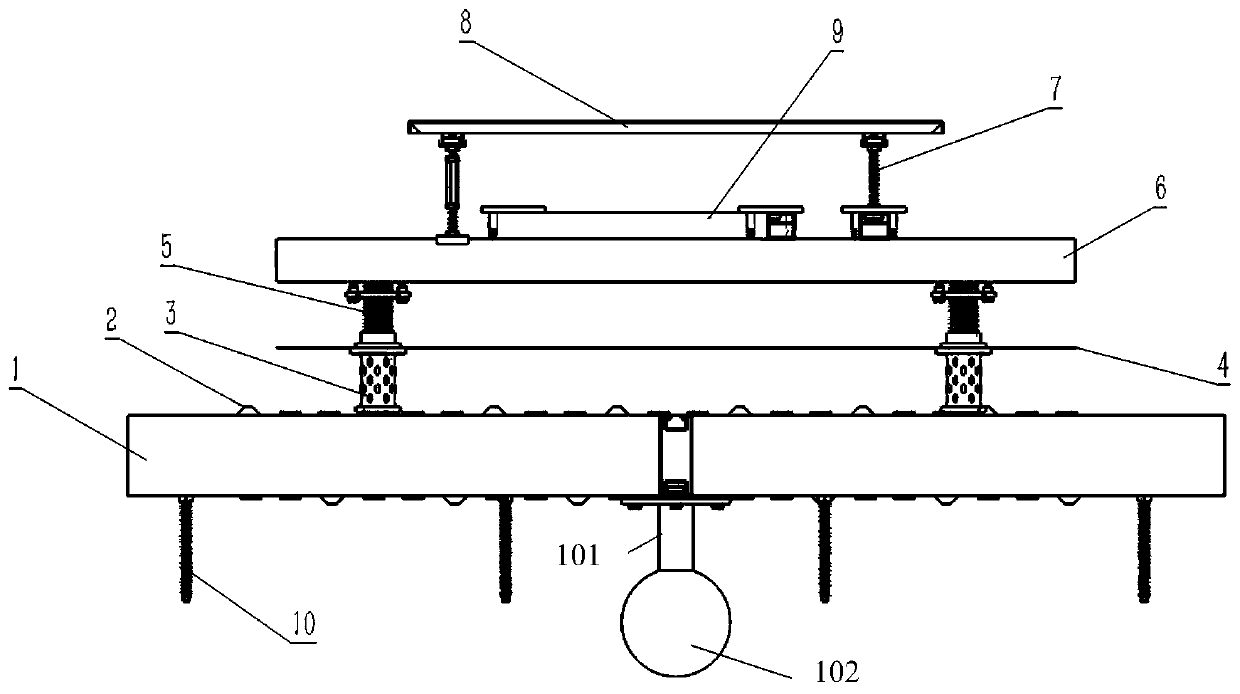

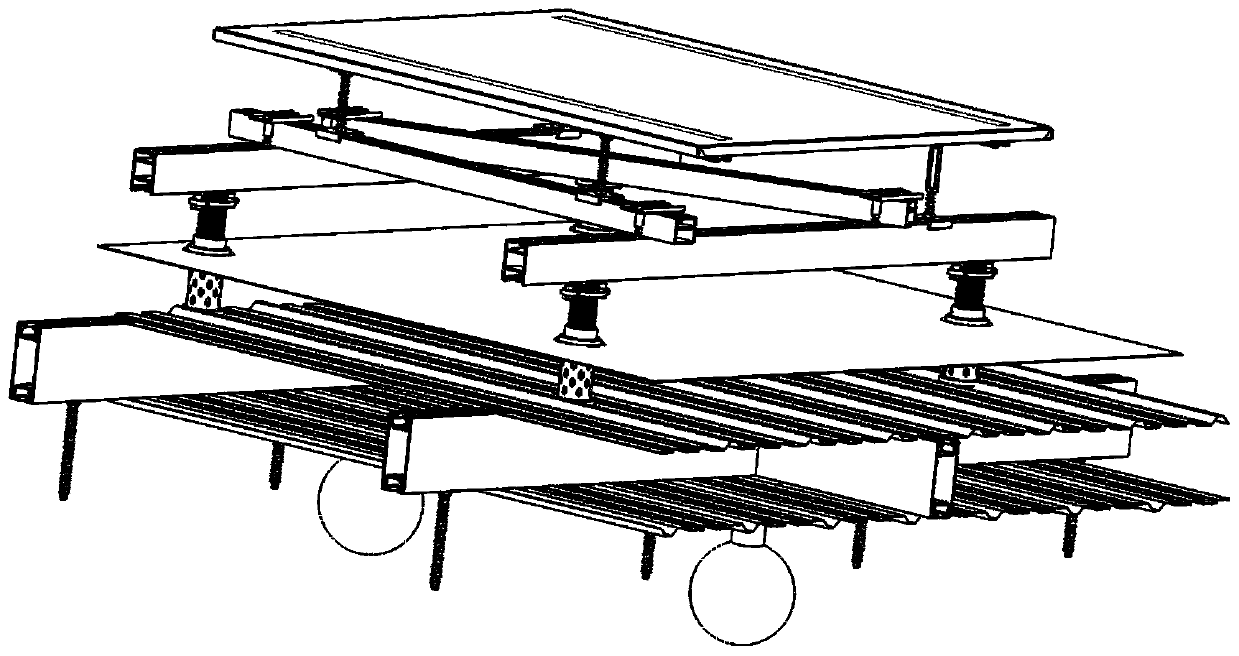

Building system suitable for constructing curved surfaces and having moisture emission function

PendingCN110629921APresent aestheticsSolve the installationCeilingsBuilding insulationsInsulation layerMoisture

The invention discloses a building system suitable for constructing curved surfaces and having a moisture emission function, and belongs to the technical field of buildings. The building system comprises a building face plate, a supporting beam composed of a plurality of purlines I, a mounting plate mounted on the supporting beam, a heat-insulation layer laid on the mounting plate, a waterproof layer, exhausting vertical columns, threaded columns, a plurality of purlines II and adjusting assemblies, wherein the waterproof layer, the exhausting vertical columns, the threaded columns, the purlines II and the adjusting assemblies are laid on the heat-insulation layer; the exhausting vertical columns are provided with cavities with the open tops, and the side faces, surrounding the cavities, of the vertical columns are provided with moisture emission holes communicating with the heat-insulation layer; the tops of the exhausting vertical columns are connected with the bottoms of the threaded columns through threads, wherein the threaded columns are provided with cavities as well; the tops of the threaded columns are connected with the purlines II, and the upper parts of the purlines IIare connected with the adjusting assemblies; and the bottom of the building face plate is connected with the multiple adjusting assemblies, and the telescopic length of screws of the adjusting assemblies is changed to change the mounting position status of the building face plate. According to the building system, the problems of moisture emission of the heat-insulating layer and angle adjusting of the building face plate can be solved.

Owner:黑龙江施耐达建筑技术有限公司

Anti-wear cable with heat-insulating protective cover and assembling-mounting method thereof

InactiveCN105869754ANot easy to break awayAvoid squeezingInsulated cablesCable/conductor manufacturePipe fittingStructural engineering

The invention discloses an anti-wearing cable with a heat-insulating protective cover and an assembling-mounting method thereof. The cable comprises a cable body (7) consisting of a cable core part (71) and an insulating wrapping layer (72), wherein the heat-insulating protective cover comprises a main accommodating part which can be combined into a cylinder to serve as a large indent segment cylinder body, and a cover part (4) serving as a small indent segment cylinder body; elastic counter-jack platform pipe fittings (81 and 41) are symmetrically arranged at the bottom of the main accommodating part (8) and on the top of the cover part (4); elastic clamping components (82) are symmetrically arranged at opposite positions in the diameter direction of the main accommodating part (8).

Owner:方倩

Safe cable with heat insulation protective cover and assembling installing method thereof

InactiveCN106128592ANot easy to break awayAvoid squeezingInsulated cablesCable/conductor manufacturePipe fittingPetroleum engineering

The invention discloses a safe cable with a heat insulation protective cover and an assembling installing method thereof. The cable comprises a cable body (7) and the heat insulation protective cover, wherein the cable body consists of a cable core part (71) and an insulated wrapping layer (72), the heat insulation protective cover comprises a main accommodating part (8) as a relatively big round flaw section cylinder body and a cover body part (4) as a relatively small round flaw section cylinder body, and the main accommodating part (8) and the cover body part (4) can be combined to form a cylinder body; elastic opposite vertex platform pipe fittings (81, 41) are symmetrically arranged at the bottom of the main accommodating part (8) and on the top of the cover body part (4); and elastic clamp components (82) are symmetrically arranged at opposite positions in the diameter direction of the main accommodating part (8).

Owner:ANXI DUYUANDA PACKAGING MATERIAL CO LTD

Cable structure for communication, and assembling and mounting method therefor

InactiveCN106128586ANot easy to break awayAvoid squeezingCommunication cablesInsulated cablesEngineeringMechanical engineering

The invention discloses a cable structure for communication and an assembling and mounting method therefor. The cable comprises a cable body (7) which consists of a cable core part (71) and an insulating wrapping layer (72), and a thermal-insulating protection cover, wherein the thermal-insulating protection cover comprises a main accommodating part (8) which is used as a relatively big segment part section cylinder and a cover body part (4) which is used as a relatively small segment part section cylinder, and the main accommodating part (8) and the cover body part (4) can be combined into a cylinder body, wherein elastic opposite propping platform pipes (81, 41) are symmetrically arranged at the bottom of the main accommodating part (8) and the top of the cover body part (4); and elastic clamping parts (82) are symmetrically arranged at the opposite positions in the diameter direction of the main accommodating part (8).

Owner:方倩

A kind of firmly installed pipeline protective cover device and its installation method

The invention discloses a pipeline protection cover device firm in installation and an installing method for the pipeline protection cover device firm in installation. The device is used for being arranged outside the pipeline (7) in a sleeving manner to play a heat isolation and protection role. The device comprises a main protection part (8) serving as a large circle flaw section cylinder and a cover part (4) serving as a small circle flaw section cylinder, wherein the main protection part (8) and the cover part (4) can be combined to form a cylinder. Elastic opposite vertex platform pipes (81 and 41) are symmetrically arranged at the bottom of the main protection part (8) and on the top of the cover part (4). Elastic clamp assemblies (82) are symmetrically arranged on the two opposite sides of the main protection part (8) in the diameter direction. Accordingly, the two elastic opposite vertex platform pipes (81 and 41) can clamp the pipeline (7) in the vertical direction.

Owner:JIANGSU FORGED PIPE FITTINGS

Safety protection cover device for pipeline and mounting method of device

ActiveCN105972383APlay the role of heat insulation protectionPrevent loosening and fallingThermal insulationCorrosion preventionEngineering

The invention provides a safety protection cover device for a pipeline and a mounting method of the device. The device sleeves the outer part of the pipeline (7) and can play the heat insulation and protection effects. The device comprises a main protecting part (8) which is treated as a large segmental section of a cylinder, and a cover body part (4) which is treated as a small segmental section of the cylinder, wherein the main protecting part (8) and the cove body part (4) can be combined to form the cylinder; elastic opposite-propping platform pipes (81, 41) are symmetrically arranged at the bottom part of the main protecting part (8) and the top part of the cover body part (4); elastic clamp assemblies (82) are symmetrically arranged at two opposite sides, in the diameter direction, of the main protecting part (8); the two elastic opposite-propping platform pipes (81, 84) can be used for clamping the pipeline (7) in the vertical direction.

Owner:江苏双钦新材料科技有限公司

A kind of pipeline heat insulation protective cover and its installation method

ActiveCN105889701BNot easy to dropEasy to installPipe protection against damage/wearEngineeringPerpendicular direction

The invention discloses a heat-insulation and protective cover for a pipe and an installing method thereof. The heat-insulation and protective cover is used for being arranged outside a pipe (7) in a sleeving mode to achieve the heat-insulation effect and the protective effect, and comprises a main protective part (8) capable of being merged to form a cylinder and serving as a large incomplete-part-section column and a cover part (4) serving as a small incomplete-part-section column, wherein elastic opposite-abutting platform pipe pieces (81,41) are symmetrically arranged at the bottom of the main protective part (8) and the top of the cover part (4), elastic clamp assemblies (82) are symmetrically arranged on the two opposite sides in the diameter direction of the main protective part (8), and in this way, clamping of the pipe (7) in the perpendicular direction can be formed through the two elastic opposite-abutting platform pipe pieces (81,41).

Owner:温州元鼎铜业有限公司

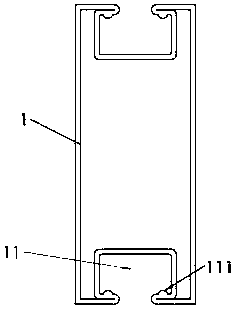

Waterproof door and window beam aluminum profile

PendingCN108930485AAvoid corrosionFix damageCondensed water drain-offSealing arrangementsCorrosionEngineering

The invention relates to the field of doors and windows, in particular to a waterproof door and window beam aluminum profile. The waterproof door and window beam aluminum profile comprises a supporting frame with a supporting cavity in the middle, a glass connection portion disposed at the upper end of the outer side of the supporting frame and a sealing connection portion disposed at the lower end of the outer side of the supporting frame, and the supporting frame, the glass connecting portion and the sealing connecting portion are integrally formed; a drainage hole is formed in the outer side of the glass connecting portion, so that accumulated water can be discharged in time to avoid corrosion to a door and window frame body, and an apron flashing is connected to the outer side of the sealing connecting portion in a clamped mode; and the apron flashing is located below the drainage hole, a drainage plate extending outwards and inclined downwards is arranged at the upper end of the apron flashing to guide the discharged accumulated water to the outer portion of a window and avoid secondary pollution caused by sputtering to doors and windows, damage to the doors and windows by rainwater is effectively avoided, and the service life of the doors and windows is prolonged.

Owner:TIANJIN RIYUE DOOR & WINDOW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com